Device and method for automatically measuring quantity and length of cloth

An automatic measurement and cloth technology, applied in the direction of measuring devices, counting mechanisms/items, instruments, etc., can solve the problems of meter counter length deviation, measurement errors, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

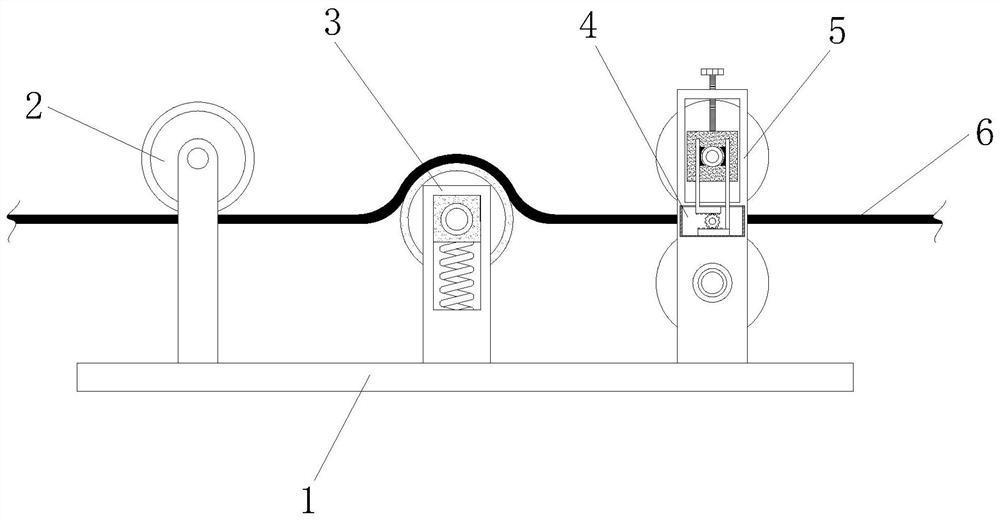

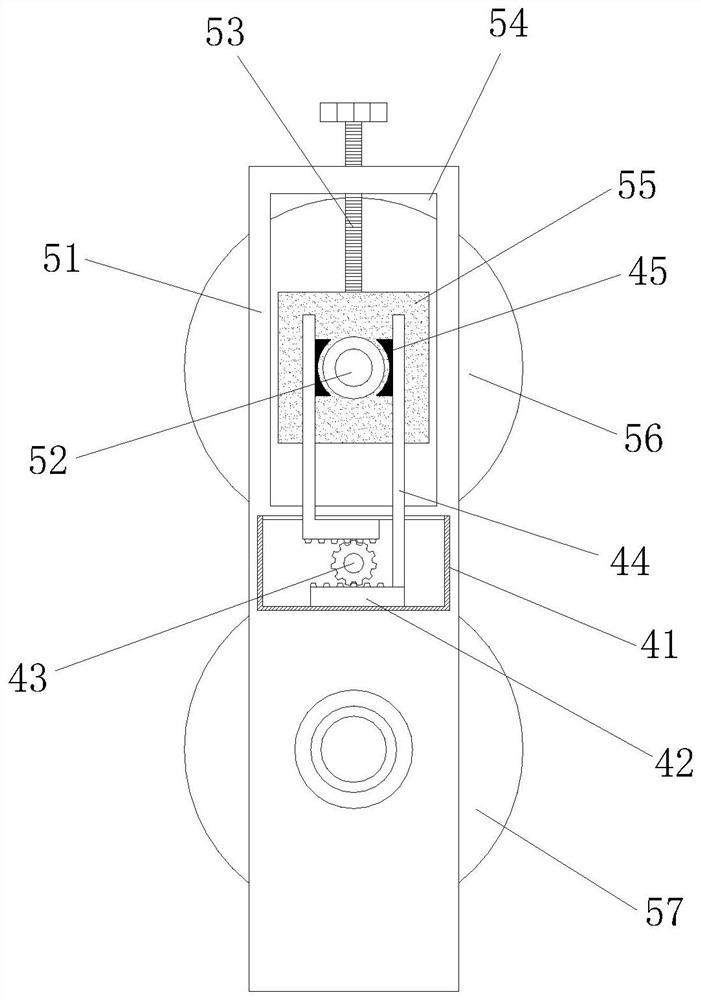

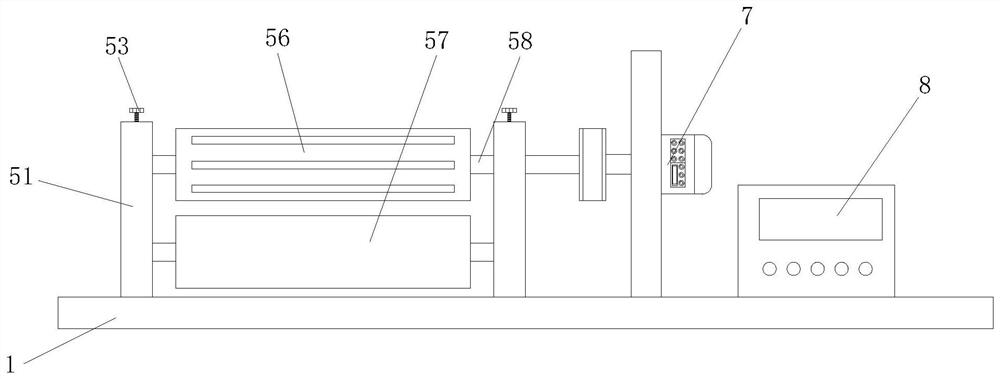

[0034] Please refer to Figure 1 to Figure 4 and Image 6 , the present invention provides a device for automatically measuring the quantity and length of cloth, including a base 1, characterized in that, the base 1 is provided with a traction wheel 2, a tensioning mechanism 3 and a measuring mechanism 5 in sequence from left to right, and the The measuring mechanism 5 includes a connecting frame one 51 oppositely arranged front and back and a first rolling roller 56 and a second rolling roller 57 which are rotatably installed between the connecting frame one 51, and the first rolling roller 56 is connected by a rotating shaft 58 The connecting frame one 51, the rotating shaft 58 at one end of the first rolling roller 56 is connected with a roller meter meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com