Method for resource utilization of lead-zinc ore waste rocks

A lead-zinc mine and resource-based technology, applied in the field of mineral processing, can solve the problems of high cost, difficulty in crushing and grinding, and lack of market competitiveness, and achieve low production cost, large production scale, and significant social and ecological benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

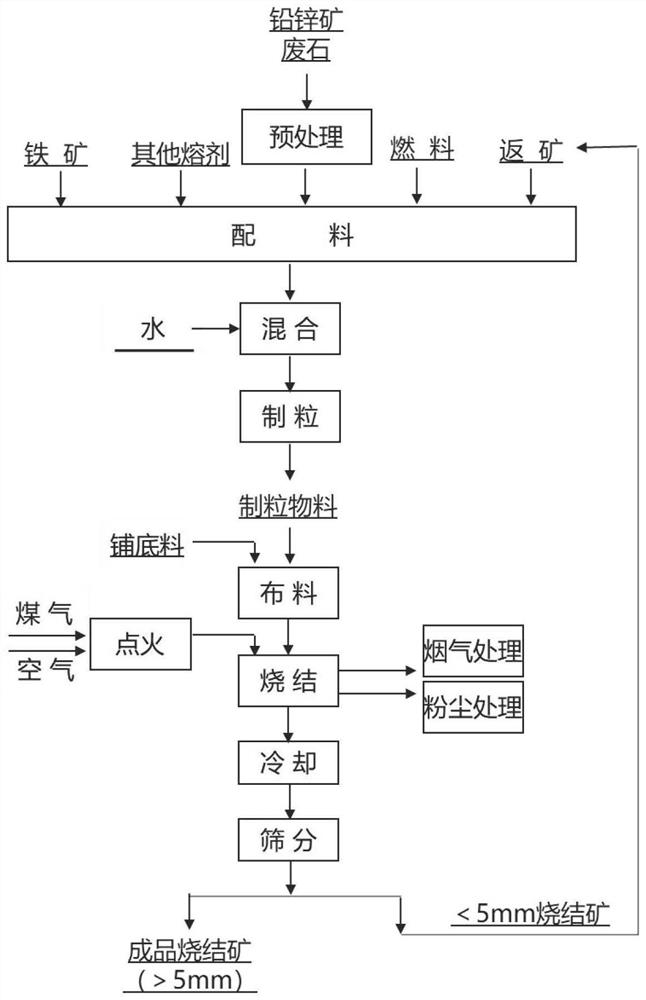

Image

Examples

Embodiment 1

[0024] A method for preparing low-quality dolomite from lead-zinc ore waste rock (27.06% CaO, 18.15% MgO, 1.43% S, 0.29% Zn, 0.1% Pb) for iron ore sintering production, comprising the following steps:

[0025] The first step: preparation of low-quality dolomite

[0026] A jaw crusher is used to crush the lead-zinc ore waste rock, and the low-quality dolomite obtained after crushing has a particle size of -3mm and a content of 58.81%.

[0027] The second step: ore blending

[0028] The proportions of iron ore powder, limestone, dolomite, low-quality dolomite (prepared in the first step), quicklime, coke powder, and returned ore are 58.83%, 6.89%, 2.39%, 1.71%, 3.00%, and 4.10%, respectively , 23.08%, the fixed sinter basicity is 1.95, in the mixed material: SiO 2 The MgO content is 5.5%, and the MgO content is 1.8%. The low-quality dolomite obtained from waste rock crushing is used to replace 40% of the traditional dolomite for sintering, and the moisture content of the mixtu...

Embodiment 2

[0037] A method for preparing low-quality dolomite from lead-zinc ore waste rock (27.06% CaO, 18.15% MgO, 1.43% S, 0.29% Zn, 0.1% Pb) for iron ore sintering production, comprising the following steps:

[0038] The first step: preparation of low-quality dolomite

[0039] Jaw crushers and roller crushers are used to crush lead-zinc ore waste rocks, and the low-quality dolomite obtained after crushing has a particle size of -3mm and a content of 100%.

[0040] The second step: ore blending

[0041] The proportions of iron ore powder, limestone, dolomite, low-quality dolomite (prepared in the first step), quicklime, coke powder, and returned ore are 58.83%, 6.89%, 2.39%, 1.71%, 3.00%, and 4.10%, respectively , 23.08%, fixed sinter basicity is 1.95, SiO in raw materials 2 The MgO content is 5.5%, and the MgO content is 1.8%. The low-quality dolomite obtained from waste rock crushing is used to replace 40% of the traditional dolomite for sintering, and the moisture content of the ...

Embodiment 3

[0050] A method for preparing low-quality dolomite from lead-zinc ore waste rock (27.06% CaO, 18.15% MgO, 1.43% S, 0.29% Zn, 0.1% Pb) for iron ore sintering production, comprising the following steps:

[0051] The first step: preparation of low-quality dolomite

[0052] The lead-zinc ore waste rock is crushed by a jaw crusher, and the low-quality dolomite obtained after crushing has a particle size of -3mm and a content of 83.49%.

[0053] The second step: ore blending

[0054] The proportions of iron ore powder, limestone, dolomite, low-quality dolomite (prepared in the first step), quicklime, coke powder, and returned ore are 58.67%, 7.00%, 1.60%, 2.55%, 3.00%, and 4.10%, respectively , 23.08%, fixed sinter basicity is 1.95, SiO in raw materials 2 The MgO content is 5.5%, and the MgO content is 1.8%. The low-quality dolomite obtained by crushing waste rock is used to replace 60% of the traditional dolomite for sintering, and the moisture content of the mixture is 8.5%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com