Multifilament tensile test sample preparation apparatus

A tensile test and sample die technology, which is applied in the field of devices for preparing multifilament tensile test samples, can solve the problems of sample slippage, affecting the accuracy of experimental results, and non-perpendicular lines, and achieves outstanding substantive characteristics and equipment. and mature technology, the effect of reducing the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention are described in detail as follows:

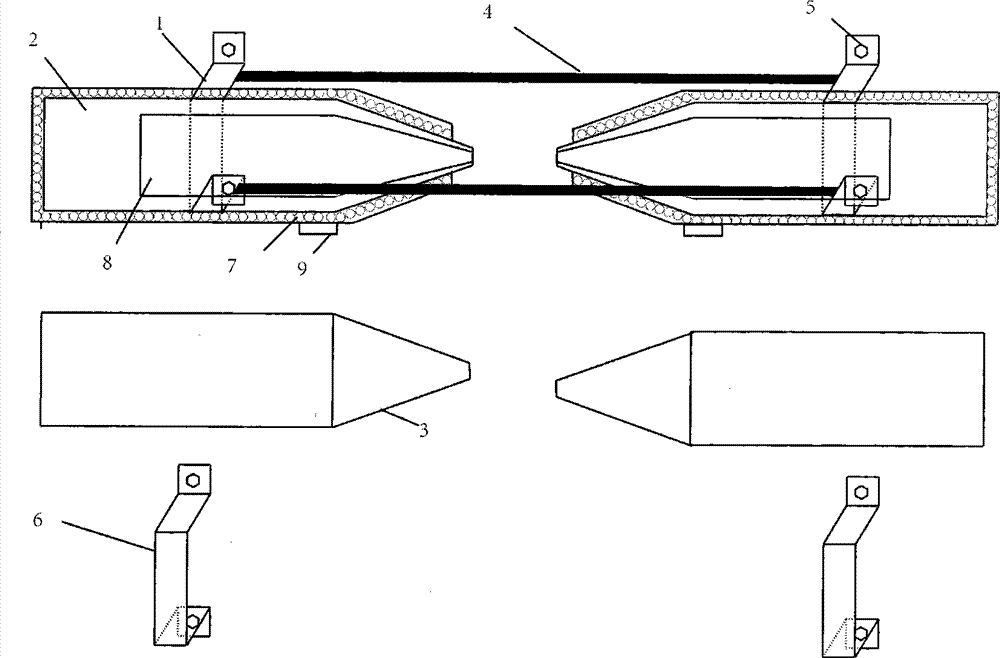

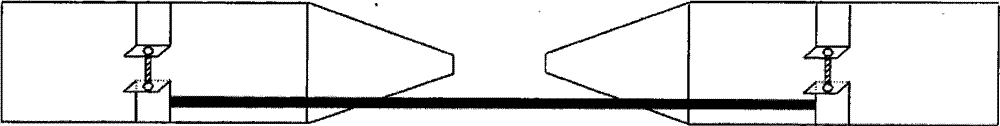

[0024] 7. As figure 1 As shown, the multifilament tensile test prepares a sample accessory, the accessory includes a reinforcement part and a heating part, the reinforcement part includes a cavity upper cover 3, a sample mold 2, a beam lower bracket 1 and an upper bracket 6, the cavity The upper body cover 3 is covered on the sample mold 2, and the sample cavity 8 is sealed. The heating part includes two parts, a point electric heating layer 7 and a temperature controller 9. The electric heating layer 7 is in contact with the sample mold 2, and a small part of the tip is kept from contacting the electric heating layer 7. The temperature controller 9 Installed on the outside of the electric heating layer 7 . The device for preparing a sample for a multifilament tensile test according to claim 1, characterized in that: the lower beam support (1) can prevent the sample from moving before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com