Production method of formed coke

A production method and technology for raw materials, applied in the production field of coke, can solve the problems of short residence time, unstable quality of coke, easy softening and deformation of coal, and achieve industrialization and scale, mature technology and equipment, and smoke. The effect of long air retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

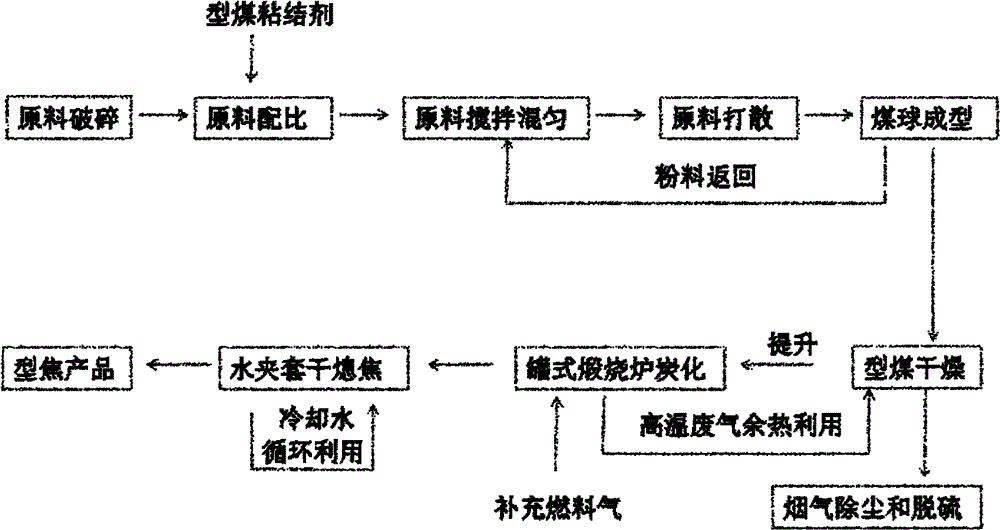

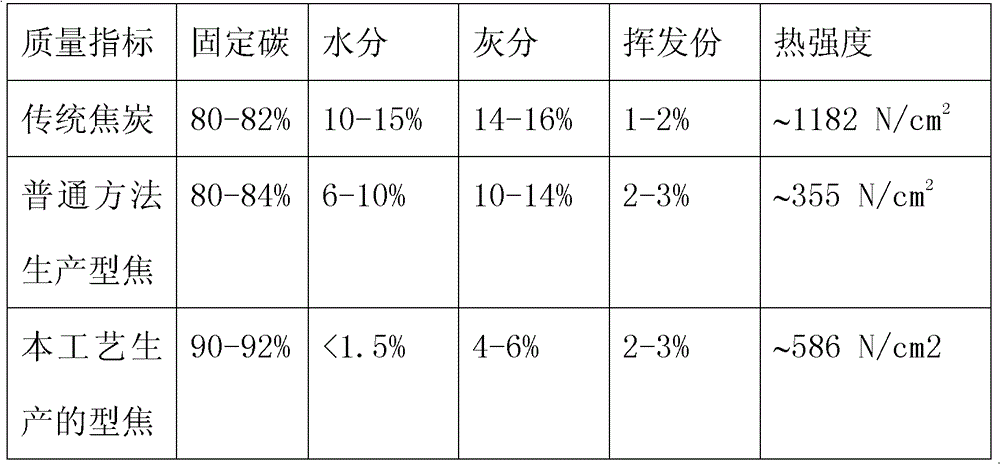

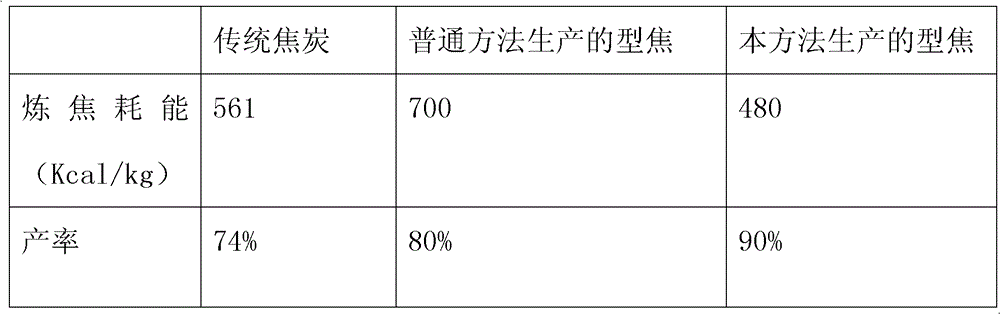

[0040] like figure 1 As shown, the raw materials of large particle bituminous coal, anthracite and coke powder have a moisture content of 8.5%. They are unloaded to the pit by truck and sent to the raw material crusher by the bucket elevator. The particle size of raw materials crushed to 85% is less than After 3mm, it is sent to the raw material warehouse for stacking with a belt. Raw material quality: 100kg of bituminous coal, 550kg of anthracite, and 350kg of coke powder are batched by the weighing belt, and then sent to the fourth-stage double-helical agitator by the bucket elevator, and the briquette liquid binder sodium humate is added according to 4% of the raw material quality. Stir and mix, and then send it to the molding machine for briquette molding after being dispersed by a homogenizer; the powder generated during the molding process is returned to the mixer for recycling.

[0041] The formed briquettes are sent to the tunnel drying kiln by the belt conveyor for d...

Embodiment 2

[0053] Raw materials are bituminous coal and anthracite, of which bituminous coal is 450kg, anthracite is 550kg, and the moisture percentage of raw material is 12.5%. It is unloaded to the pit by car, sent to the raw material crusher by bucket elevator, and crushed to 85% of the raw material particle size. After they are all less than 3mm, they are sent to the raw material warehouse by belt for stacking. It is sent to the four-stage double-helical agitator by the bucket elevator, and the briquette dry powder binder potassium humate is added according to 2.6% of the raw material mass, and stirred and mixed, and then dispersed by the homogenizer and sent to the molding machine for briquette forming ; The powder generated during the molding process is returned to the mixer for recycling.

[0054] The formed briquettes are sent to the briquette dryer, that is, the vertical drying kiln, through a belt conveyor for drying. The heat source for drying is the high-temperature flue gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com