Patents

Literature

32results about How to "Mature equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tobacco stem shred preparation method

A tobacco stem shred preparation method includes steps of pretreatment of tobacco stems, microwave expansion of tobacco stems, moisture regaining of expanded tobacco stems, tobacco stem shredding, stem shred screening and winnowing, stem shred feeding, second tobacco shred expansion, stem shred flavoring and the like. The prepared tobacco stem shreds are similar to tobacco shreds in appearance and shape, have the advantages of high filling performance, soft flavor and low stimulation in sensing quality and the like and are good in suitability for smoke.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

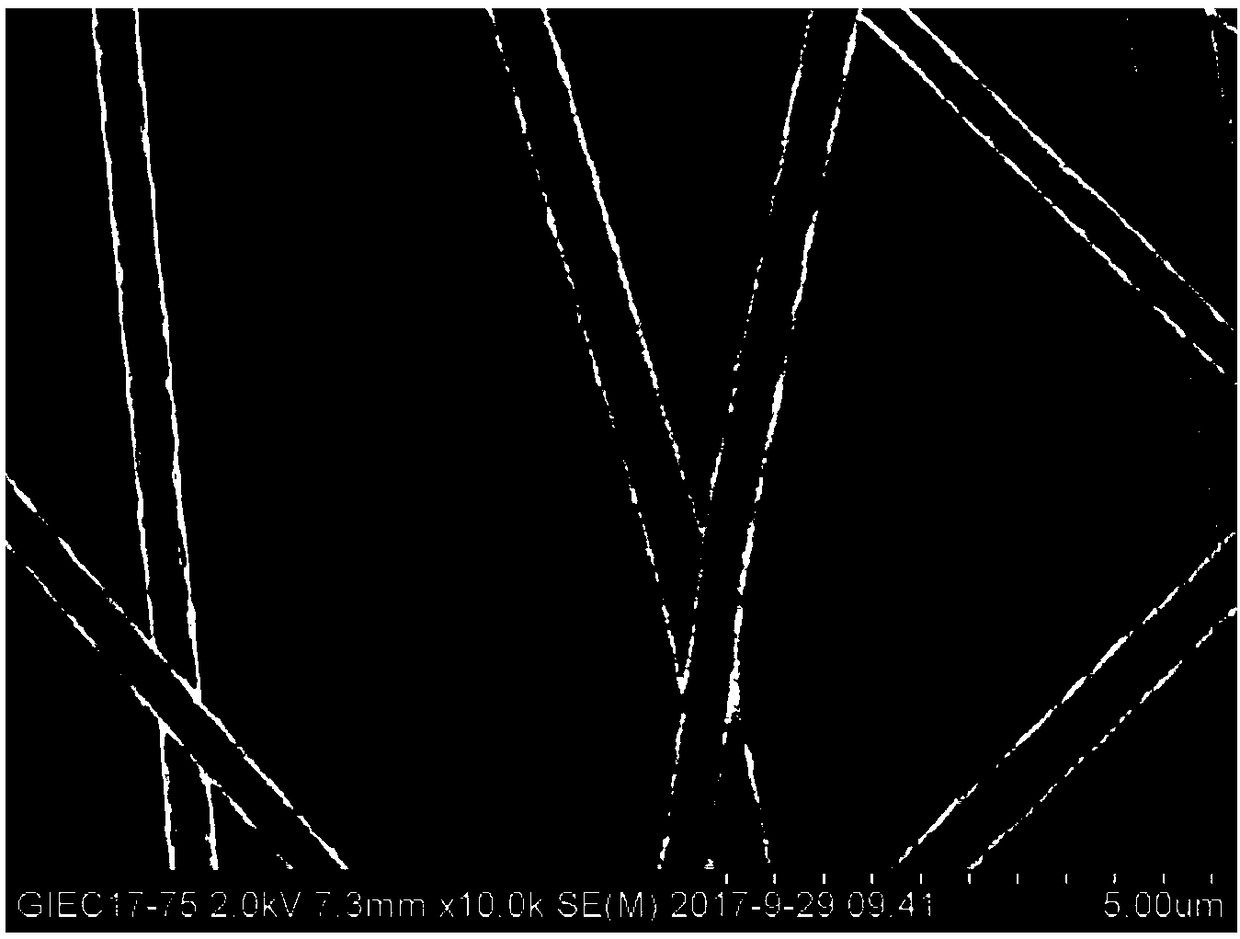

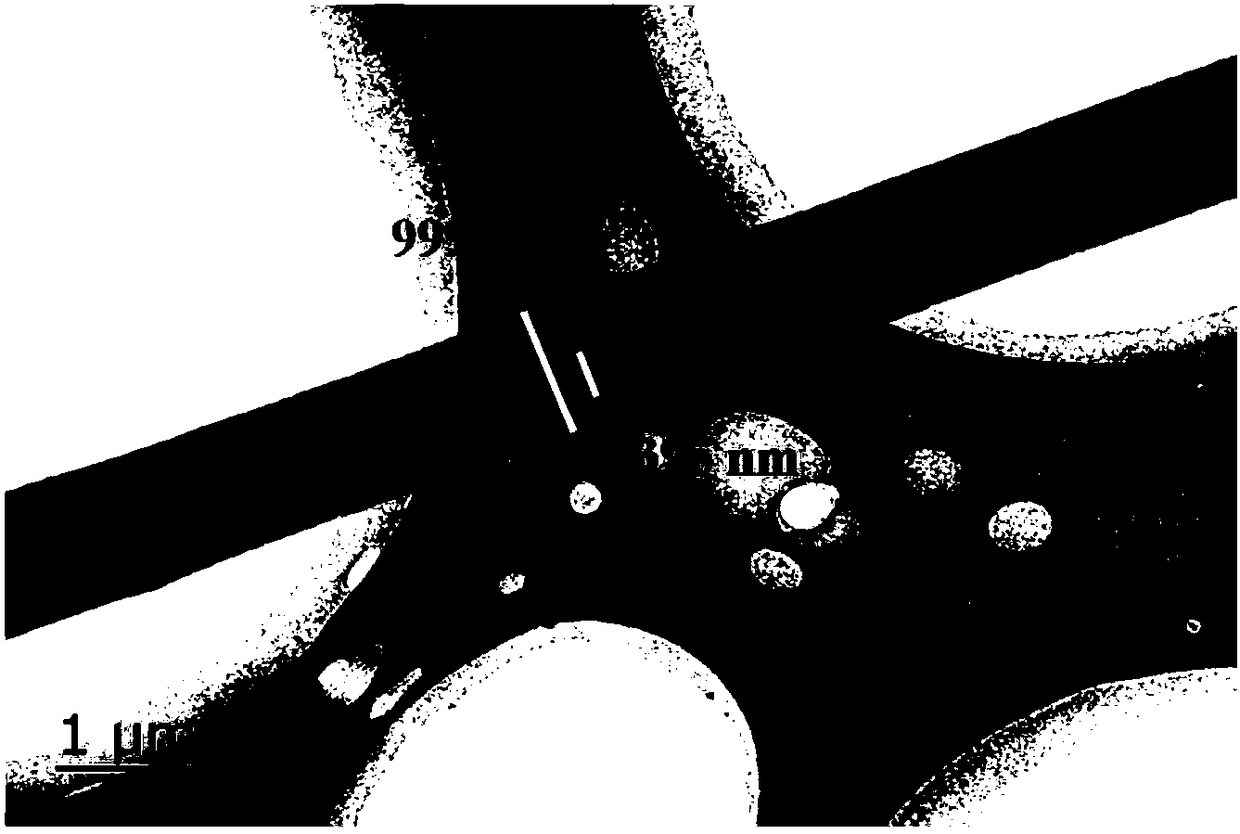

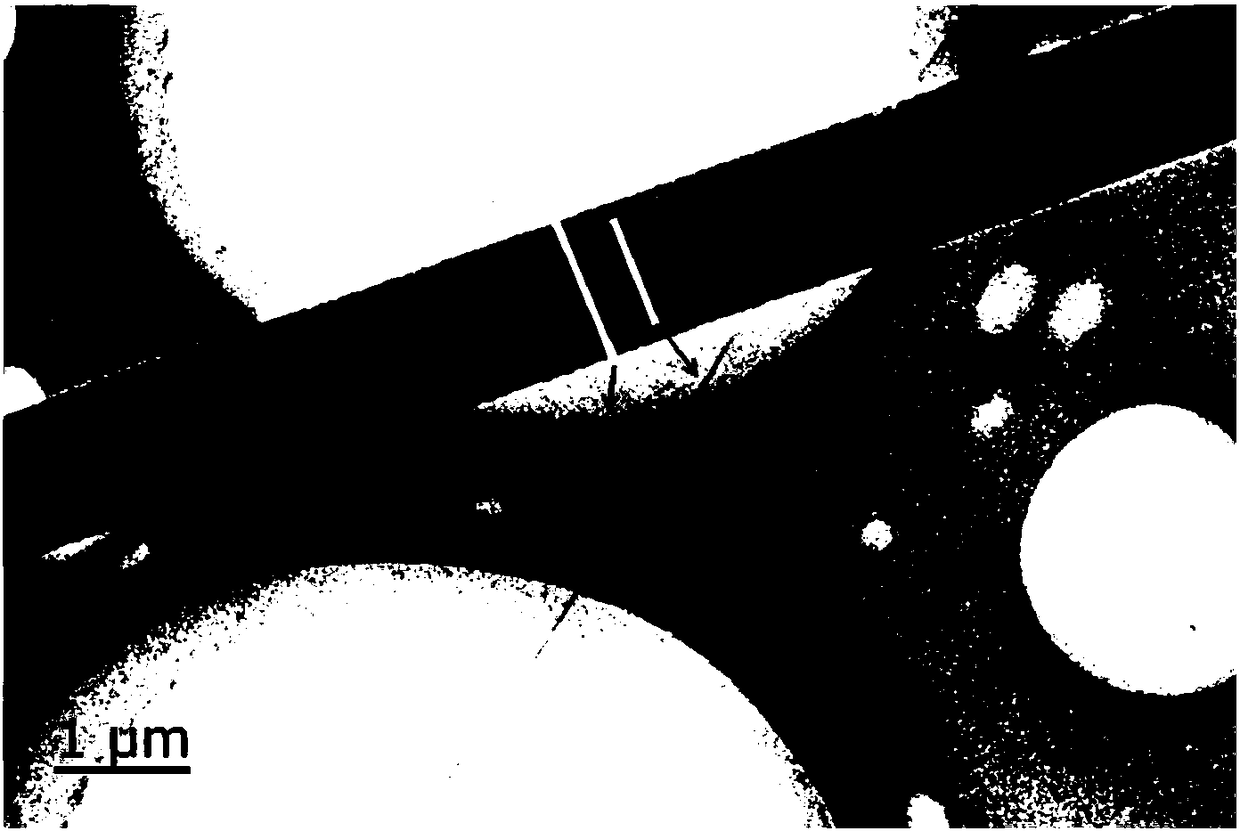

Method for preparing phase-change heat-storage fiber membrane with core-shell structure by utilizing coaxial electrospinning technology

InactiveCN108570766ASolving Phase Change Process LeakageEasy to prepareFilament/thread formingConjugated synthetic polymer artificial filamentsSolventChemistry

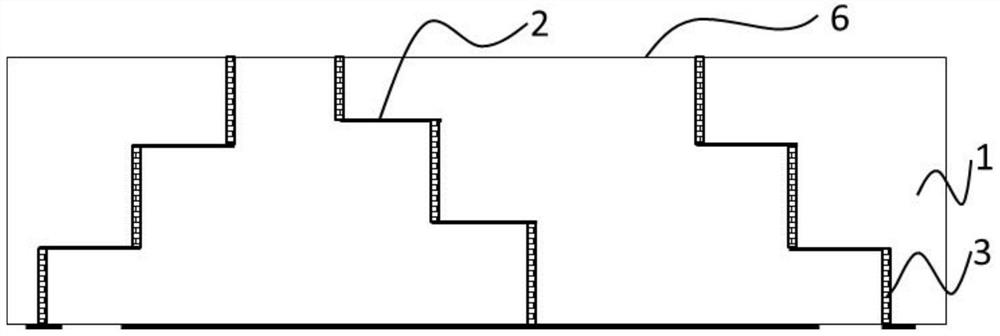

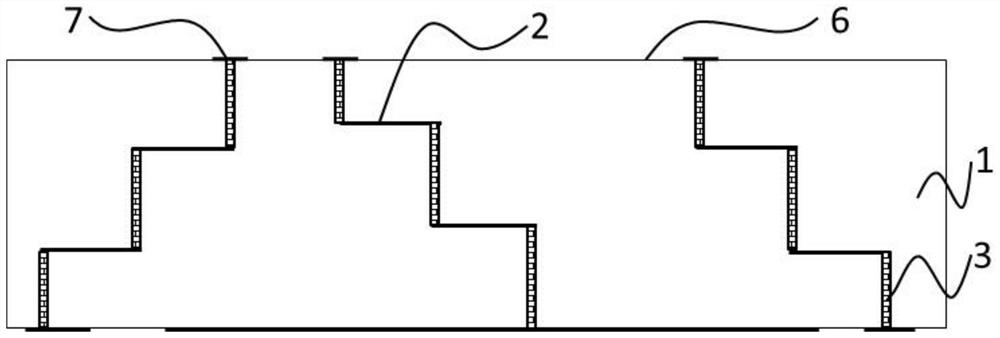

The invention provides a method for preparing a phase-change heat-storage fiber membrane with a core-shell structure by utilizing a coaxial electrospinning technology. The method comprises the following steps: (1) adding a phase change material into a first solvent, and stirring until completely dissolving to obtain a core layer solution; (2) adding a polymer material into a second solvent, and stirring until completely dissolving to obtain a shell layer solution; (3) injecting the core layer solution obtained in the step (1) and the shell layer solution obtained in the step (2) into two solution channels of a coaxial electrospinning device correspondingly, and adjusting coaxial electrospinning parameters for electrospinning to obtain the phase-change heat-storage fiber membrane with the core-shell structure. The preparation method of the phase-change heat-storage fiber membrane, proposed by the invention, is simple; equipment and the technology are mature; the used raw materials are non-toxic, harmless and wide in source, so that the production cost is low; and the phase-change heat-storage fiber membrane can be used for fields of energy-saving building materials, phase-change heat-storage systems, functional fabrics and the like, thereby providing a new idea for development of phase-change heat-storage materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

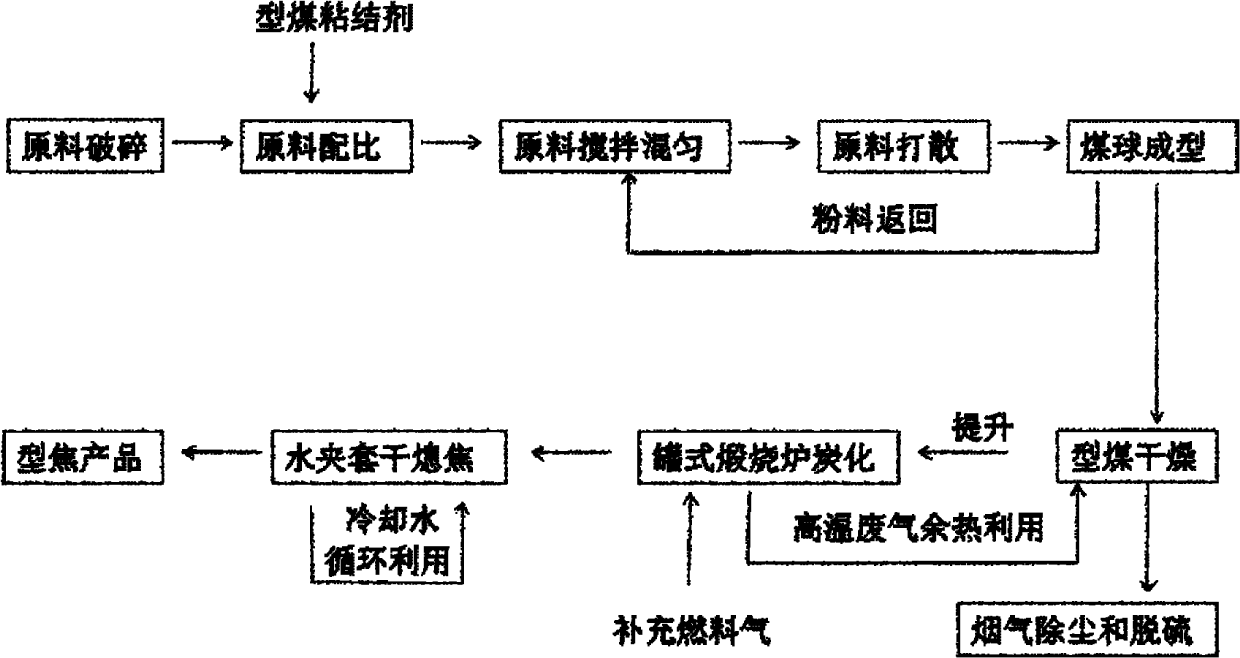

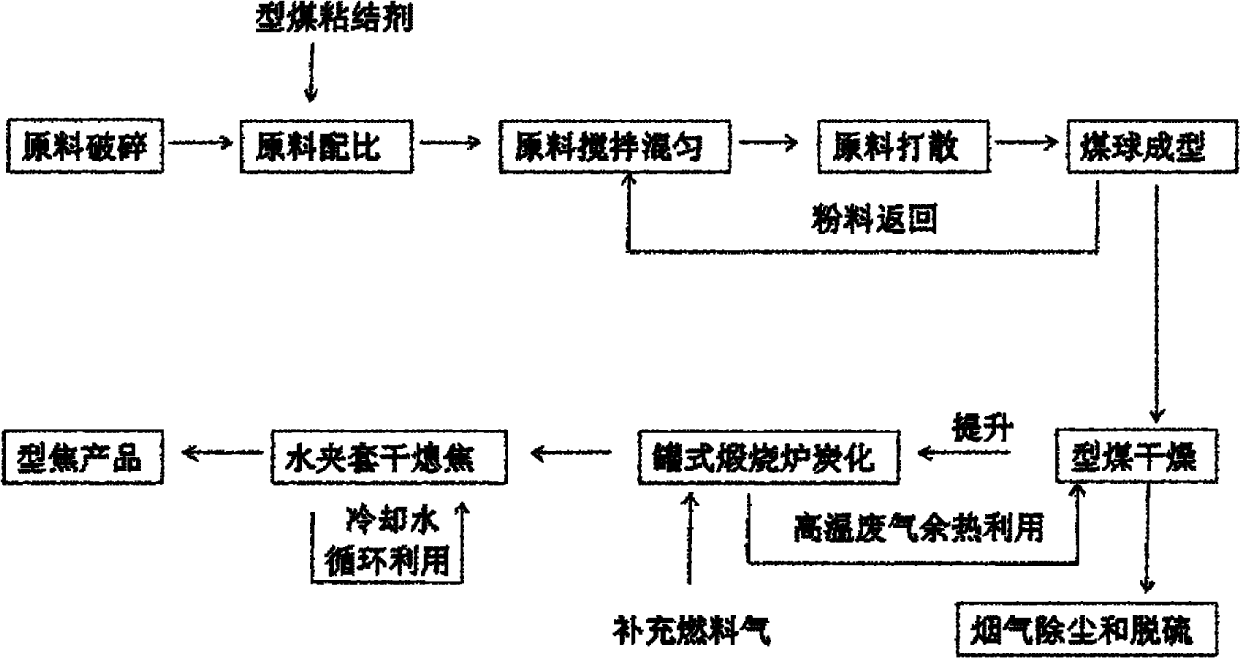

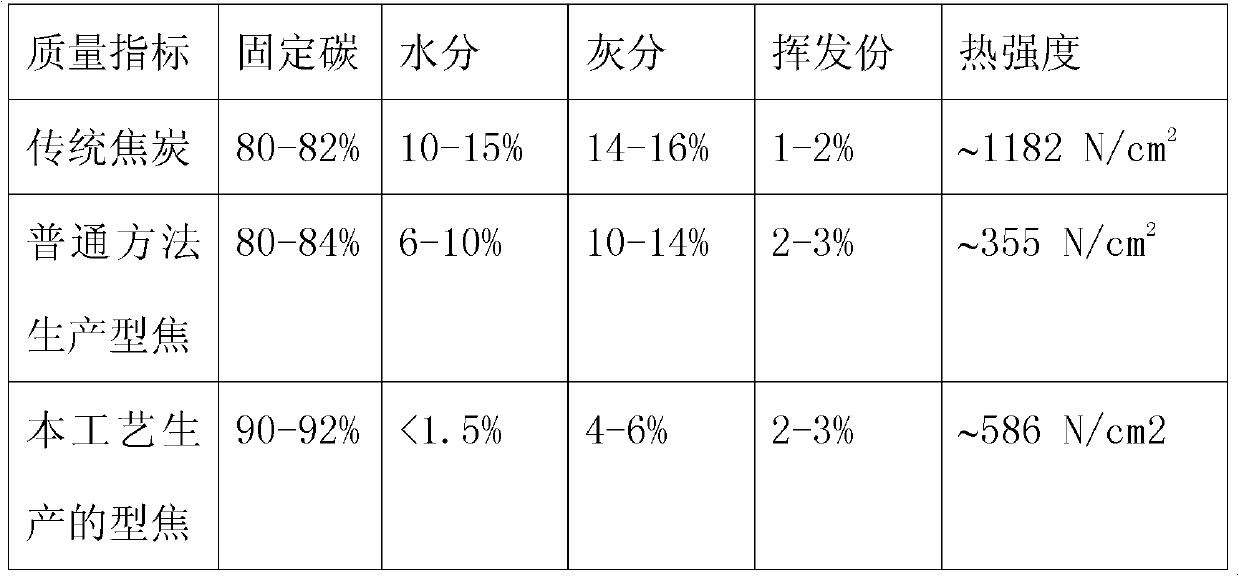

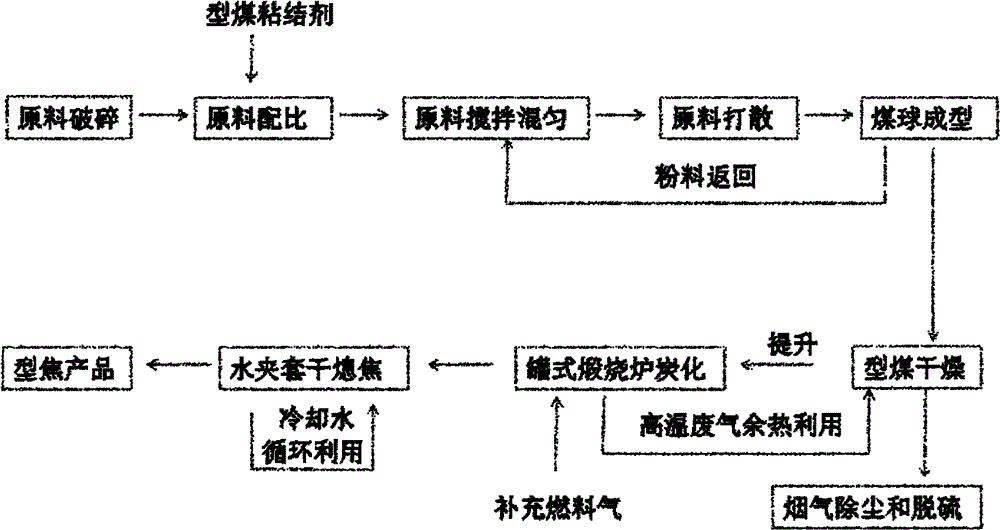

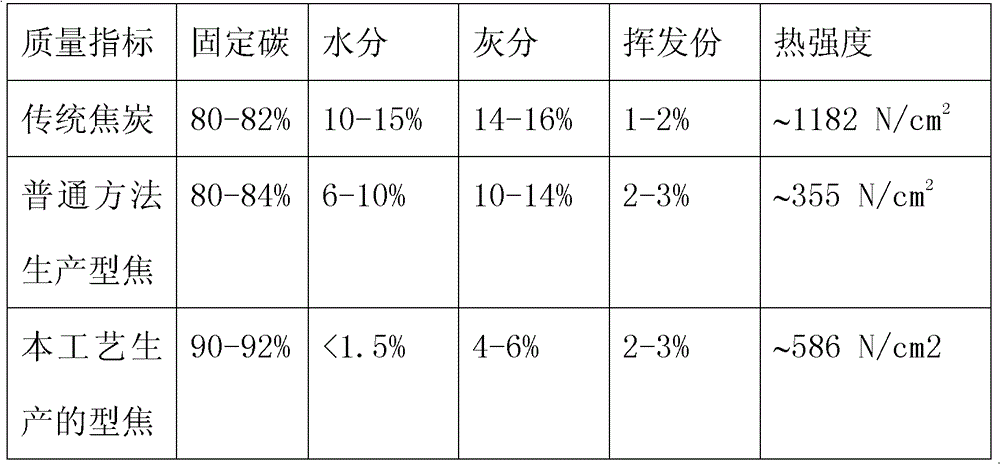

Production method of formed coke

ActiveCN102079982AIncrease the drying processHigh calorific valueCoke quenchingEnergy inputEngineeringWater jacket

The invention discloses a production method of formed coke. In the method, the working procedure of drying formed coke is added, thus the carbonization time can be shortened, the calorific value of dry distillation gas can be increased, and the large-scale production of formed coke can be ensured; an external combustion type carbonization furnace is used in the carbonization process, the carbonization equipment has long flue stroke, the residence time of flue gas is long and the thermal efficiency is high; the quantity of heat can be adjusted to ensure the carbonization quality of the formed coke; the integration of carbonization and dry quenching can be realized, energy-saving analysis is performed on the energy requirement and supply of the carbonization process and a specific energy-saving scheme is provided; a specific temperature control scheme of the carbonization process is provided particularly for the carbonization of formed coke prepared from calcium carbide; and a novel water jacket is used for dry quenching, thus the water content of the formed coke product can be reduced, the water pollution can be prevented, the energy can be saved and the strength of formed coke canbe increased. The formed coke produced by the method meets the quality requirements, the operating cost is low, the floor space is small, the investment is less, the technology and equipment are mature and the industrial and large-scale production can be realized.

Owner:YIBIN TIANYUAN GRP CO LTD

Method for inter-regional direct taxi calling

InactiveCN103177573AImprove operational efficiencyAlleviate the social problem of difficulty in taking a taxiRoad vehicles traffic controlInformation processingInformation transmission

The invention belongs to the technical field of information transmission, and relates to a method for inter-regional direct taxi calling. The method includes that a taxi requester presses an operating button to send a taxi request, taxi request information is displayed in an information display unit and passes an encoding processing module, and then information sent by a microprocessor is inputted and transmitted via a wireless transmission protocol and a wireless network system to search a target taxi; after the wireless network system obtains the request information through a mobile antenna and a second information receiving module, specific location of the request information is obtained via an information processing module; a driver operating button sends out service response information; the service response information is processed by the information processing module prior to sending of response information; the fixed request location obtains basic information of a response taxi via the encoding processing module; and after the taxi arrives, the requester operates the button to cancel the taxi request. The method is simple in technical process, safe and reliable in principle, mature in equipment and technology, convenient and flexible for mounting and use, high in taxi running efficiency and good in economic benefit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

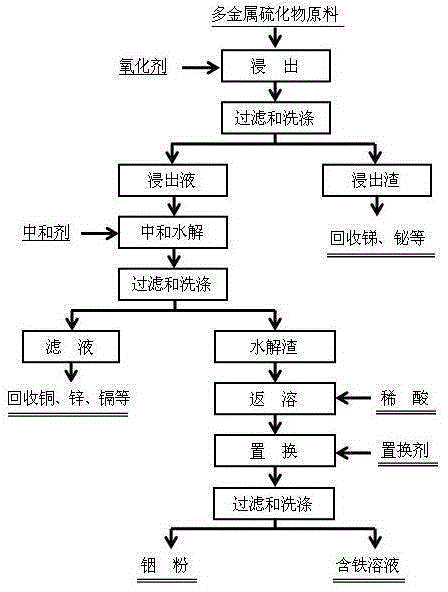

Method for preparing sponge indium from polymetallic sulfide material

The invention discloses a method for preparing sponge indium from a polymetallic sulfide material. The method comprises the steps that the polymetallic sulfide material is mixed with an oxidizer and water, poured into a sealed titanium reaction kettle to be leached and filtered and washed, so that leaching liquid and leaching residue are obtained; the leaching liquid mainly comprises lead, copper, indium, iron, cadmium, silver and the like, and the leaching residue is used for extraction of nonferrous metal elements such as antimony and bismuth; the leaching liquid is added with a neutralizer and filtered and washed, so that a hydroxide mixed precipitation containing the indium and the iron and filtrate containing the copper, the lead, zinc, the silver and other elements are obtained; the hydroxide mixed precipitation containing the indium and the iron is added with dilute acid to be adjusted and is subjected to re-dissolution; and the re-dissolution solution is added with a displacer to enable ferric ions to be reduced to ferrous iron and trivalent indium ion reduction indium powder, after filtering and washing are conducted, filtrate containing ferrous ions and the like and sponge indium powder are obtained, and the sponge indium powder is obtained after drying is conducted. The method for preparing the sponge indium from the polymetallic sulfide material has the advantages of being simple in process, low in processing cost, high in indium yield, easy to industrialize and the like and can efficiently process the polymetallic sulfide material containing the indium.

Owner:KUNMING METALLURGY COLLEGE

Double-side aluminum-coating steel composite material and preparation method thereof

InactiveCN108045020AAdjustable thicknessCovering ratio is easy to controlLamination ancillary operationsLaminationAlloyUltimate tensile strength

The invention relates to a double-side aluminum-coating steel composite material and a preparation method thereof. The double-side aluminum-coating steel composite material is formed by rolling a baselayer and two coating layers separately positioned at two sides of the base layer and then carrying out heat treatment at 200-400 DEG C, wherein the base layer is a stainless steel layer, and each coating layer is an aluminum alloy layer. The bonding strength of the base layer and the coating layers of the double-side aluminum-coating steel-aluminum composite material is high and reaches 32 N / mm,and delamination does not occur easily.

Owner:YINBANG CLAD MATERIAL

Efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry and its preparation method

ActiveCN102511503BWith synergistic antibacterial and antifungal propertiesSynergisticBiocideFungicidesNano al2o3Slurry

Relateing to the field of antibacterial materials, the invention specifically provides an efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry obtained through compounding nano-magnesium oxide and other nano-inorganic materials and its preparation method. The nano-powder slurry takes nano-magnesium oxide as the main body, which is then compounded with one or more inorganic materials of nano-zinc oxide, nano-titanium oxide, nano-copper oxide, nano-cuprous oxide, nano-silver oxide, nano-zinc sulfide, nano-zirconium oxide, nano-yttrium oxide, nano-alumina, and nano-calcium oxide so as to form the nano-powder slurry, which comprises, by weight percent: 0.1-40% of nano-magnesium oxide, 0.01-40% of other inorganic materials, 0.5-12% of a polymeric dispersant, and the balance a solvent. In the method, a nano-inorganic material enters a solution composed of the polymeric dispersant and the solvent by means of high speed dispersion according to a predetermined proportion, and after ball milling, the composite nano-powder slurry can be obtained. The composite nano-powder slurry can be applied in antibacterial coatings, deodorants, textiles, paper products, plastics, rubbers, water treatment agents, ship protective agents, cosmetics and other aspects.

Owner:广东腐蚀科学与技术创新研究院

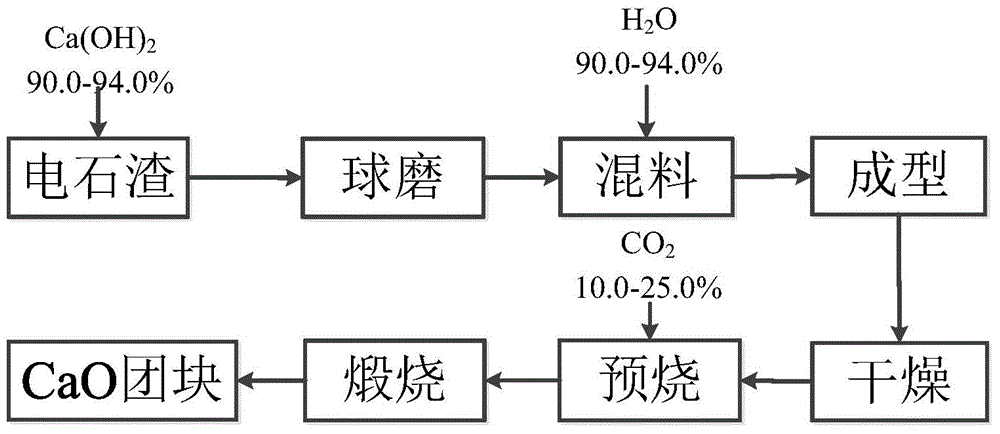

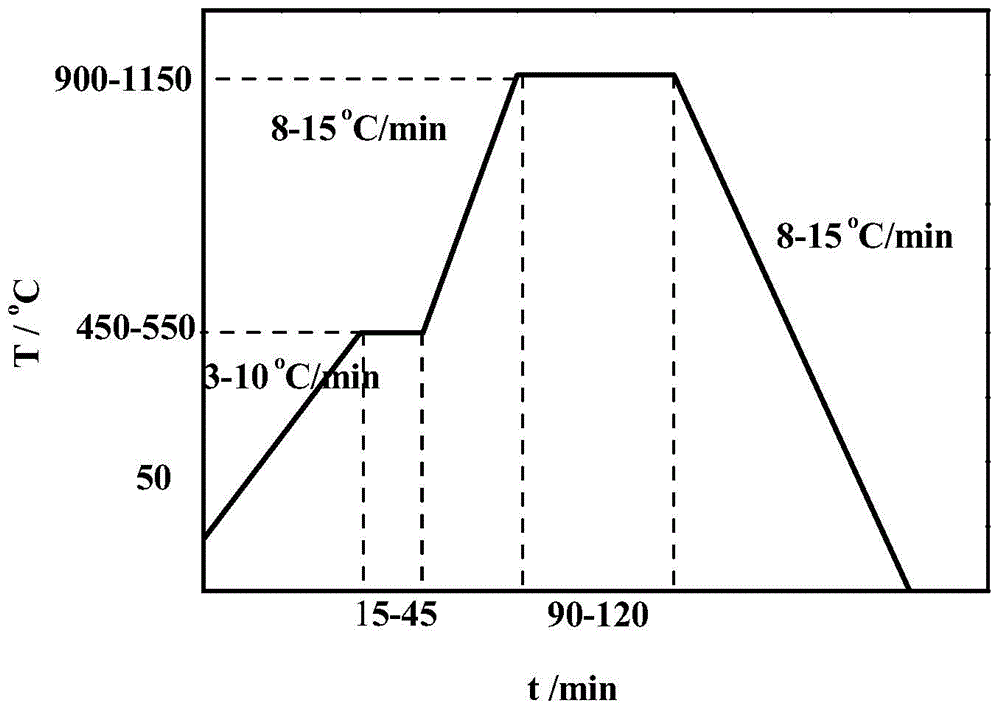

High-thermal-shock-resistance calcium oxide pellet and preparation method thereof

InactiveCN103951290ASimple operation processMature equipmentSolid waste disposalRotary kilnAtmosphere

The invention discloses a high-thermal-shock-resistance calcium oxide pellet and a preparation method thereof. The preparation method comprises the following steps: ball-milling carbide slag powder with 91.0-94.0% of Ca(OH)2 until the particle size is 60.0-150.0 mu m; adding 5.0-15.0% of H2O as a binder into the ball-milled powder, and uniformly mixing the obtained product; carrying out compression molding on the uniformly mixed powder at a molding pressure of 100.0-350.0 kgf / cm<2>, and then carrying out pressure maintaining for 0.5-3.0 min; drying the obtained product for 10.0-24.0 h; calcining the dried blank to 450.0-650.0 DEG C under an atmosphere with a CO2 concentration of 10.0-25.0%, and maintaining a constant temperature for 15.0-45.0 min; and calcining the obtained product for 90.0-120.0 min at a temperature of 900.0-1150.0 DEG C, and then carrying out furnace cooling. The strength of the calcium oxide pellet prepared according to the invention is reduced by 6.0-25.0% under the conditions that the difference between the temperature of the calcium oxide pellet and the room temperature is 500.0-1100.0 DEG C and the number of hot and cold cycles is 5.0-10.0. The method disclosed by the invention improves the thermal shock resistance of calcium oxide pellets in two stages of an application process; after being calcining in a rotary kiln, the calcium oxide pellet is subjected to quick cooling impact from 1100-1200 DEG C to 100-200 DEG C; and when being put into a calcium carbide furnace, the calcium oxide pellet is subjected to quick heating impact at a temperature of 1000.0 DEG C. Meanwhile, according to the invention, carbide slag is efficiently dealt, therefore, high environmental and economic benefits are obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Dimeit ironmaking method directly using coal for ironmaking and Dimeit furnace

The invention discloses a dimeth iron making method for iron making by directly using coal, wherein an iron making furnace used by the method is a dimeth furnace; one path leading out coal gas passes through a gas dust collector, a gas pressure regulator, a gas removal CO2 device and a gas temperature regulator in turn, returns to the dimeth furnace and supplies a gas reducer for the dimeth furance, and the other path leading out the coal gas is supplied for a user; the cross section of the dimeth furnace is a circular or polygonous shaft furnace, and a cooler and a fire-retardant internal lining are arranged inside a furnace shell; more than two layers of furnace grills are arranged inside the dimeth furnace, and the inside of the dimeth furance is divided into three main spaces, namely a direct reducing chamber, a gas mixing chamber and a fusing and reducing chamber from the top down; and common oxygen supply blast tuyeres or common reducing and combustion-supporting raw material blowing openings or common special blowing openings are distributed on the circumference of the furnace on the lower part of the dimeth furnace. The method and equipment are suitable for the condition of mill coal resources and completely get rid of the dependency of iron making on coke.

Owner:吴兰

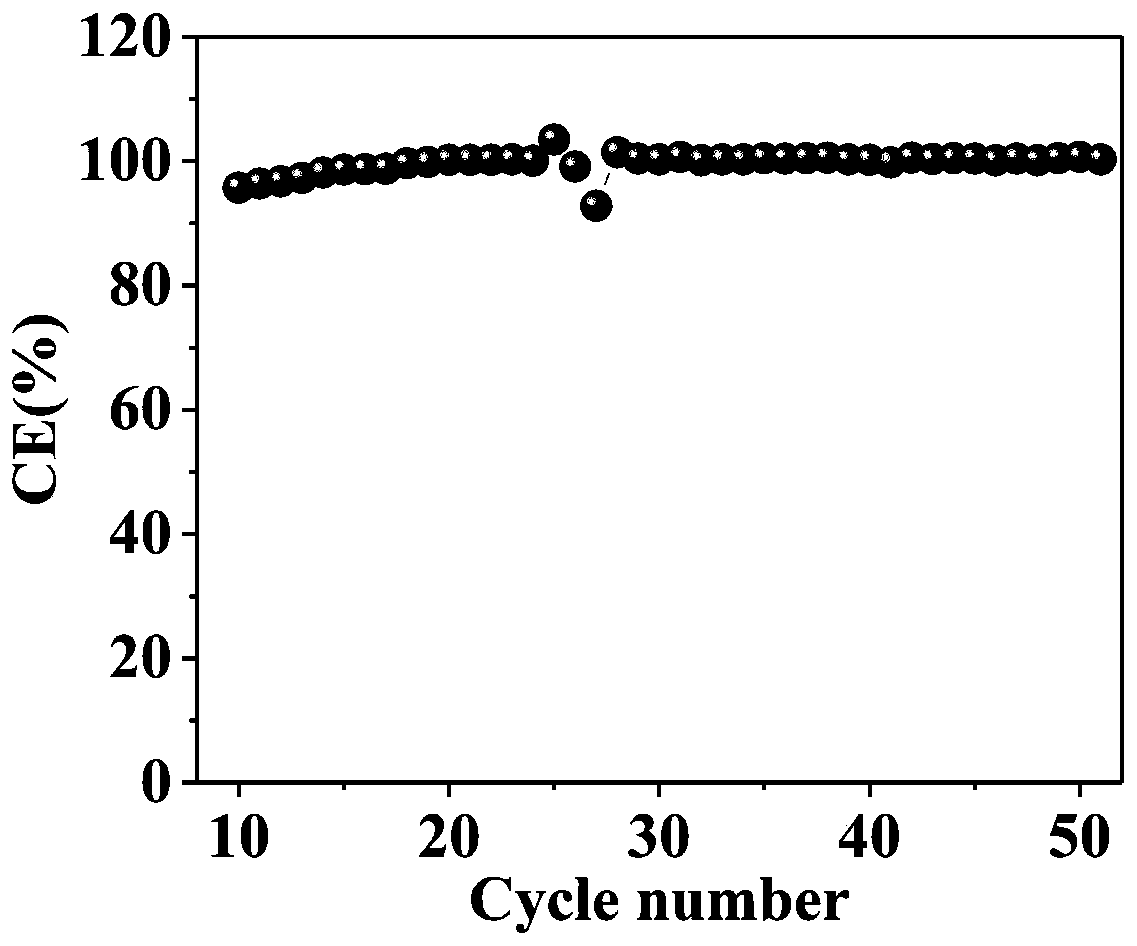

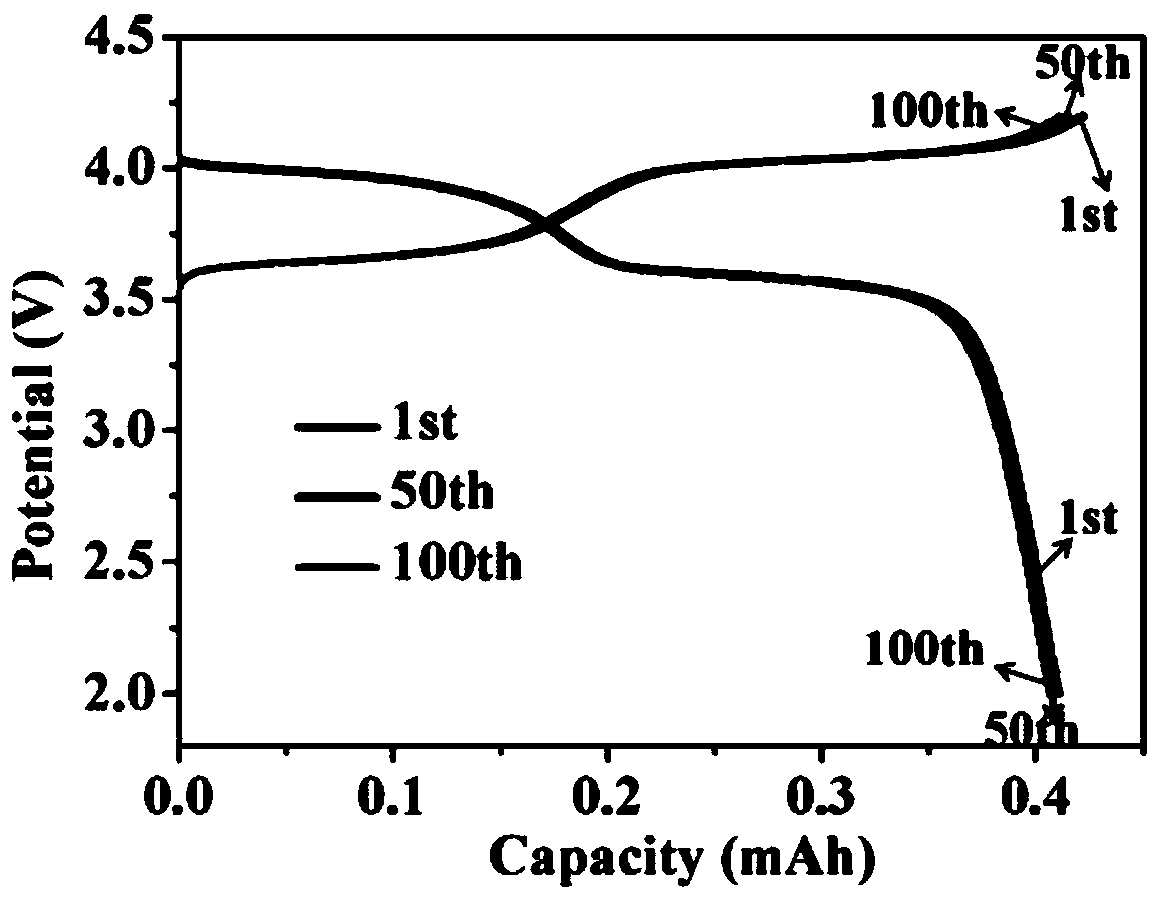

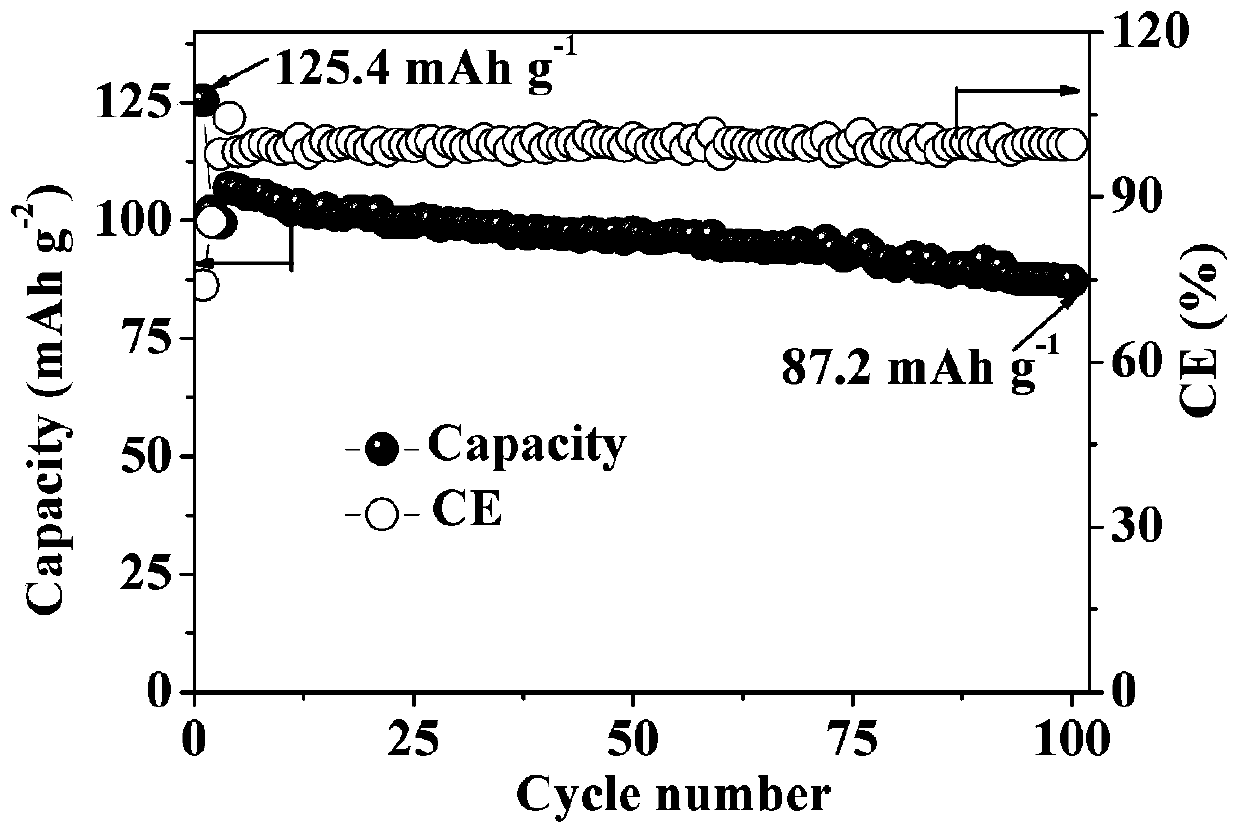

Tin-based negative electrode sodium ion secondary battery

InactiveCN110212238AEasy to makeMature equipmentCell electrodesSecondary cellsMetal foilMechanical property

The invention provides a tin-based negative electrode sodium ion secondary battery, which comprises a tin-based negative electrode and a sodium ion positive electrode, wherein the tin-based negative electrode is a tin-based metal foil. Due to direct use of the tin-based metal foil as the negative electrode material of the sodium ion secondary battery, tedious slurrying, coating and drying processes of the tin powder negative electrode are saved; and meanwhile, due to excellent electrical conductivity and mechanical properties of the tin-based metal foil, the tin-based metal foil can be used asa self-supporting electrode directly without a binding agent and a conductive agent, thereby reducing harm of an organic solvent to environment in the preparation process of a battery electrode sheet, and meanwhile, improving energy density of a battery. The provided tin-based negative electrode sodium ion secondary battery is easy to prepare; and the required industrial technology and equipmentare mature and easy to promote.

Owner:TONGJI UNIV

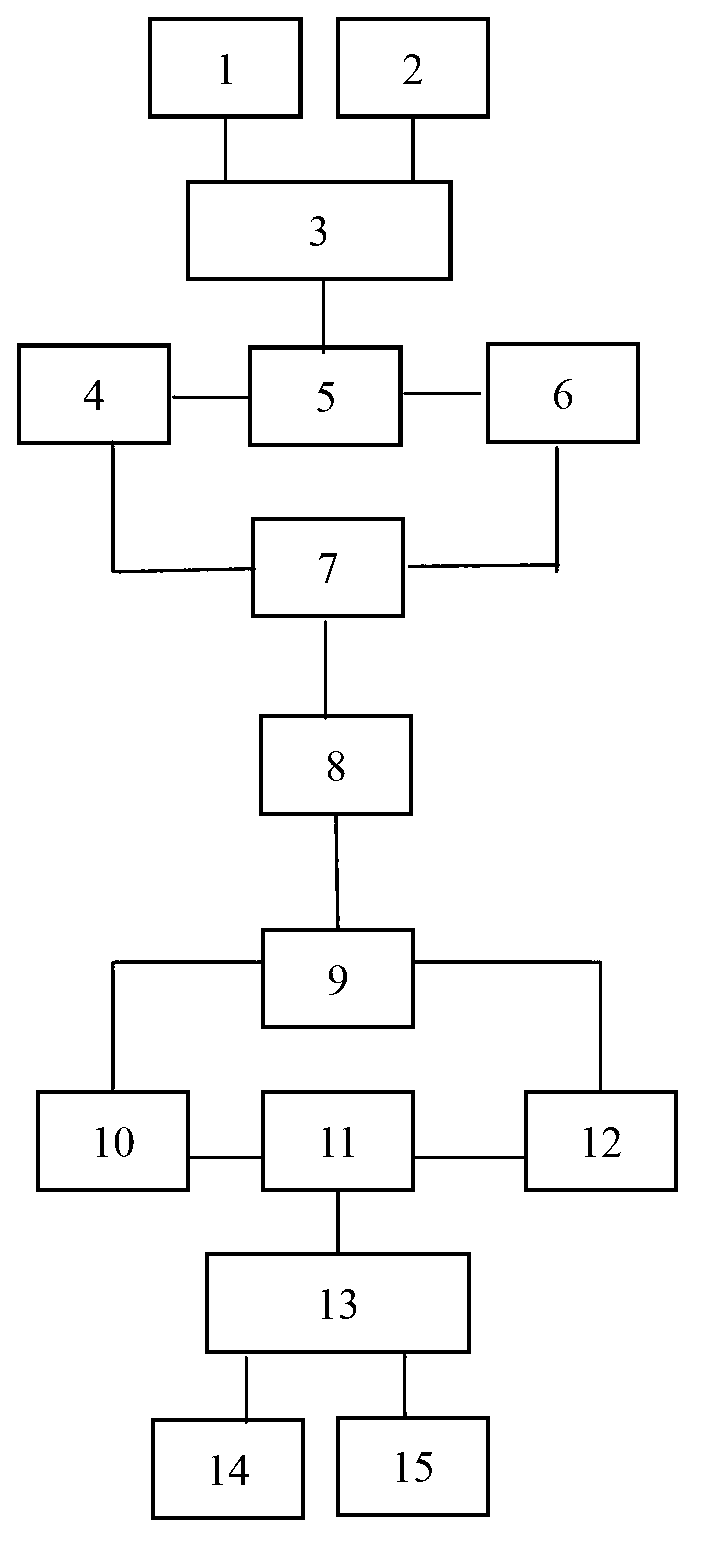

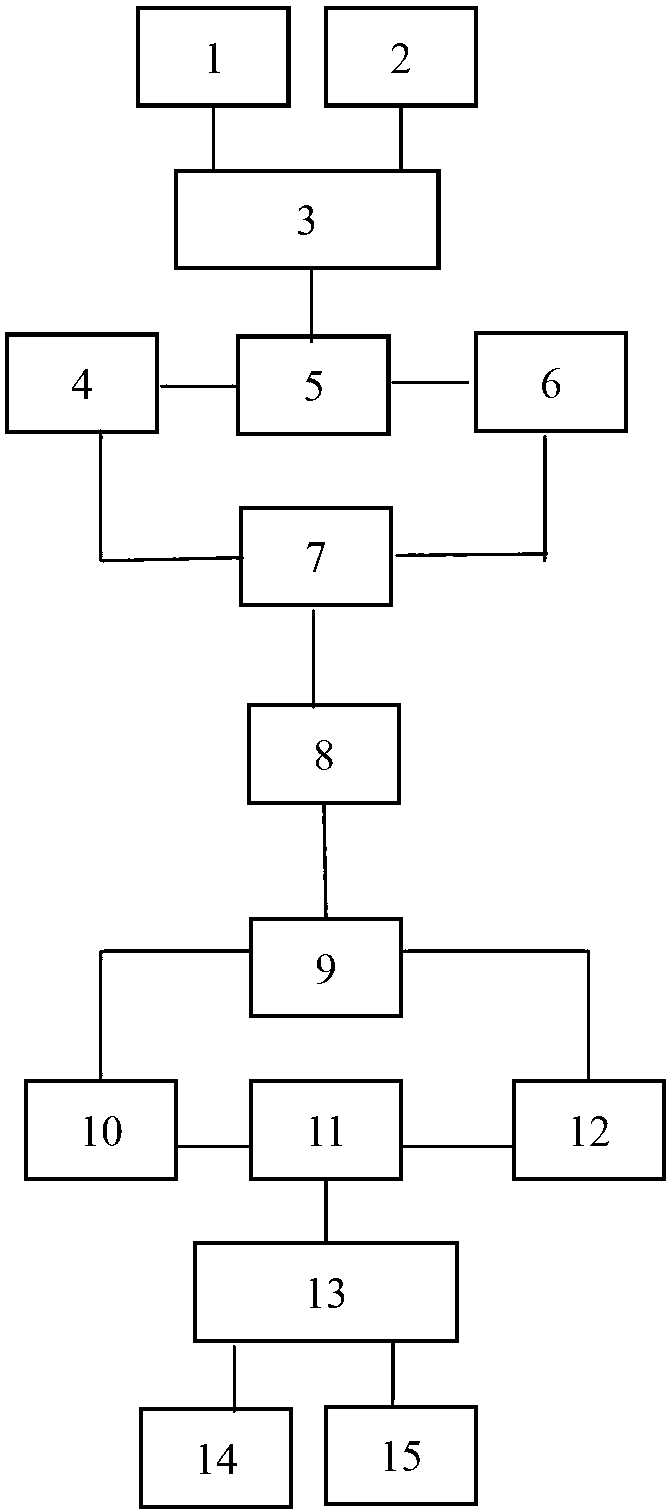

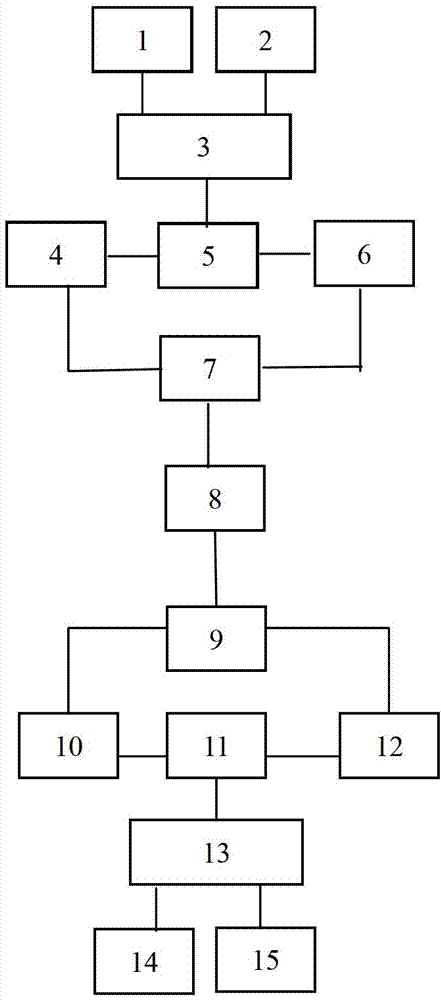

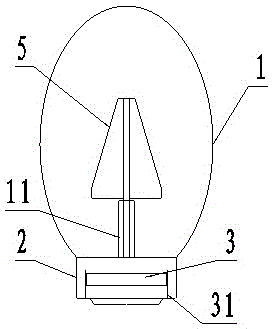

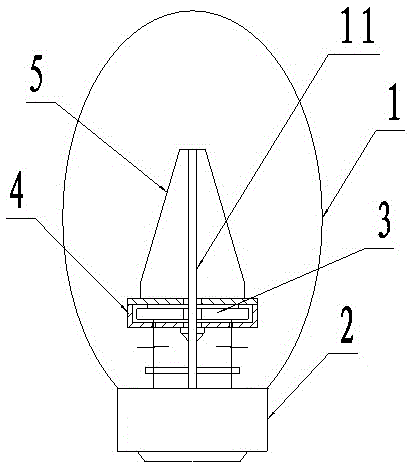

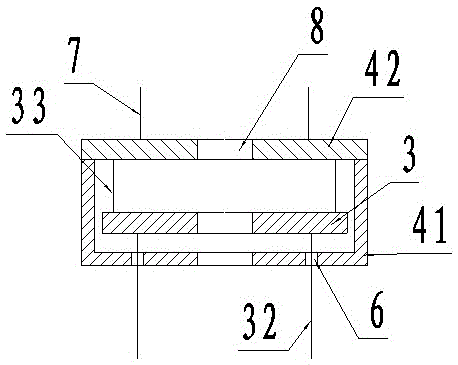

Device for inter-regional direct taxi calling

InactiveCN103177574ATaxi echo realizationImprove operational efficiencyRoad vehicles traffic controlElectricityInformation processing

The invention belongs to the technical field of information transmission, and relates to a device for inter-regional direct taxi calling. An on-board information receiving unit is fixedly mounted in a taxi and comprises an operating button, an encoding processing module, an information receiving module, an information sending module, a microprocessor, an information display module and a mobile antenna, a ground fixed call unit comprises a second microprocessor, an information processing module, a second information sending module, a second information receiving module, an information display module, a button and a fixed antenna, and the on-board information receiving unit is in electric information communication with the ground fixed call unit by the aid of a wireless network system. The device is simple in technical process, safe and reliable in principle, mature in equipment and technology, convenient and flexible for mounting and use, high in taxi running efficiency and good in economic benefit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

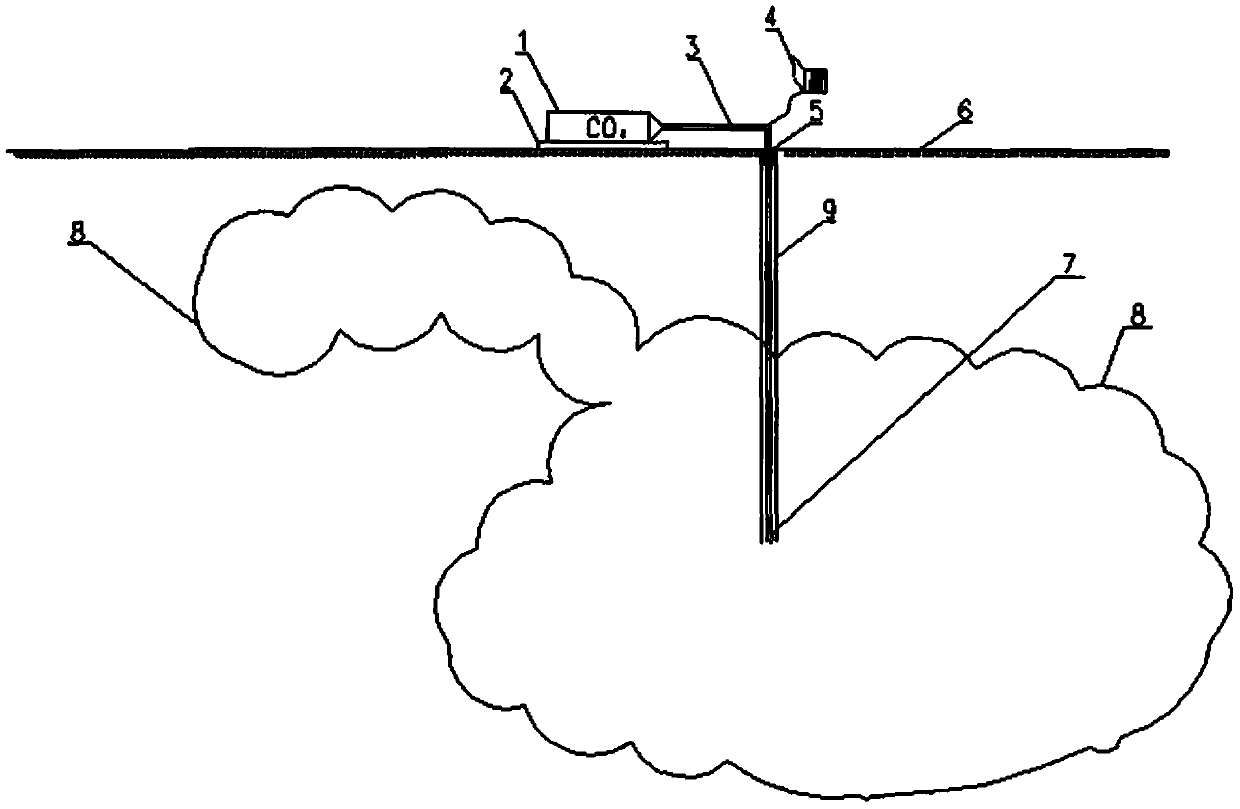

Method and apparatus for measuring volume of goaf by using gas concentration difference method

PendingCN110207780AThe principle is simpleMature equipmentContainer/cavity capacity measurementDrill holeEnvironmental geology

The disclosure provides a method and apparatus for measuring the volume of a goaf by using a gas concentration difference method. The method comprises: after determination of a goaf position, carryingout drilling to obtain a drill hole communicated with the goaf; carrying out measurement by using a concentration detecting sensor to obtain an originally preselected gas concentration value rho1; communicating a preselected gas storage device, injecting preselected gas into the goaf, and recording the mass deltam of the injected preselected gas and a concentration value pho2 of the preselected gas in the goaf at the time; and according to a formula, calculating the volume Vx of the goaf. The volume of the goaf is measured by using the gas concentration difference method; and the volume can be obtained accurately on the premise that the specific shape of the goaf is not considered, so that the accurate data are provided for backfilling of the goaf.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队

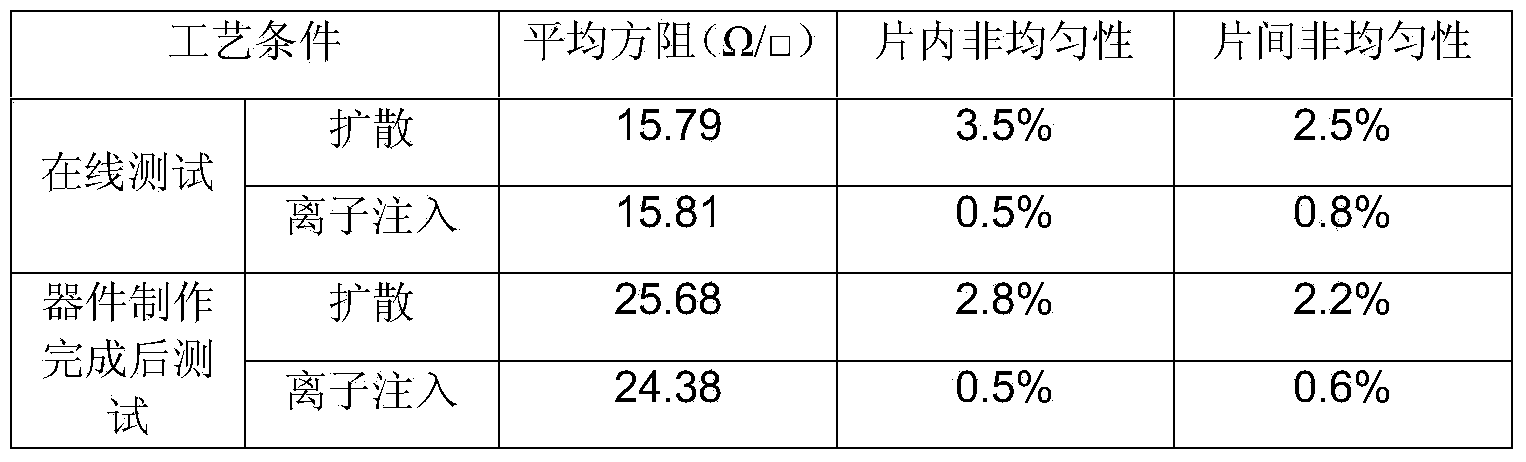

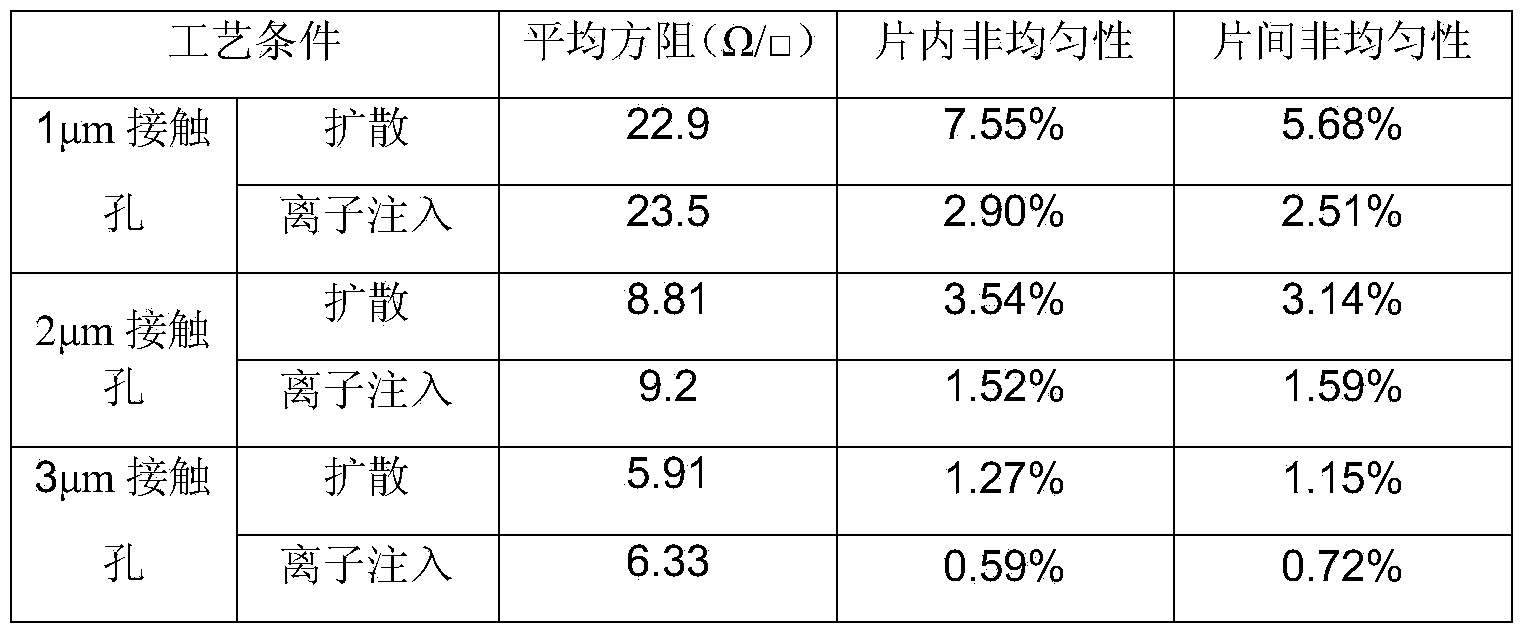

Application of ion implantation technology in CCD fabrication and CCD fabrication technology

InactiveCN103400752AControl UniformityReduce non-uniformitySemiconductor/solid-state device manufacturingPolysilicon gateIon implantation

The invention discloses application of ion implantation technology in CCD fabrication. The ion implantation technology is a conventional ion implantation doping process used for fabricating polysilicon gates of other devices, wherein the other devices are not CCDs. The ion implantation technology is mainly characterized in that when the polysilicon gates on the CCD are fabricated, the conventional ion implantation doping process is adopted to perform phosphorus ion implantation doping processing on the polysilicon gates on the CCD. The application of the ion implantation technology in the CCD fabrication and the CCD fabrication technology have the benefits that the technology capability during the CCD fabrication is improved, multiple problems of the prior art are solved, the performance and the quality of the CCD are ensured, and the technical foundation is provided for processing the CCD with high quality.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

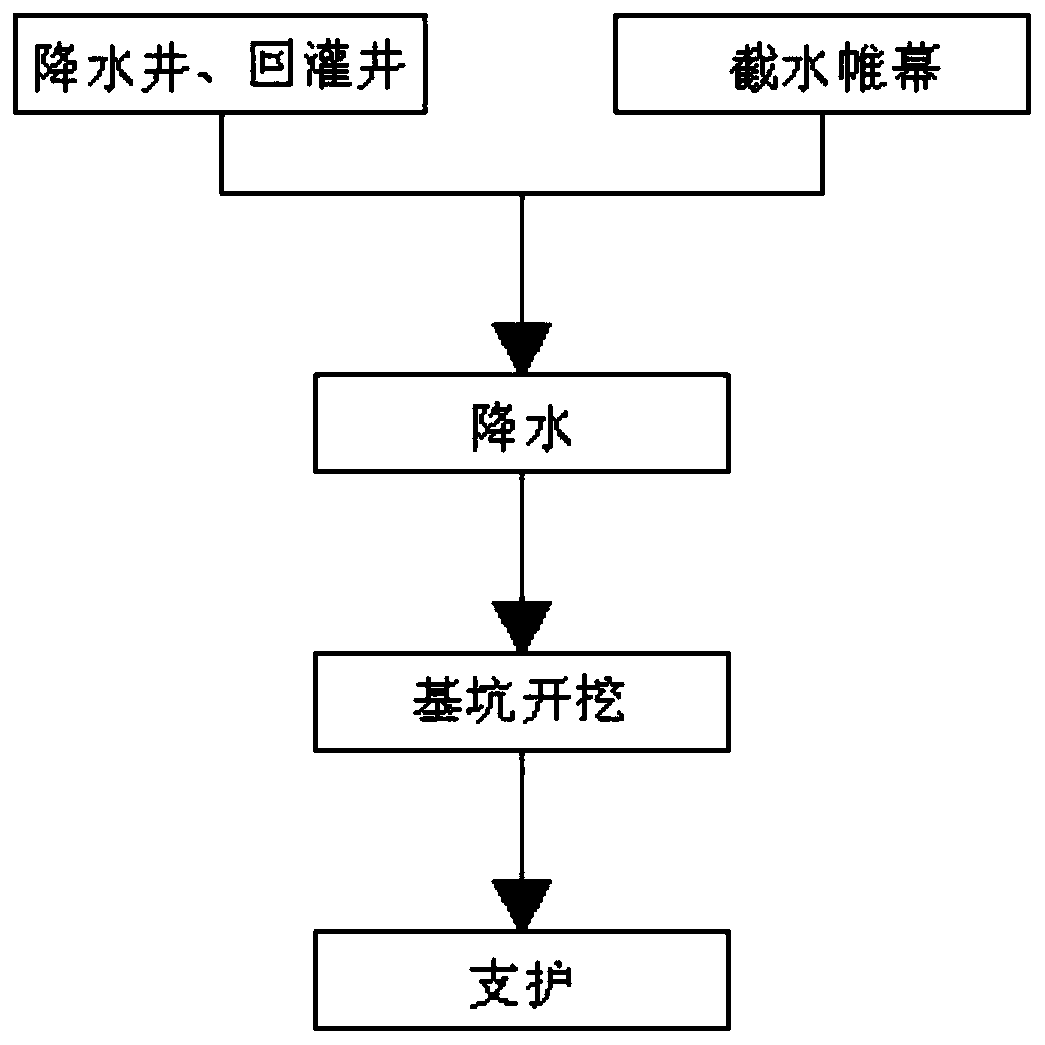

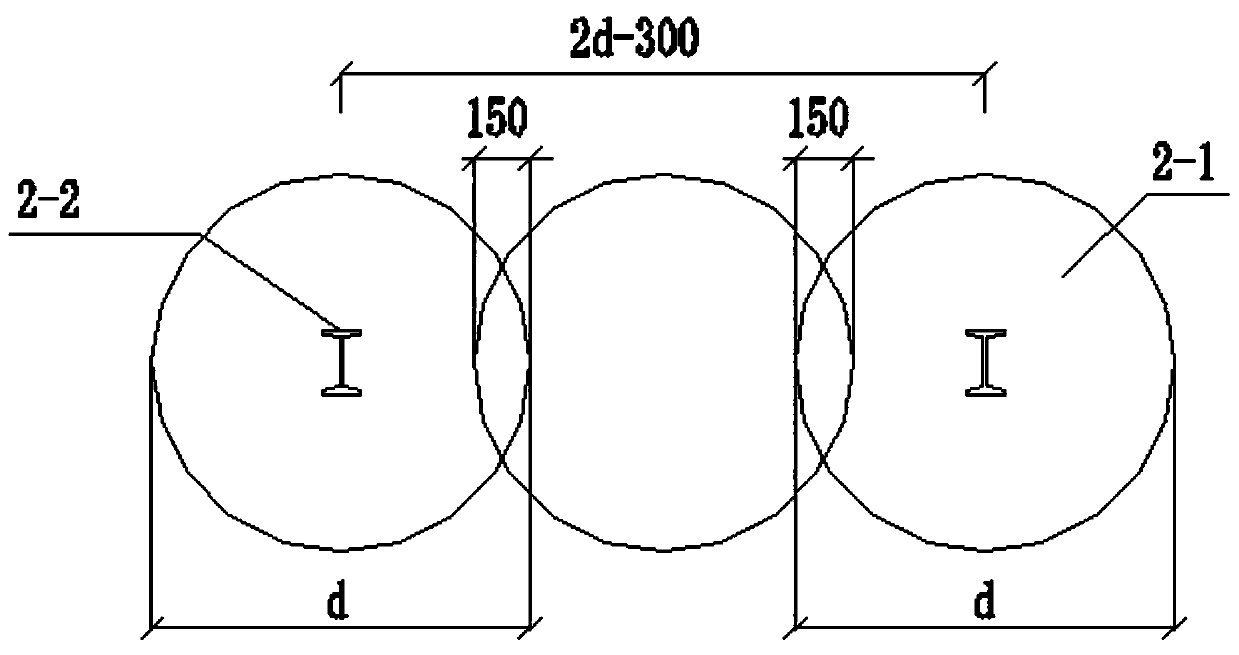

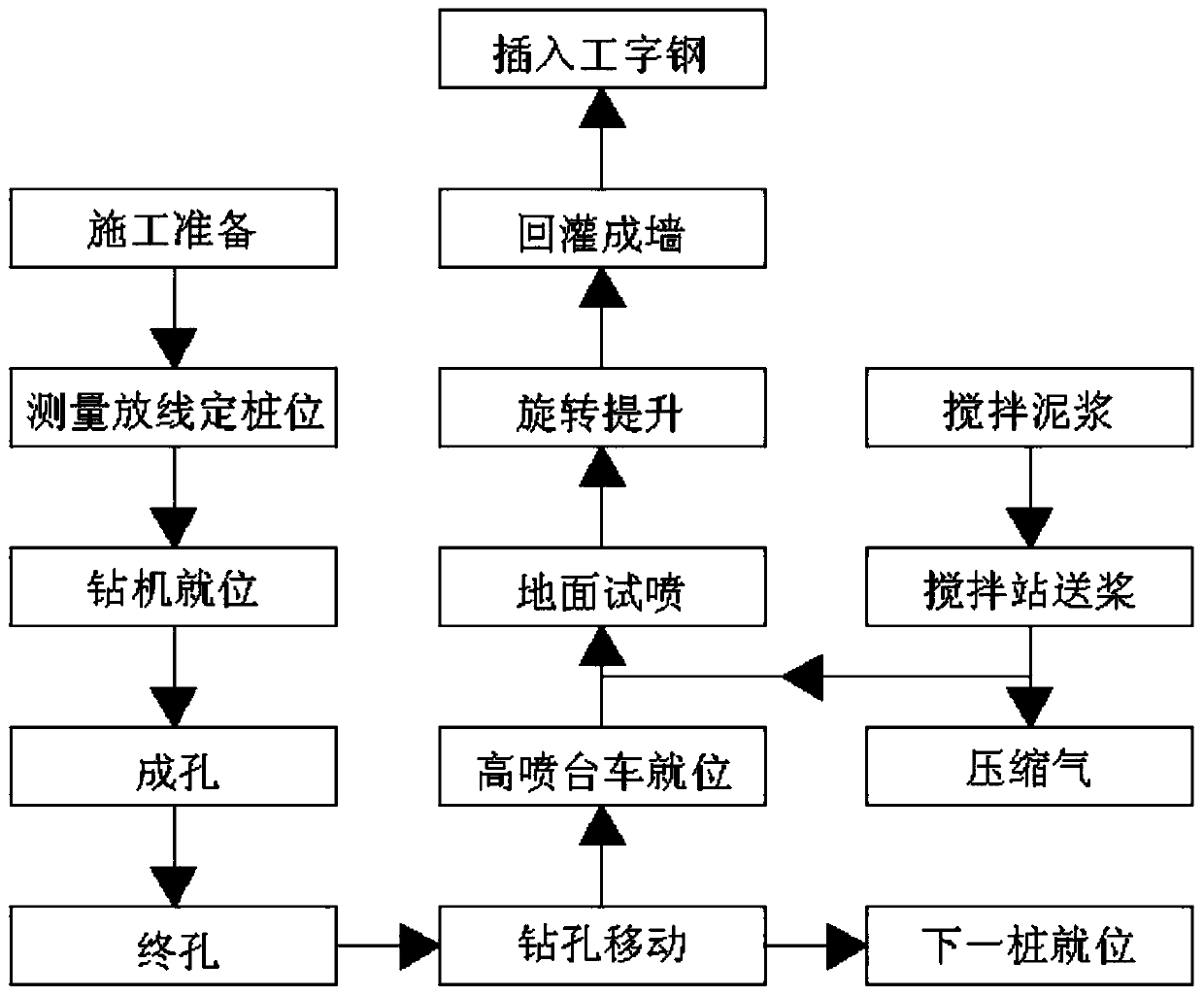

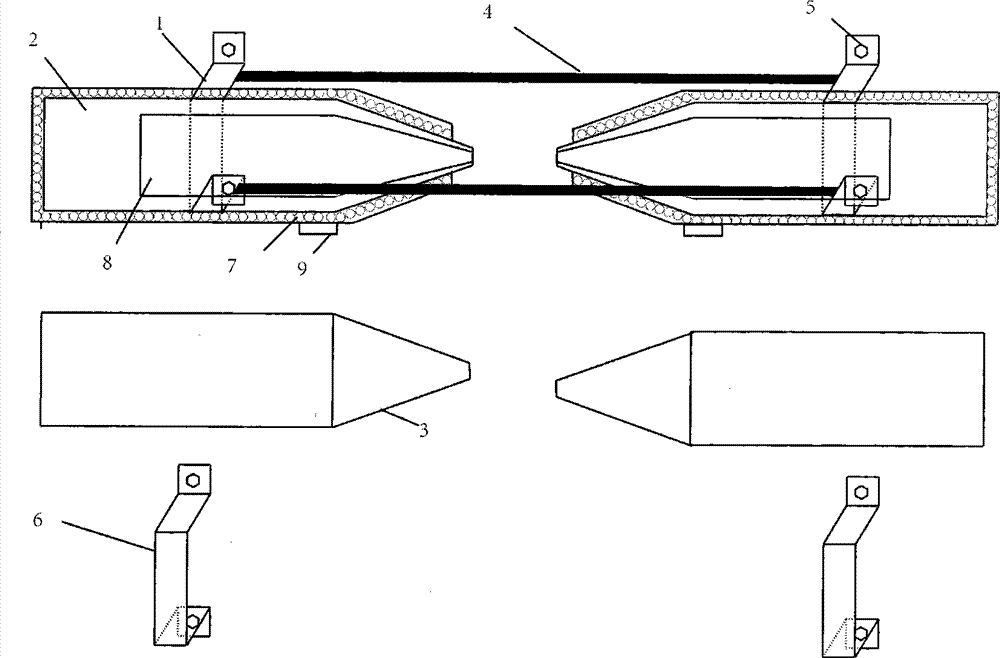

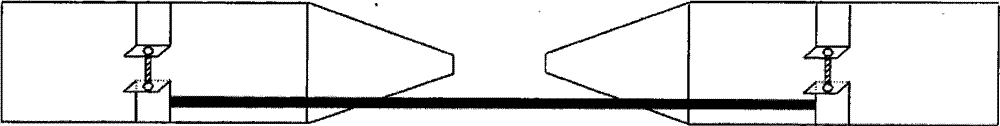

Construction method for combined supporting of deep foundation pits under complex environments

InactiveCN109881681AReduction of precipitationSmall footprint for excavationArtificial islandsExcavationsSmall footprintEngineering

The invention discloses a construction method for combined supporting of deep foundation pits under complex environments, and relates to the technical field of building construction. The constructionmethod for combined supporting of the deep foundation pits under the complex environments is characterized by comprising the following steps: a waterproof curtain of a high pressure jet grouting pileis constructed through a two-tube method, and according to an adopted two-tube method high pressure jet grouting construction process, two media of high pressure cement paste and compressed air are conveyed to the design depth to be cut, stirred and replaced to form a cement soil impermeable wall to reinforce a foundation and stop water. According to the construction method for combined supportingof the deep foundation pits under the complex environments, rainfall around the foundation pits can be reduced and avoided, negative influences such as sedimentation and cracking caused by rainfall to surrounding buildings are prevented, meanwhile the occupied area of foundation pit excavation is small, excavation can be conducted without sloping, the I-shaped steel waterproof curtain is additionally inserted in the adopted high pressure jet grouting pile, the water stopping effect is achieved, the purpose of reinforcing slopes of the foundation pits is also achieved, at present, mature implementation processes and equipment exist, a technology is feasible, and economical and practical effects are achieved.

Owner:CHINA MCC17 GRP

Multifilament tensile test sample preparation apparatus

ActiveCN104713755AMature equipmentMature technologyPreparing sample for investigationTemperature controlFiber bundle

The invention relates to a multifilament tensile test sample preparation apparatus, an accessory mainly comprises a reinforcing part and a heating part, and the reinforcing part comprises a melt adhesive cavity, a cavity top cover and a reinforcing support, and the heating part comprises an electrical heating layer and a temperature controller outside an integral support. The sample preparation apparatus can overcome the partial disadvantage of intensity measurement by fiber bundle, problems of easy pinch-off if fiber while testing and difficult control of clamping force can be solved, difficulty of easy bending of the fiber bundle when the fiber bundle is clamped can be simultaneously solved, discrete degree of the test result is reduced, experiment credibility and experiment data accuracy can be increased, a filament stretching experiment can be carried out through the experiment equipment, result accuracy is increased, the hot melt adhesive can be used in the cavity, cycle usage of the accessory is realized, and cost is saved.

Owner:苏州赛力菲陶纤有限公司 +2

Preparation method of natural perfume suitable for cigarette blasting beads

PendingCN111040876AEasy to handleImprove work efficiencyTobacco smoke filtersEssential-oils/perfumesCapric triglyceridesDistillation

The invention discloses a preparation method of a natural perfume suitable for cigarette blasting beads. The method comprises the following steps: adding caprylic capric triglyceride of which the massis 1-50 times that of a fragrant raw material extract into the fragrant raw material extract to achieve dilution, fully stirring and dissolving the obtained dilution at the temperature of 20-100 DEGC, filtering the dilution, carrying out molecular distillation on the obtained filtrate at the distillation temperature of 30-200 DEG C under the distillation pressure of 10 to 10<5> Pa, and collecting light components to obtain the cigarette blasting bead natural perfume product. The product prepared by the method is strong in aroma intensity and remarkable in aroma enhancement effect, and the quality of the product is obviously superior to that of common blasting-bead natural perfumes on the market. Meanwhile, the problem of poor solubility of the perfumes is solved, and processing and production of the blasting beads are facilitated. The preparation method is simple, mature in process and equipment and capable of forming industrial production, and the cigarette blasting beads produced by the method can remarkably improve the product quality and competitiveness.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

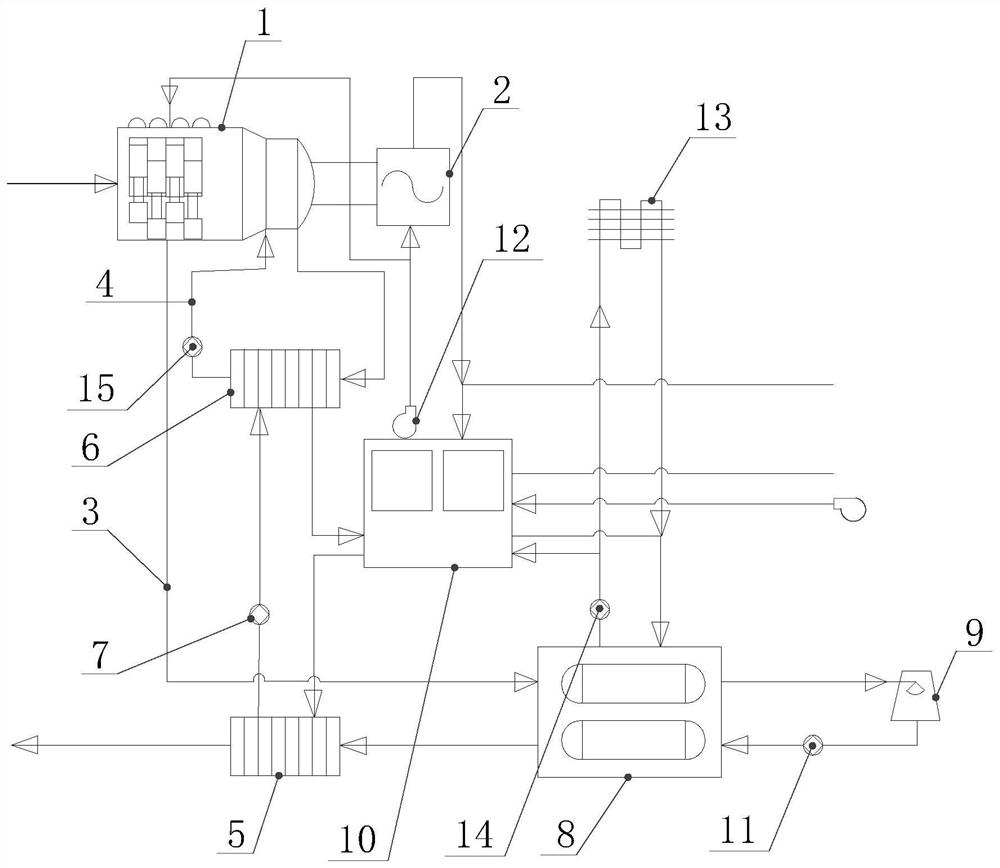

Machine room fresh air cooling, dehumidifying and desalting system driven by power waste heat of internal combustion engine

PendingCN112611124ARealization of cooling, dehumidification and desalinationIncrease profitInternal combustion piston enginesCooling/ventillation arrangementFlue gasFresh air

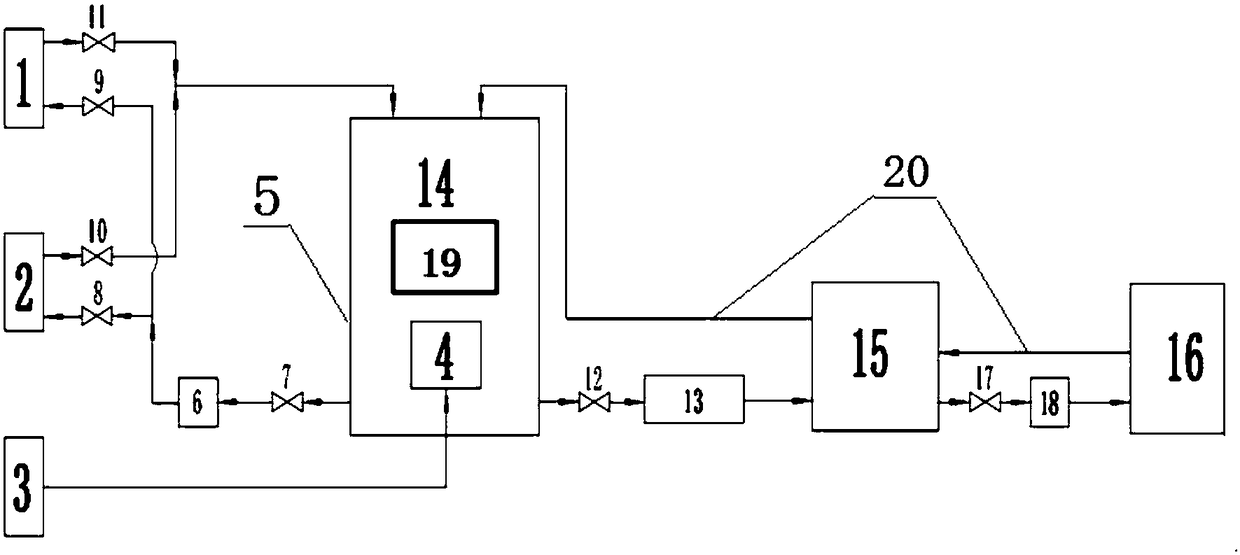

A machine room fresh air cooling, dehumidifying and desalting system driven by power waste heat of an internal combustion engine comprises an internal combustion engine power unit including a power output shaft, an internal combustion engine electricity generation unit which comprises a power input shaft, wherein the power input shaft is in power connection with the power output shaft and used for driving the internal combustion engine electricity generation unit to operate, an absorption type refrigerating unit which utilizes waste heat generated by the internal combustion engine power unit to produce cold energy through absorption type circulation, and an absorption type dehumidifying and desalting unit which uses flue gas waste heat and cylinder sleeve water waste heat of the internal combustion engine power unit as heat sources, and uses the cold energy produced by the absorption type refrigerating unit as a cold source to cool, dehumidify and desalinate fresh air. According to the machine room fresh air cooling, dehumidifying and desalting system, the waste heat generated by the internal combustion engine power unit in the power generation process of the internal combustion engine is fully utilized, cooling, dehumidifying and desalting of air are achieved through combination of the absorption type refrigerating unit and the dehumidifying and desalting unit, and the energy utilization rate is increased.

Owner:HAINAN SUN POWER

Method for inter-regional direct taxi calling

InactiveCN103177573BImprove operational efficiencyAlleviate the social problem of difficulty in taking a taxiRoad vehicles traffic controlMobile antennasInformation processing

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

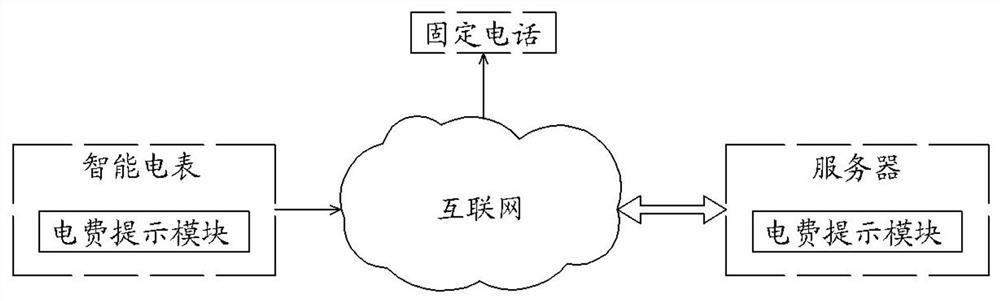

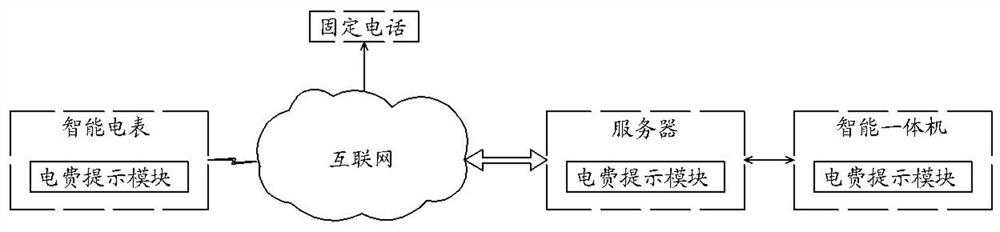

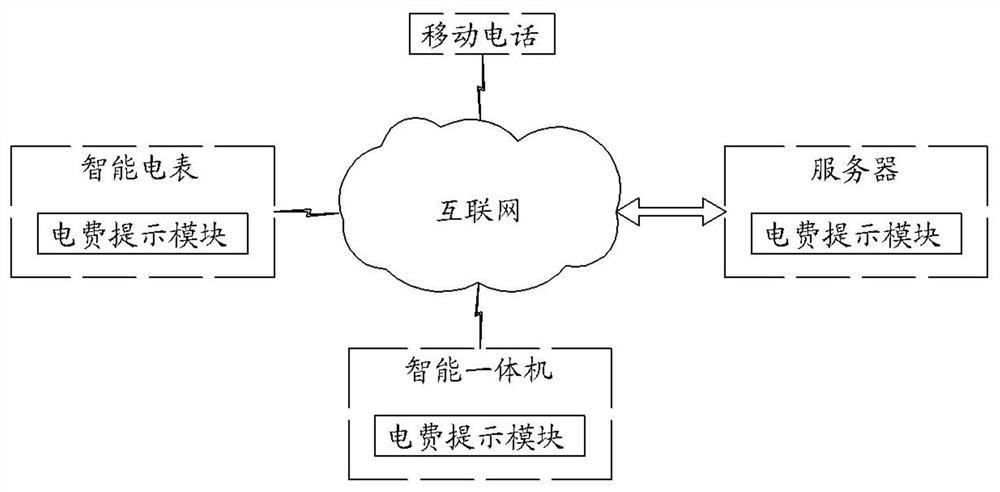

Electric power payment system and method

InactiveCN111612977AImprove work efficiencyImprove experienceMessaging/mailboxes/announcementsTransmissionTelecommunicationsSmart meter

The invention discloses an electric power payment system and method, and relates to the technical field of electric power service equipment and management. The system comprises an intelligent electricmeter, a server side, a management side and an electric charge prompting module, wherein the intelligent electric meter is connected with the management terminal and is in one-way communication withthe management terminal, the management terminal is connected with the service terminal and is in two-way communication with the service terminal, the electric charge prompting module is used for receiving and storing monthly consumption information sent by the intelligent electric meter by the management terminal, and the management terminal sends the monthly consumption information to the service terminal of a corresponding user and sends recommended payment information at the same time. The method comprises the following steps: an electric charge prompting step: an intelligent electric meter sends monthly consumption information to a management terminal every month, the management terminal receives and stores the monthly consumption information sent by the intelligent electric meter, and the management terminal forwards the monthly consumption information to a server of a corresponding user and sends recommended payment information at the same time; through the intelligent electricmeter, the server side, the management side, the electric charge prompting module and the like, high working efficiency and good experience in the process of prompting to pay the electric charge are realized.

Owner:国网河北省电力有限公司灵寿县供电分公司 +2

Manufacturing process of LED bulb with driver arranged inside

ActiveCN106195697AMature technologyHigh degree of mechanizationSemiconductor devices for light sourcesButt jointCooling effect

The invention provides a manufacturing process of an LED bulb with a driver arranged inside. The manufacturing process is characterized in that the process comprises the assembling procedures of connection of a packaging column and a special driving power source, point butt-joint of a lamp filament, testing, sealing and exhausting, gluing, lamp base feeding, aging testing and packaging, and the driving power source is located in a bulb shell. The LED bulb comprises the driver and the shell, the driver is fixed in the shell which is composed of a shell cover and a packaging panel, identical packaging column mounting holes are formed in the center of the driver, the center of the shell cover and the center of the packaging panel correspondingly, and the packaging column mounting holes are in clearance fit with the packaging column; and two electrode wire holes are formed in the two sides of the packaging column mounting hole in the shell cover correspondingly, the packaging panel is an integrated circuit board, input electrode wires of the driver penetrate through the electrode wire holes, output conductor wires of the driver are connected with the packaging panel, and electrode branch wires are fixed to the upper end of the packaging panel. The assembling process of the LED bulb comprises the steps of connection of the driver and the packaging panel, shell cover installation, testing, and power source assembling. According to the manufacturing process, the mechanization degree is high, the labor intensity is low, product quality is high and stable, the cooling effect is good, and the service life is long.

Owner:福州圆点光电技术有限公司

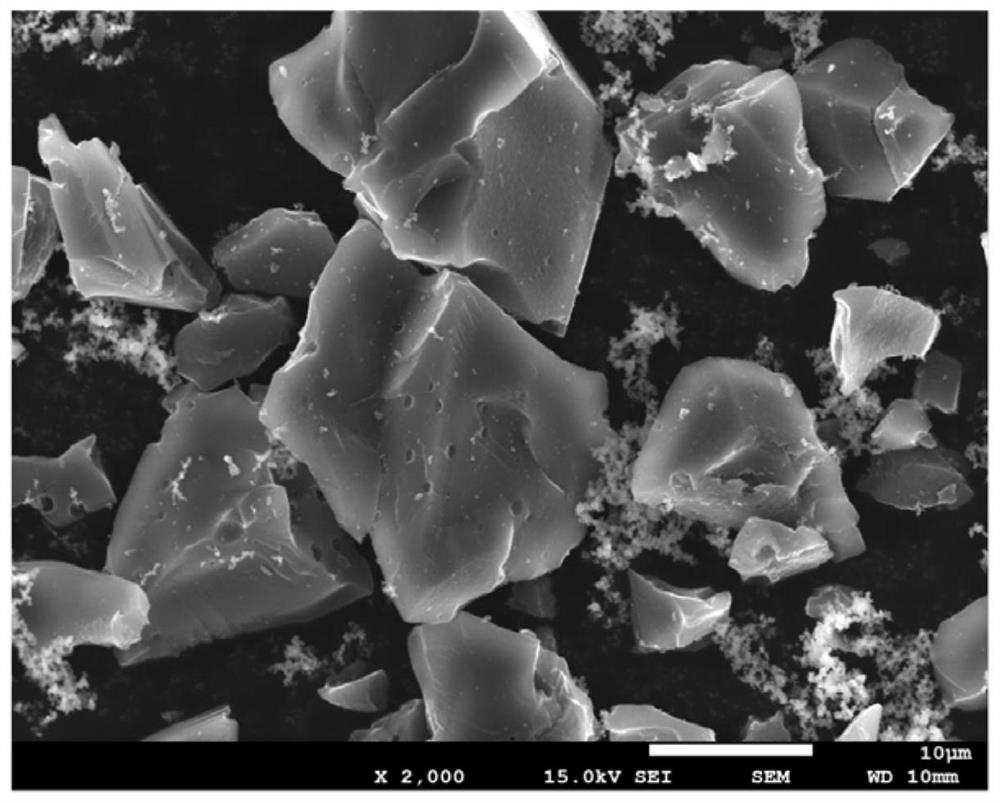

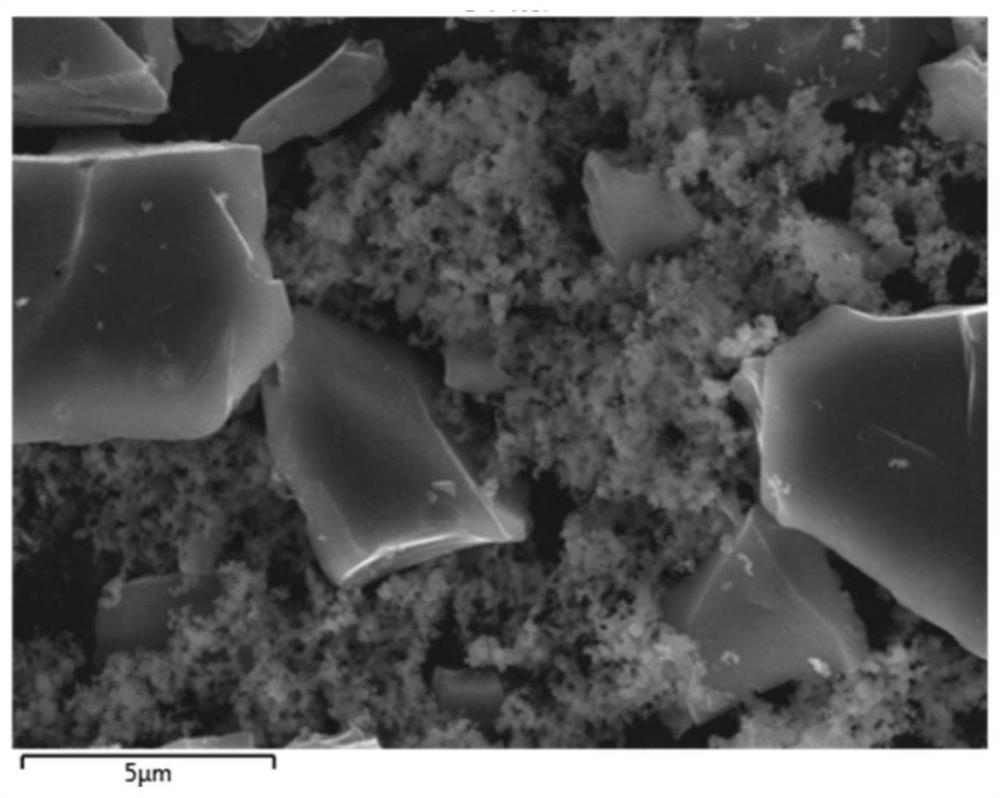

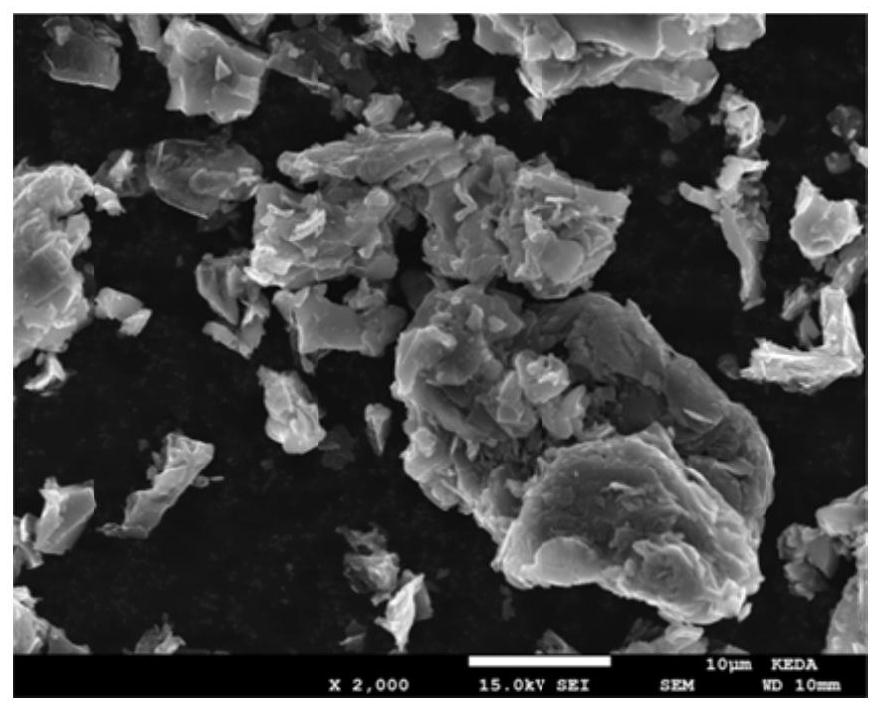

Composite negative electrode material for lithium ion battery, and preparation method thereof

InactiveCN112968155AImprovement ratioReduce lithium ion lossSiliconCell electrodesSilicon particleCarbon source

The invention discloses a composite negative electrode material for a lithium ion battery, and a preparation method thereof. The composite negative electrode material comprises a carbonaceous material, silicon particles and coated carbon, and the carbonaceous material is not subjected to graphitization treatment and has a disordered microcrystalline structure; the size of silicon grains in the silicon particles is smaller than 15 nm; and the coated carbon is amorphous carbon formed by cracking a carbon source material in a high-temperature state, and at least parts of the surfaces of the carbonaceous material and the silicon particles are covered by the coated carbon. Compared with graphite, the composite negative electrode material prepared by the invention has the advantages that the carbonaceous material can obviously improve the multiplying power and has low-temperature performance and long cycle performance, the silicon particles can obviously improve the specific capacity of the composite negative electrode material, and the coated carbon can reduce the early-stage lithium ion loss and improve the structural stability of the material; and the first reversible capacity of the composite negative electrode material reaches 600 mAh / g or above, the first efficiency is more than 85%, the price of raw materials is low, the preparation process and equipment are mature, and the composite negative electrode material is suitable for large-scale production.

Owner:赣州立探新能源科技有限公司

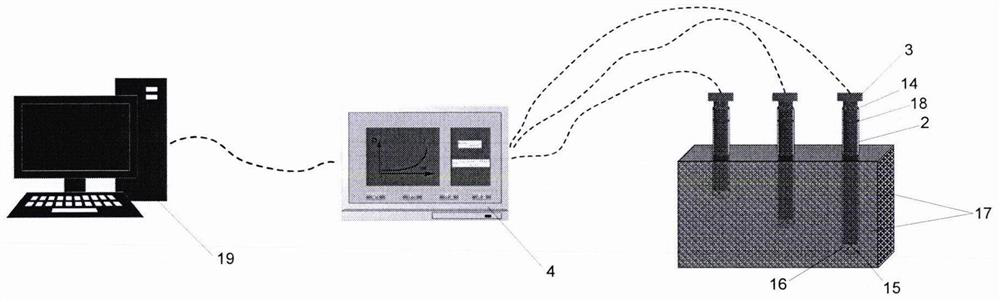

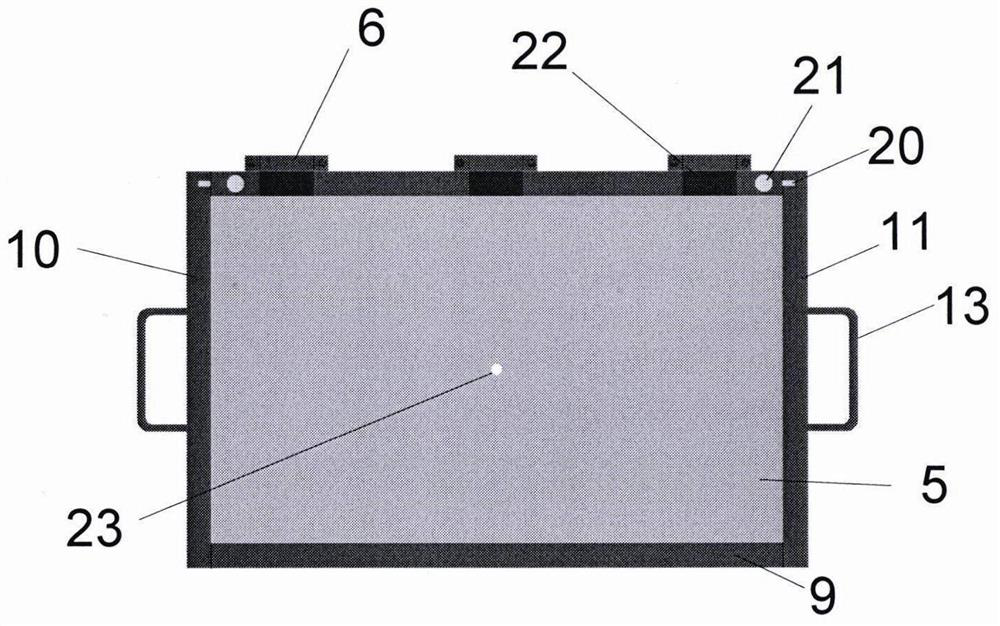

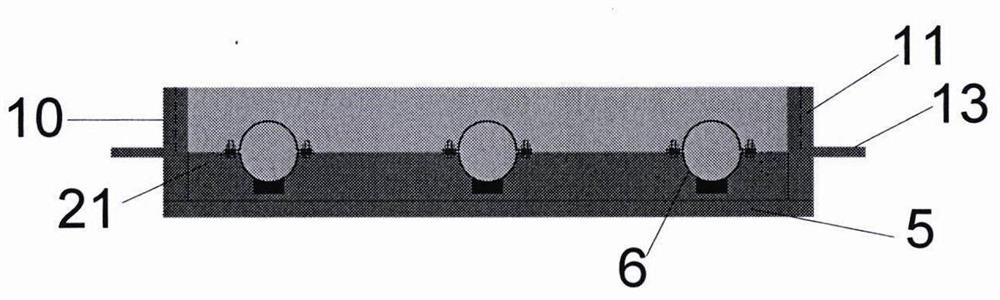

Device and method for measuring moisture diffusion coefficient of cement-based material

PendingCN114324106AShorten the timeMature equipmentSurface/boundary effectMaterial testing goodsMoisture diffusionProcess engineering

The invention discloses a cement-based material moisture diffusion coefficient determination device and a determination method, and relates to the field of cement-based material physical property parameter determination. The measuring device comprises a mold used for fixing an embedded pipe and pouring a cement-based material test piece; the embedded pipe is used for placing a temperature and humidity sensor; the temperature and humidity sensor is used for collecting humidity data; and the portable data analyzer is used for analyzing the humidity data and displaying a result and can be connected with the computer. The device can effectively measure the moisture diffusion coefficient of the cement-based material, is simple and portable, is convenient and easy to operate, can quickly analyze and display a result, solves the problem that the moisture diffusion coefficient is difficult to quickly measure, and provides actually measured physical property parameters for durability analysis of the cement-based material. The device is suitable for testing the moisture diffusion coefficient of the cement-based material under the same conditions in laboratory scientific research tests and engineering sites, and can be popularized and applied as a standard device and a standard method.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

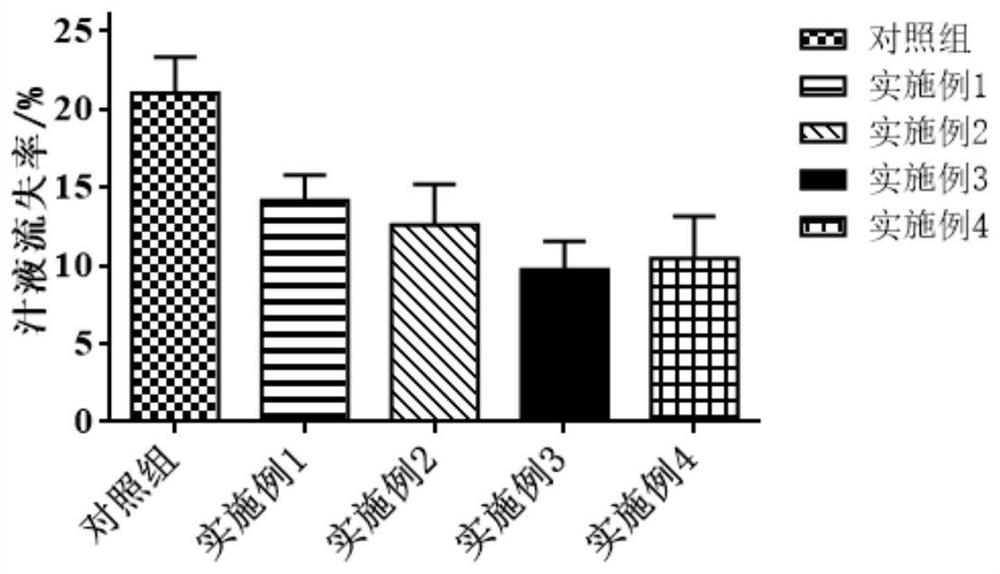

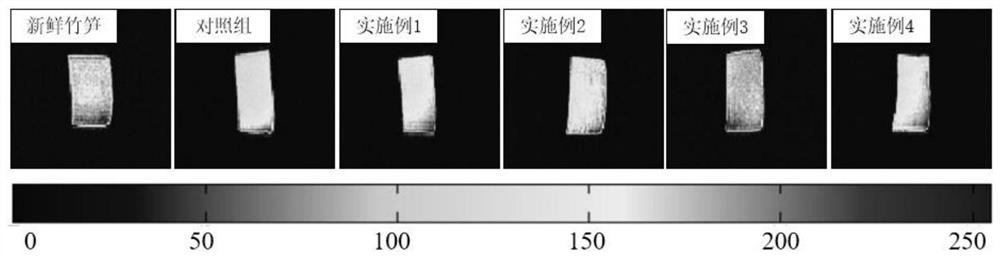

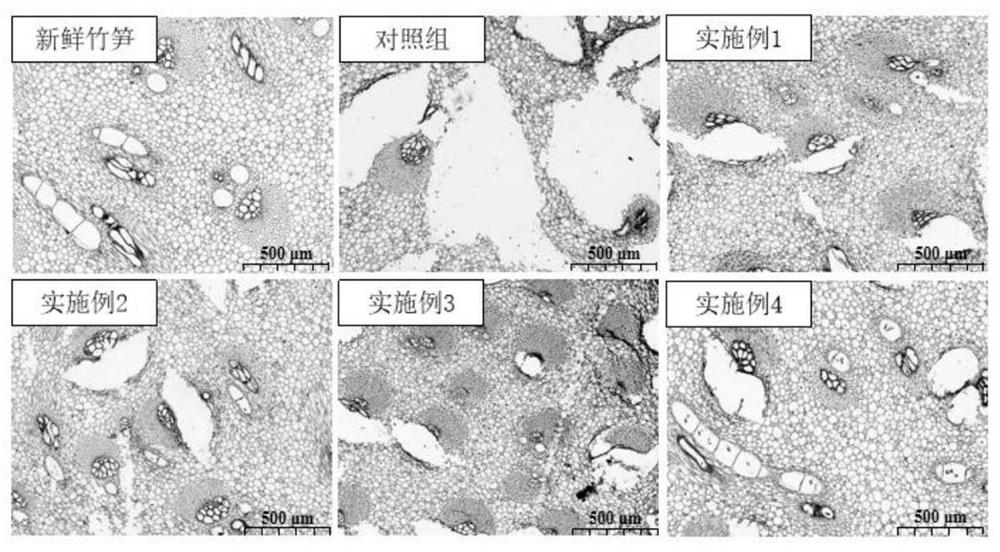

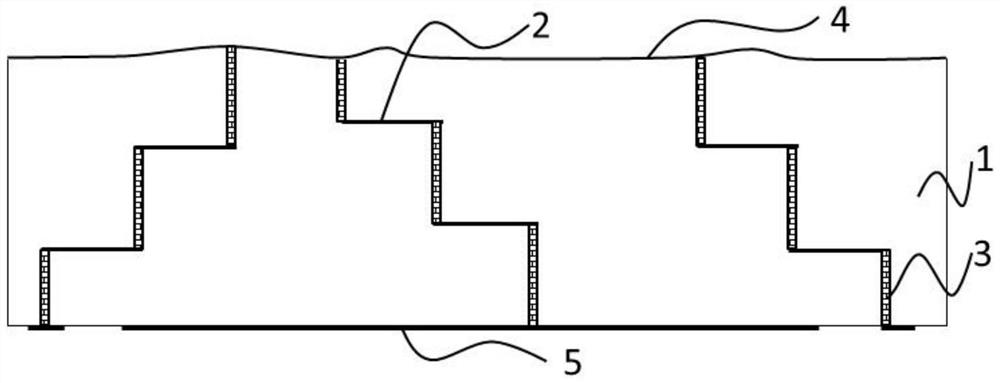

Quick-freezing method for keeping original quality of bamboo shoots

PendingCN114041498AGood economic valueMature equipmentSugar food ingredientsFood freezingChemistrySodium erythorbate

The invention provides a quick-freezing method for keeping the original quality of bamboo shoots, and belongs to the technical field of vegetable freezing. Edible bamboo shoots are placed in a mixed aqueous solution of glucose, trehalose, glycyrrhizic acid and sodium D-erythorbate to be soaked and air-dried, and then in an electrostatic field generation device, the edible bamboo shoots are placed at the position 10-40 cm away from an electrostatic field generation plate, wherein the quick-freezing temperature ranges from -55 DEG C to -30 DEG C, and the electrostatic field assists in quick-freezing for 20-80 min. Quick-frozen bamboo shoots are obtained and then soaked in a sodium D-erythorbate solution and taken out, and a layer of ice glaze with a stable structure is adopted for coating, so that the bamboo shoots can be stored for a long time, and the original quality of the bamboo shoots can be kept. The interior quality and flavor of the quick-frozen bamboo shoots are close to those of fresh bamboo shoots, meanwhile, the treatment method is conventional, equipment is mature, and the commercial potential is huge.

Owner:INST AGRO PROD PROCESSING ANHUI ACADEMY AGRI SCI

Method for manufacturing high-precision fine lines on high-flatness surface of LTCC substrate

ActiveCN111683459AHigh precisionSmooth edgesConductive pattern polishing/cleaningConductive material removal by irradiationElectrical conductorHemt circuits

The invention relates to a method for manufacturing high-precision fine lines on a high-flatness surface of an LTCC substrate. The method comprises the following steps: 1, smoothing the surface of a sintered multilayer LTCC circuit substrate; 2, manufacturing a conductor pattern on the surface of the ground substrate; 3, precisely modifying the conductor pattern to obtain high-precision fine lines; 4, carrying out post-treatment on the precisely modified substrate to eliminate edge slag of the high-precision fine lines. By adopting the method to manufacture the LTCC surface high-precision finelines, high surface flatness can be obtained, conductor pattern arrangement is flexible, line fineness is small, precision is high, edges are smooth, the method has high compatibility with a materialsystem, and required equipment and processes are mature.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

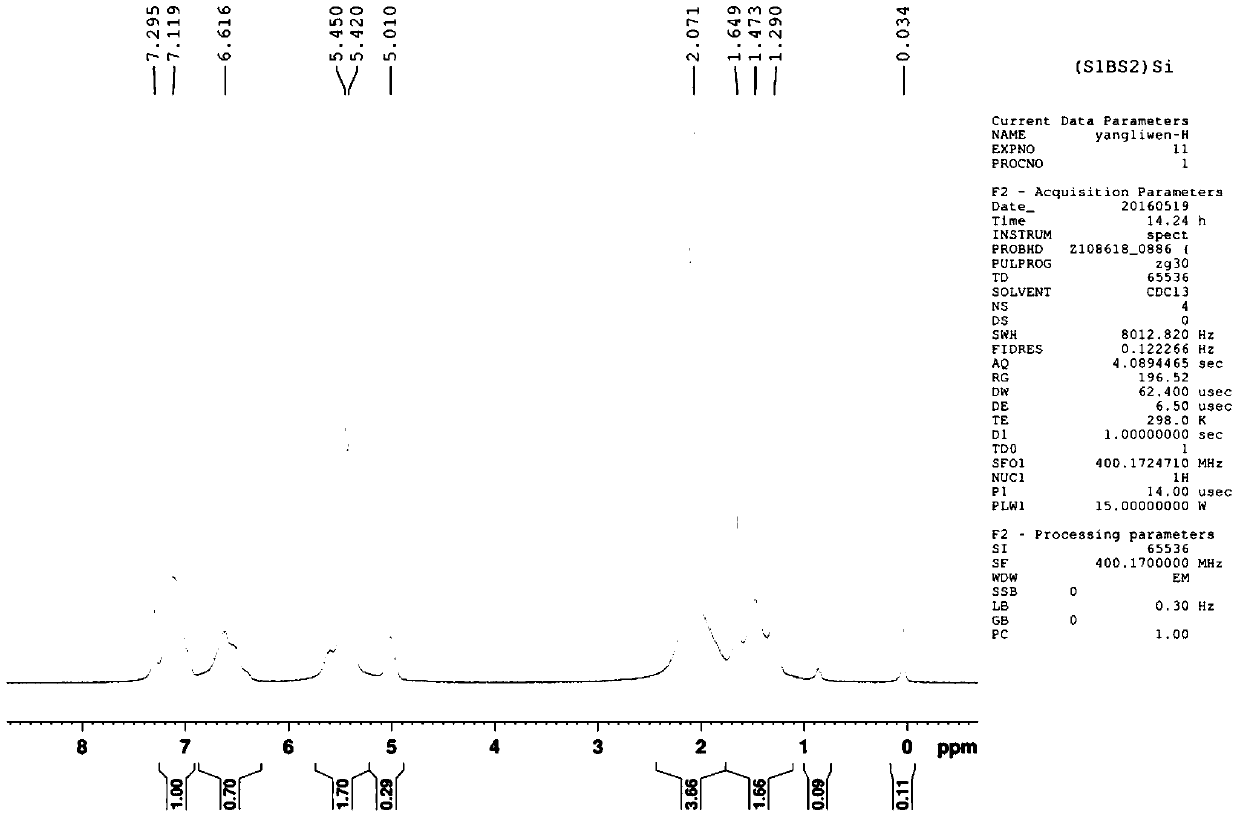

A kind of asymmetric star-shaped styrene-butadiene rubber and its preparation method and application as sole rubber material

The invention provides an asymmetric star type styrene-butadiene rubber, and a preparation method thereof and applications of the asymmetric star type styrene-butadiene rubber as a sole rubber material, wherein the asymmetric star type styrene-butadiene rubber has a polystyrene-polybutadiene-polystyrene triblock asymmetric polymer arm. The preparation method comprises: in a system containing an organic single lithium initiator, sequentially adding most of styrene, polymerizing, adding butadiene, polymerizing, adding a small part of styrene, polymerizing, adding a coupling agent after completing the polymerizing, and carrying out a coupling reaction to obtain the asymmetric star type styrene-butadiene rubber. The prepared asymmetric star type styrene-butadiene rubber of the present invention has characteristics of high tear strength, high wear resistance and good processing property, and can be used for preparing the sole with characteristics of wear resistance, excellent wet-skid resistance, excellent elasticity, and wearing comfort.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite energy storage device and energy storage method thereof

PendingCN108204761AReduce use costMature equipmentHeat storage plantsEnergy storageAutomotive engineeringElectric heating

The invention discloses a composite energy storage device. The composite energy storage device comprises an energy storage water tank. The energy storage water tank is connected with a solar device, an air source heat pump and a terminal. The energy storage water tank is internally provided with a thermocouple which is connected with an electric heating controller. The invention further disclosesan energy storage method of the composite energy storage device. Three energy manners of the solar energy, the air energy and the thermocouple are used for heating an energy storage medium, the resources are integrated more scientifically and reasonably, and the using cost is greatly reduced. Moreover, the tree heating technologies and equipment are relatively mature, simple and reliable, technical integration is relatively easy, the cost is low, application and popularization are easy, and the energy saving effect is good. Water serves as the energy storage medium, water is attractive in quality and price, no pollution is caused in the energy storage and energy releasing process, and the process is relatively environmentally friendly.

Owner:贵州翠谷地暖科技有限公司

Production method of formed coke

ActiveCN102079982BIncrease the drying processHigh calorific valueCoke quenchingEnergy inputRisk strokeWater jacket

The invention discloses a production method of formed coke. In the method, the working procedure of drying formed coke is added, thus the carbonization time can be shortened, the calorific value of dry distillation gas can be increased, and the large-scale production of formed coke can be ensured; an external combustion type carbonization furnace is used in the carbonization process, the carbonization equipment has long flue stroke, the residence time of flue gas is long and the thermal efficiency is high; the quantity of heat can be adjusted to ensure the carbonization quality of the formed coke; the integration of carbonization and dry quenching can be realized, energy-saving analysis is performed on the energy requirement and supply of the carbonization process and a specific energy-saving scheme is provided; a specific temperature control scheme of the carbonization process is provided particularly for the carbonization of formed coke prepared from calcium carbide; and a novel water jacket is used for dry quenching, thus the water content of the formed coke product can be reduced, the water pollution can be prevented, the energy can be saved and the strength of formed coke canbe increased. The formed coke produced by the method meets the quality requirements, the operating cost is low, the floor space is small, the investment is less, the technology and equipment are mature and the industrial and large-scale production can be realized.

Owner:YIBIN TIANYUAN GRP CO LTD

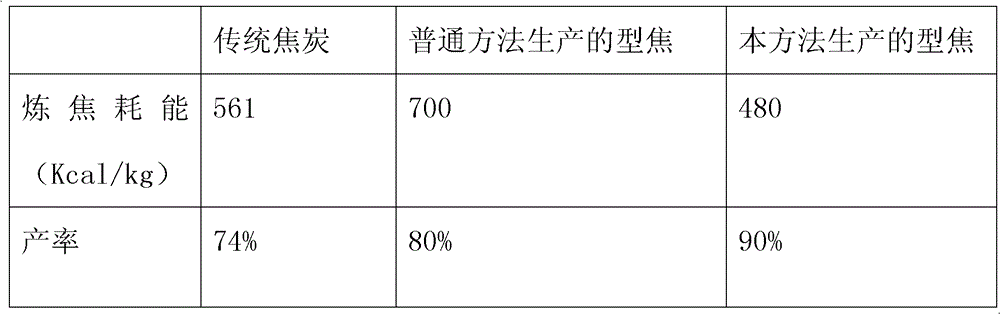

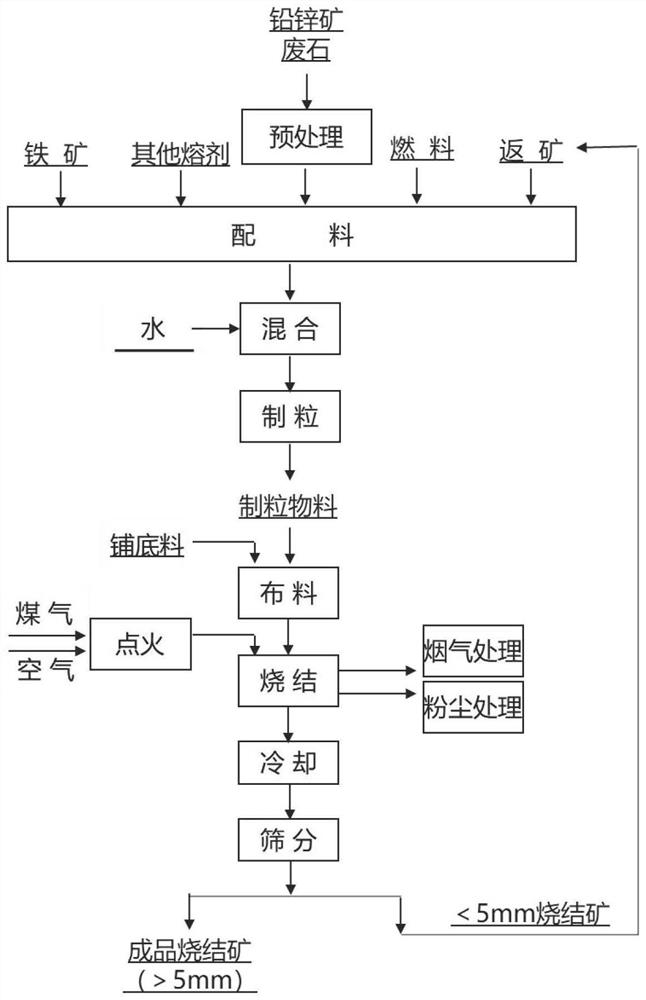

Comprehensive utilization method of lead-zinc ore waste rock

PendingCN114369717AEfficient recyclingEfficient use ofProcess efficiency improvementMining engineeringDolomite

The invention discloses a comprehensive utilization method of lead-zinc ore waste rock. The comprehensive utilization method comprises the following steps: S1, crushing the lead-zinc ore waste rock in advance, and finely grinding the lead-zinc ore waste rock to a certain particle size; s2, performing fine grinding on the conventional flux in advance to a proper particle size; s3, the iron ore concentrate is pretreated, so that the iron ore concentrate has a certain specific surface area; s4, ore blending and uniform mixing are conducted on the pretreated iron ore concentrate, a conventional flux, the lead-zinc ore waste rock obtained after fine grinding and a binder according to the set MgO content and binary alkalinity, a mixture is obtained, then water is added into the mixture in a disc pelletizer for pelletizing, and green pellets with the set granularity are obtained; and S5, the green pellets are loaded into special pellet production equipment, drying, preheating, roasting, soaking and cooling are conducted at the set air speed and temperature, and the finished product oxidized pellets are obtained. Based on the characteristic that the main phase of dolomite lead-zinc ore waste rock is dolomite, the dolomite lead-zinc ore waste rock is crushed and finely ground to serve as the magnesium-containing flux to replace part of conventional metallurgical dolomite to prepare magnesium pellets, and therefore recycling of valuable components such as calcium and magnesium in the waste rock is achieved.

Owner:CENT SOUTH UNIV

Method for resource utilization of lead-zinc ore waste rocks

The invention discloses a lead-zinc ore waste rock resource utilization method which comprises the following steps: S1, crushing lead-zinc ore waste rock to obtain low-quality dolomite; or roasting the lead-zinc ore waste rock, and crushing after roasting to obtain low-weight light-burned dolomite; s2, blending the iron ore powder, return mine, a flux and coke powder to obtain a sintering raw material; wherein the flux contains low-quality dolomite or low-quality light-burned dolomite; s3, uniformly mixing the sintering raw materials to obtain a uniformly premixed material; s4, granulating the mixture to obtain a granulated material; and S5, distributing, igniting and sintering the granulated material in a sintering cup, and then cooling, crushing and screening to obtain the finished product sintered ore. According to the method, the lead-zinc ore waste rock is used for preparing the dolomite and light-burned dolomite products for sintering, the low-quality dolomite can be prepared only through mechanical crushing, or the low-quality light-burned dolomite can be fired through a conventional roasting process, the technological process is simple, the production cost is low, and high technical and economic feasibility is achieved.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD +1

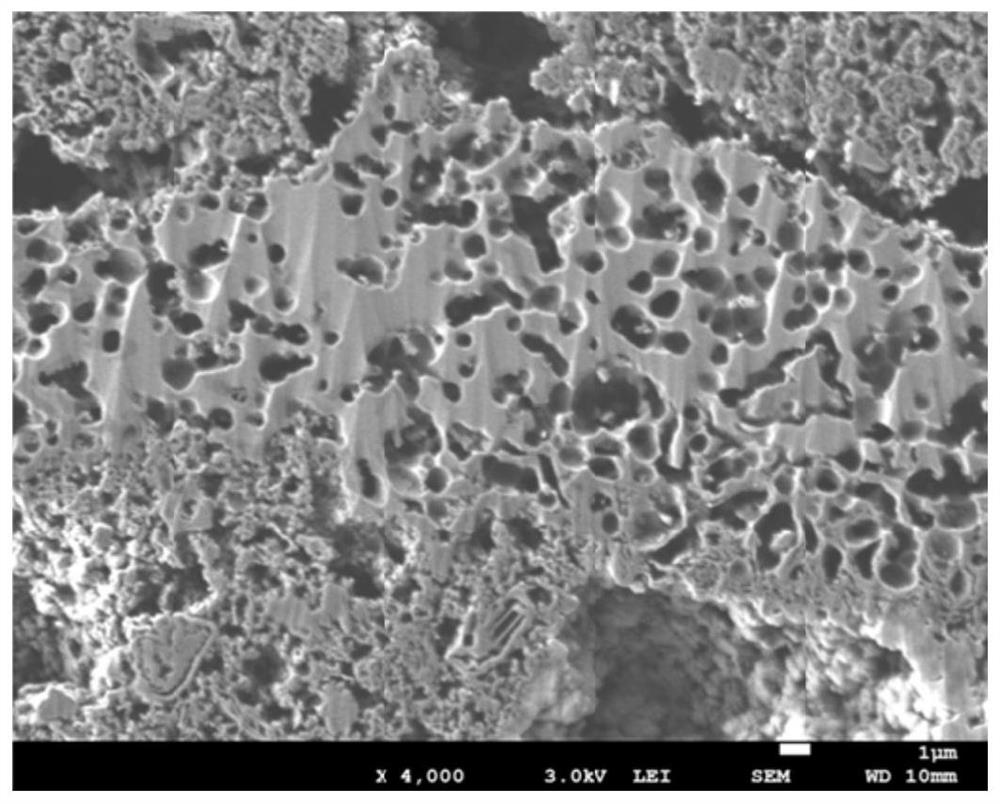

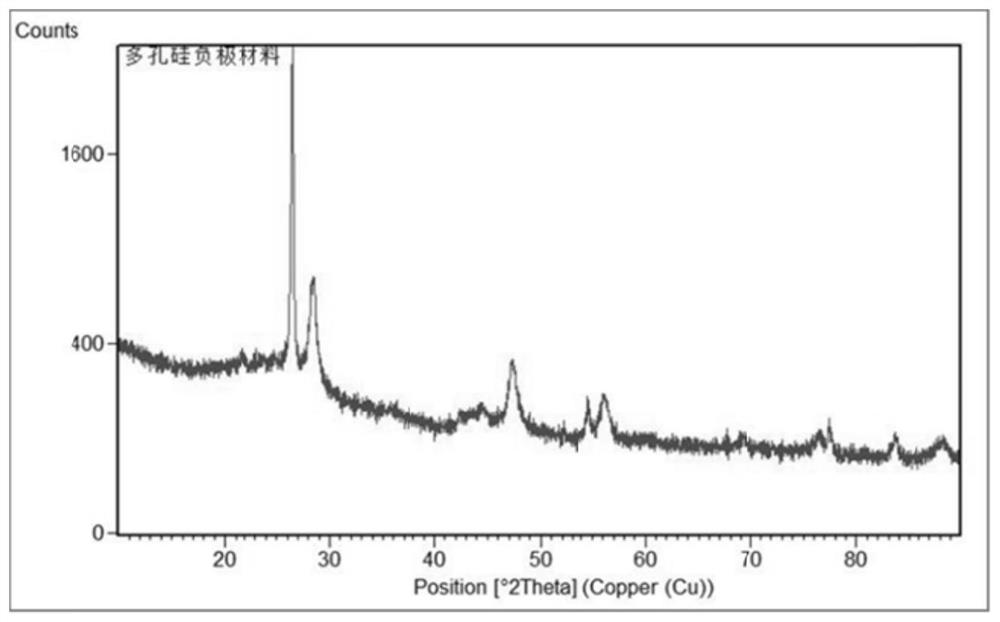

A core-shell structure porous silicon negative electrode material for lithium ion battery and preparation method thereof

ActiveCN111755677BReduce absolute volume expansionAlleviate the volume expansion effectMaterial nanotechnologyCell electrodesNanoporous siliconGraphite

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a core-shell structure porous silicon negative electrode material for lithium ion batteries and a preparation method thereof; the porous silicon negative electrode material has a core-shell structure, and the core contains nanoporous silicon, graphite and amorphous carbon, the shell is amorphous carbon; the proportion of nanoporous silicon in the negative electrode material is 30% to 70wt.%, the proportion of graphite is 20% to 45wt.%, and the proportion of amorphous carbon is 10% to 40wt. .%; the microporous silicon raw material contains 1 to 10wt.% of oxygen, and the oxygen content in the nanoporous silicon obtained by wet grinding is 12 to 35wt.%; the negative electrode material of the present invention is used as lithium ion When the negative active material of the battery is used, it can significantly increase the battery capacity, and has excellent cycle performance, and the raw material is cheap, and the preparation process and equipment are mature, which is suitable for large-scale production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com