Method and apparatus for measuring volume of goaf by using gas concentration difference method

A technology of gas concentration and goaf, applied in the direction of volume measurement instrument/method, measuring device, measuring capacity, etc., can solve the problems of smaller volume of goaf, unsuitable for karst cavity, unable to accurately obtain the volume of goaf, etc. , to achieve the effect of improving budget accuracy, facilitating integration and promotion, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

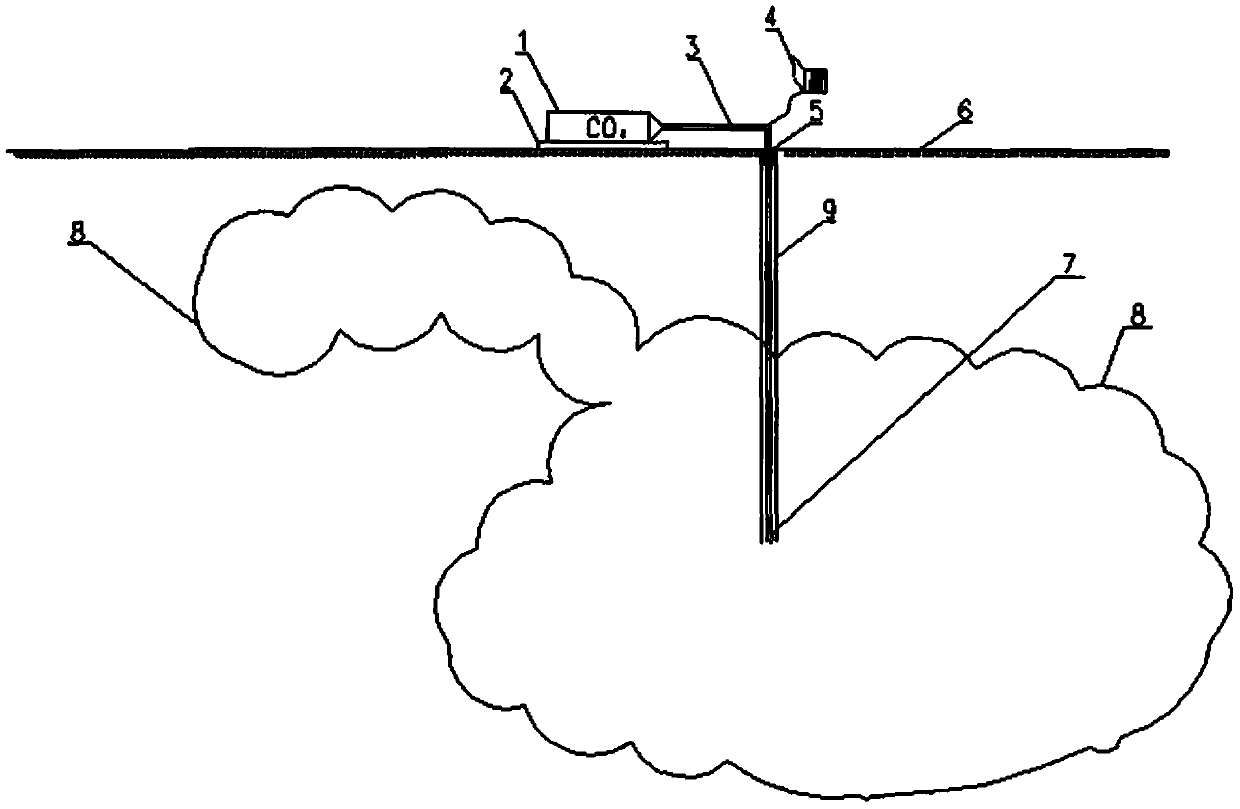

[0056] A method for measuring the volume of a gob by using the gas concentration difference method in this embodiment includes:

[0057] Step 1: After determining the location of the goaf, drill to obtain a borehole connected to the goaf;

[0058] Step 2: Use the concentration detection sensor to measure and obtain the original pre-selected gas concentration value ρ in the goaf 1 ;

[0059] Step 3: Connect the preselected gas storage equipment and inject the preselected gas into the goaf, record the mass Δm of the injected preselected gas and the concentration value ρ of the preselected gas in the goaf at this time 2 ;

[0060] Step 4: According to the formula Calculate the goaf volume V x .

[0061] In specific implementation, the pre-selected gas in this embodiment is CO 2 gas.

[0062] In order to avoid harm to the measurement personnel due to gas leakage, the pre-selected gas in this embodiment is CO 2 gas, and CO 2 Gas is also common in gobs.

[0063] It should...

Embodiment 2

[0073] A device for measuring the volume of a gob by using the gas concentration difference method in this embodiment includes:

[0074] A concentration sensor, which is arranged in the goaf, is used to detect the pre-selected gas concentration value in the goaf;

[0075] A communication pipeline, which is used to communicate with preselected gas storage equipment and inject preselected gas into the goaf;

[0076] Gravimetric equipment for obtaining the mass Δm of the preselected gas injected into the goaf;

[0077] Controller, configured as:

[0078] Receive the concentration detection sensor to measure the original pre-selected gas concentration value ρ in the goaf 1 ;

[0079] The concentration value ρ of the preselected gas in the goaf when the preselected gas mass Δm is injected into the goaf 2 ;

[0080] According to the formula Calculate the goaf volume V x .

Embodiment approach

[0081] As an embodiment, the preselected gas is CO 2 gas.

[0082] In order to avoid harm to the measurement personnel due to gas leakage, the pre-selected gas in this embodiment is CO 2 gas, and CO 2 Gas is also common in gobs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com