Fixed-length cutting facility for flat steel strip of elevator

A technology of cutting device and steel strip, which is applied in metal sawing equipment, sawing machine equipment, metal processing equipment, etc., to avoid manual length measurement and improve the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

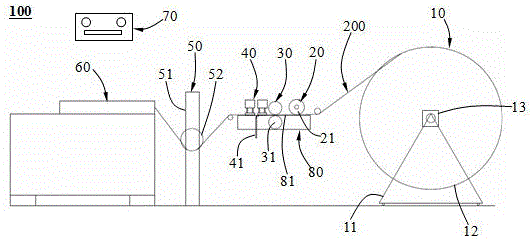

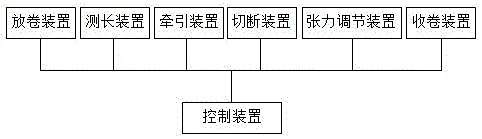

[0018] see figure 1 As shown, the present invention provides a fixed-length cutting equipment 100 for an elevator flat steel belt, including an unwinding device 10, a length measuring device 20, a traction device 30, and a cutting device 40 arranged in sequence along the conveying direction of the flat steel belt 200. , a tension adjusting device 50, a winding device 60, and a control device 70 connected to the aforementioned various devices.

[0019] The unwinding device 10 is provided with a base 11 and a reel 12 fixed on the base 11. The reel 12 is used for winding the flat steel strip 200 and is provided with a central shaft. One end of the flat steel strip 200 is pulled and For backward transport, the reel 12 continuously transports the flat steel strip backward through its own rotation. In addition, the entire roll of flat steel strip is placed on the steel strip tension unwinding device 10, and the steel strip 200 released by the unwinding device 10 has a certain tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com