Textile printing and dyeing wastewater treatment device

A waste water treatment, textile printing and dyeing technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as equipment blockage, high cost, and environmental pollution. To achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

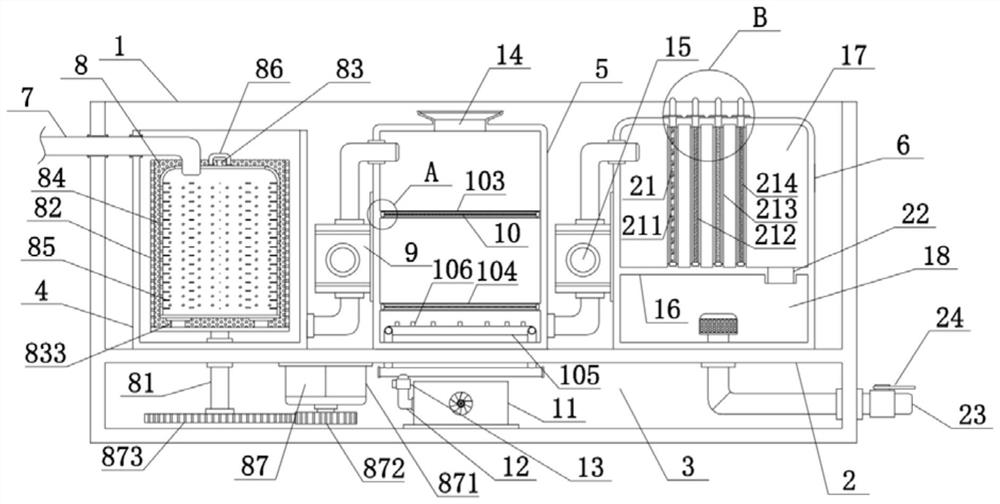

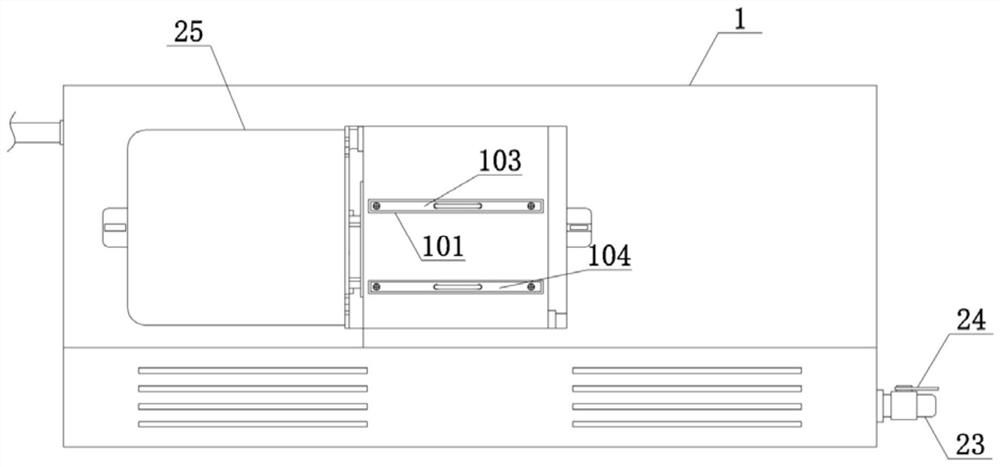

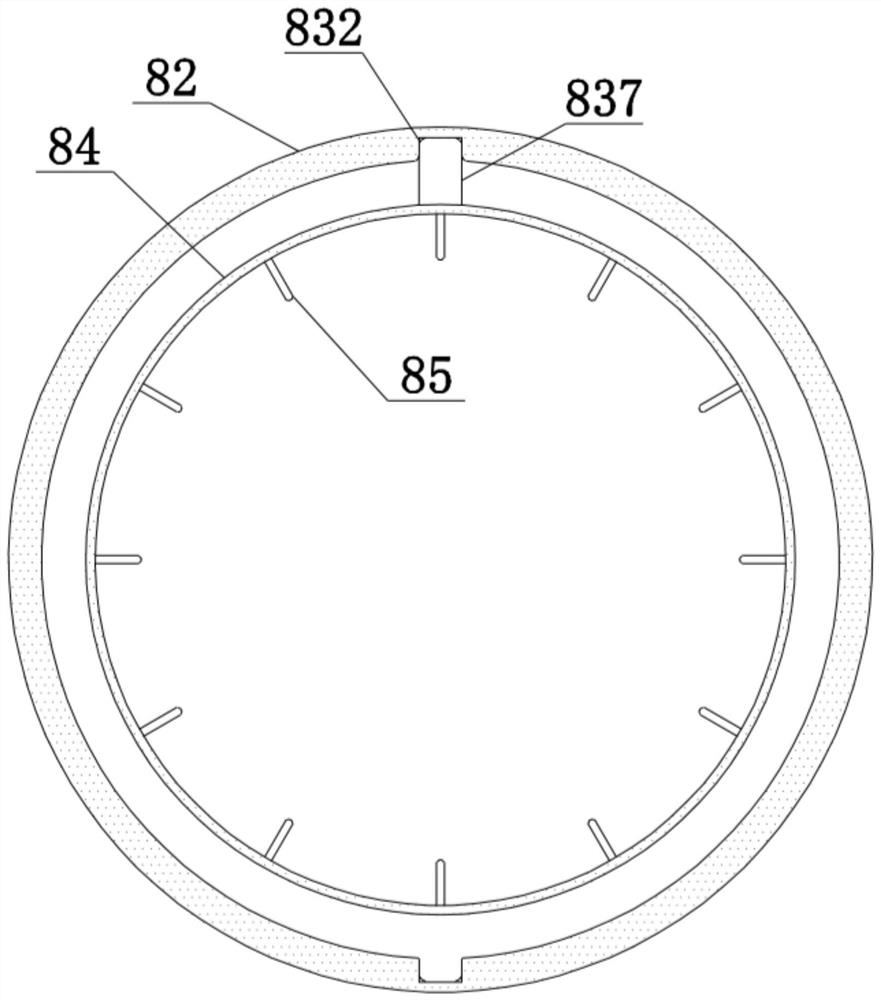

[0033] see figure 1 and figure 2 , a wastewater treatment device for textile printing and dyeing, comprising a device body 1, a fixing plate 2 is fixedly installed on the inner bottom of the device body 1, and an electrical room 3 is separated from the inner bottom of the device body 1 through the fixing plate 2, so that The upper end of the fixed plate 2 is fixedly installed with the line removal cylinder 4, the sedimentation chamber 5 and the water filtration chamber 6 respectively, and the side wall of the device body 1 is plugged with a water delivery pipe 7, and the water delivery pipe 7 is movable and can carry out back and forth Twitching and rotating, the water delivery pipe 7 is connected with the external pipeline through the flange, and the water delivery pipe 7 is inserted into the inside of the line removal cylinder 4, and the inside of the line removal cylinder 4 is provided with a line removal mechanism 8, and the line removal cylinder 4 The lower end of 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com