Method for predicting FRP-concrete beam interface crack length under variable amplitude fatigue

A concrete beam, crack length technology, applied in the direction of testing material strength by applying repeated force/pulsation force, testing material strength by applying stable tension/compression, measuring devices, etc., can solve the problem that there is no effective test method for the extension length of interface cracks , There are few researches on the fatigue performance of the reinforced interface with variable amplitude, etc.

Active Publication Date: 2020-10-30

JINAN UNIVERSITY

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the domestic and foreign research on FRP-strengthened concrete beams is focused on statics and constant-amplitude fatigue performance, and there are few studies on the variable-amplitude fatigue performance of the reinforced interface. no valid test method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

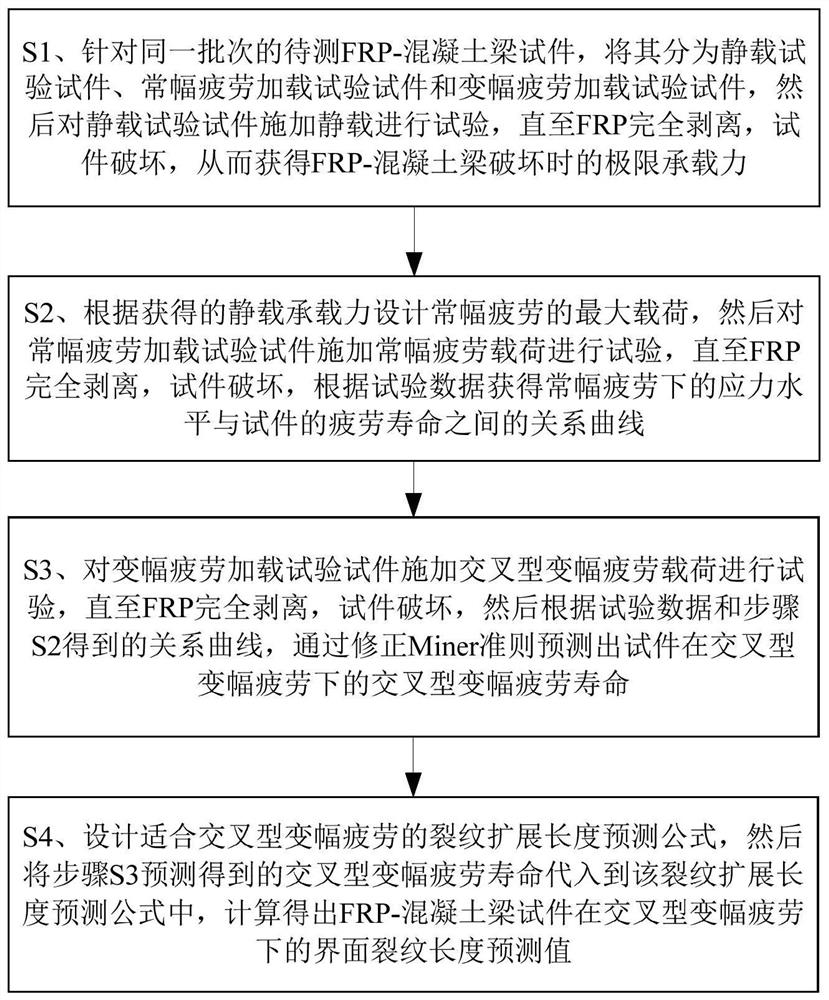

[0060] This embodiment discloses a method for predicting the crack length of the FRP-concrete beam interface under variable amplitude fatigue, such as figure 1 As shown, the steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

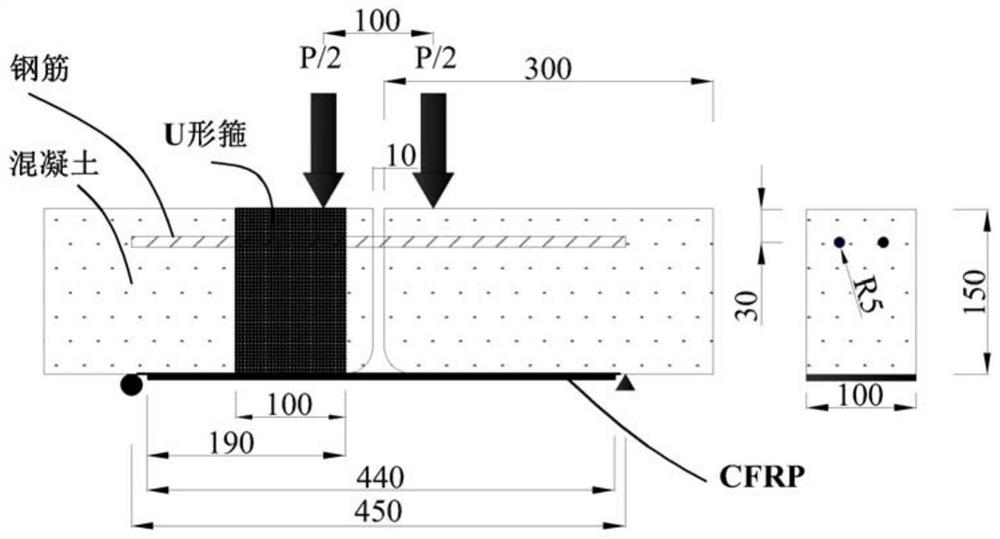

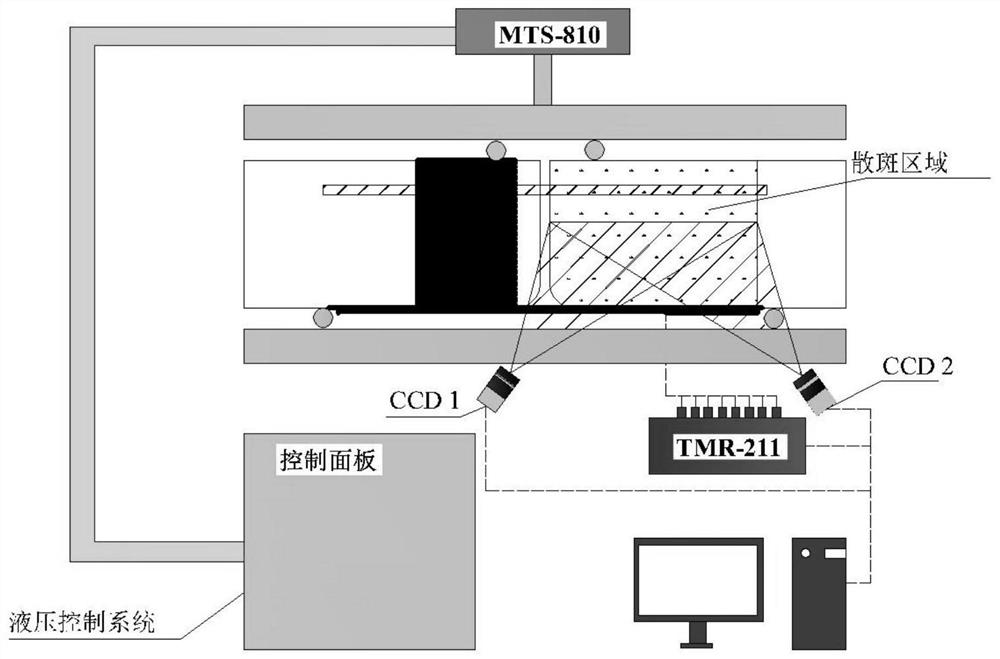

The invention discloses a method for predicting an FRP-concrete beam interface crack length under a variable amplitude fatigue. The method comprises the steps of firstly applying a static load to a static load test piece, and obtaining the ultimate bearing capacity of the FRP-concrete beam during damage, designing the maximum load of constant-amplitude fatigue according to the static load bearingcapacity, applying a constant-amplitude fatigue load to the constant-amplitude fatigue test loading test piece, and obtaining a stress-fatigue life relation curve under constant-amplitude fatigue according to test data, then applying a crossed variable-amplitude fatigue load to the variable-amplitude fatigue test loading test piece for testing, and predicting the crossed variable-amplitude fatiguelife of the test piece by correcting a Miner criterion according to test data and the obtained stress-fatigue life relation curve, and finally, designing a crack propagation length prediction formula, and substituting the crossed variable-amplitude fatigue life into the formula to obtain an interface crack length prediction value of the test piece under crossed variable-amplitude fatigue. The FRP-concrete interface crack propagation length under the crossed variable-amplitude fatigue can be accurately measured.

Description

technical field [0001] The invention relates to the technical field of performance testing of FRP-strengthened concrete beams, in particular to a method for predicting the crack length of an FRP-concrete beam interface under variable-amplitude fatigue. Background technique [0002] With the continuous development of the transportation industry, the requirements for bridge roads are getting higher and higher, and some of the existing bridge roads are concrete building structures many years ago, which cannot meet the current transportation requirements after many years of service. Therefore, these Building reinforcement is imperative. Currently, Fiber Reinforced Polymer (FRP) is introduced into the reinforcement of building structures. Attaching FRP to the bottom of the beam is the main way to strengthen the concrete beam. The FRP material is pasted on the surface of the concrete beam through resin glue to form a new reinforced beam. The reinforced beam is actually loaded by ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08G01N3/32G06F30/20G06F17/18G06F119/14

CPCG01N3/08G01N3/32G06F30/20G06F17/18G01N2203/0003G01N2203/0005G01N2203/0073G01N2203/0066G06F2119/14Y02T90/00

Inventor 袁鸿罗光云曾岚刘畅

Owner JINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com