High-precision cut-out device and high-precision punching cut-out equipment thereof

A technology of cutting device and cutting equipment, which is applied in the field of mechanical parts processing, can solve problems such as errors and affecting the accuracy of plate strip 1a, and achieve the effects of saving costs, improving drilling efficiency, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

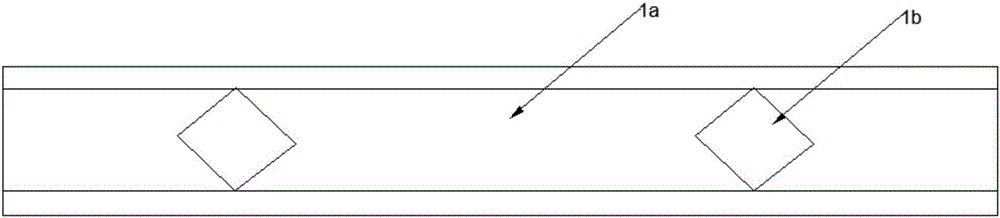

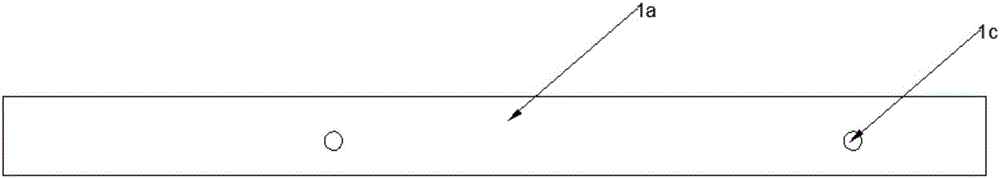

[0029] see figure 2 , The side of the plate strip to be cut is usually provided with a process hole 1c. The present invention makes full use of the positional relationship between the process hole 1c and the punching hole 1b of the sheet material to realize high-precision cutting of the sheet material.

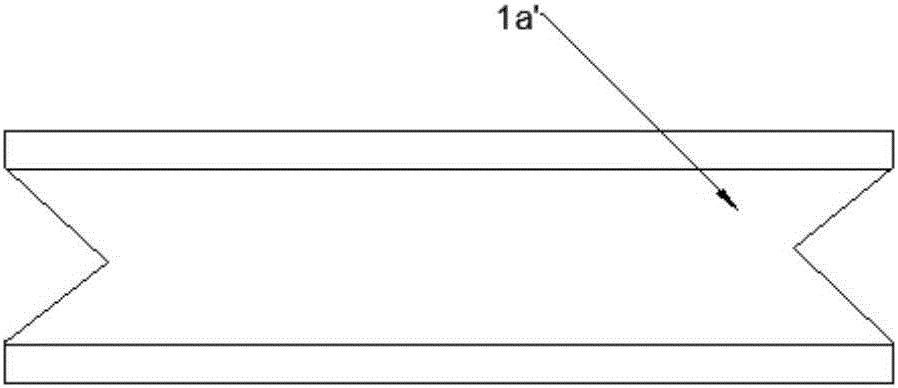

[0030] see Figure 4 , which is a schematic structural diagram of Embodiment 1 of the high-precision cutting device of the present invention. The high-precision cutting device 10 includes a length detection mechanism 11 , a cutting positioning mechanism 12 , a cutting mechanism 13 and a control mechanism. The length detection mechanism 11 is arranged on one side of the plate strip 1a to be conveyed, and is used for detecting the length of the plate strip 1a. The cutting and positioning mechanism 12 is periodically inserted into the process hole 1c of the plate strip 1a for positioning. The cutting mechanism 13 is arranged between the length detection mechanism 11 and the ...

Embodiment 2

[0041] The high-precision cutting device of this embodiment includes a punching device 20 , a cold roll forming machine and a cutting device arranged along the conveying direction of the plate strip 1a. The punching device 20 is used for punching holes on the sheet material strip 1a; the cold roll forming machine continuously bends the sheet material strip material transversely, and bends the sheet material strip material 1 to form a process hole 1c. After the cutting device is positioned according to the process hole 1c, it cuts off the plate strip 1a along the punching hole.

[0042] see Figure 7 , which is a schematic structural view of the punching device in Example 2. The punching device 20 includes a feeding mechanism 21 , a punching mechanism 22 and a punching positioning mechanism 23 arranged in sequence along the conveying direction of the plate strip 1a. The feeding mechanism 21 is used to continuously transport the sheet material strip to the punching mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com