Comprehensive utilization method of lead-zinc ore waste rock

A technology of lead-zinc ore and iron concentrate, which is applied in the field of mineral processing, can solve the problems of relying on the size of the surrounding building materials market, the limitation of lead-zinc ore waste rock consumption, and the low added value of building material products, so as to achieve low cost and resource utilization Efficient utilization, significant economic and social ecological benefits, promotion of oxidation and decomposition of sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

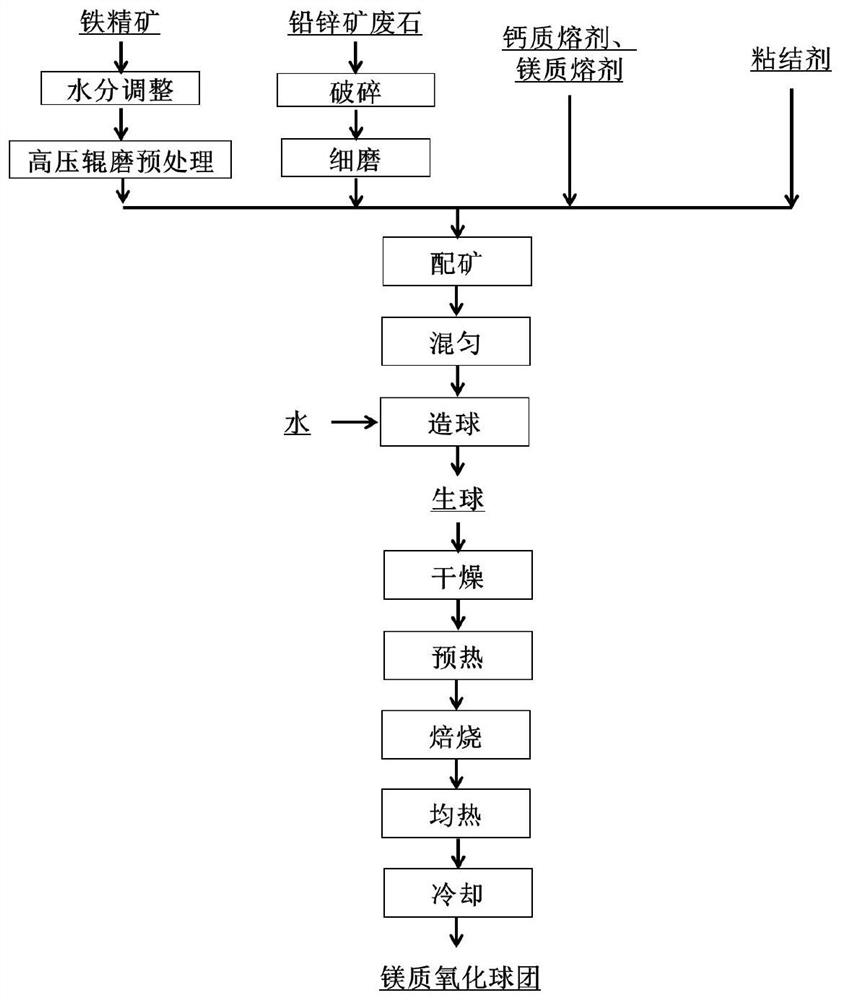

Method used

Image

Examples

Embodiment 1

[0030] A kind of lead-zinc ore waste rock (26.92%CaO, 18.07%MgO, 1.91%S, 0.38%Zn, 0.05%Pb) is used for the method for preparing magnesium pellets, comprising the following steps:

[0031] S1: Use a jaw crusher and a dry ball mill to crush and grind the lead-zinc waste rock in sequence, and the -0.074mm content of the lead-zinc waste rock after fine grinding is 85%.

[0032] S2: High magnesium powder (82.53% MgO) is dry-type ball milled to -0.074mm content of 83.60%.

[0033] S3: Iron concentrate is hematite concentrate (64.53% Fe, 0.67% FeO, 1.28% SiO 2 , 0.086% CaO, 0.055% MgO, 0.014% S), magnetite concentrate A (64.67% Fe, 26.94% FeO, 8.30% SiO 2 , 0.23% CaO, 0.41% MgO, 0.006% S), magnetite concentrate B (66.16% Fe, 24.15% FeO, 3.49% SiO 2 , 0.52% CaO, 0.46% MgO, 0.083% S) and magnetite concentrate C (69.05% Fe, 28.68% FeO, 1.40% SiO 2 , 0.45% CaO, 0.68% MgO, the mixed iron concentrate of 0.160% S) composition; The hematite concentrate powder, magnetite concentrate A, mag...

Embodiment 2

[0037] A kind of lead-zinc ore waste rock (27.06%CaO, 18.15%MgO, 1.43%S, 0.29%Zn, 0.1%Pb) is used for the method for preparing magnesia pellets, comprising the following steps:

[0038] S1: Use a jaw crusher and a dry ball mill to crush and grind the lead-zinc waste rock in sequence, and the -0.074mm content of the lead-zinc waste rock after fine grinding is 85%.

[0039] S2: High-magnesium powder (82.53% MgO) and limestone (52.97% CaO) are dry ball milled to a content of 83.60% at -0.074mm.

[0040] S3: Iron concentrate is hematite concentrate (65.23% Fe, 0.91% FeO, 1.23% SiO 2 , 0.004% CaO, 0.039% MgO, 0.007% S), magnetite concentrate (69.65% Fe, 28.02% FeO, 1.57% SiO 2 , 0.11% CaO, 0.15% MgO, 0.023% S) and sulfuric acid slag (63.07% Fe, 3.16% SiO 2 , 0.73% CaO, 0.23% MgO) mixed iron concentrate, hematite concentrate powder, magnetite concentrate, and sulfuric acid slag are mixed in a ratio of 40:40:20, and water is added to adjust the water content of the mixed concentrat...

Embodiment 3

[0044] A kind of lead-zinc ore waste rock (27.06%CaO, 18.15%MgO, 1.43%S, 0.29%Zn, 0.1%Pb) is used for the method for preparing magnesia pellets, comprising the following steps:

[0045] S1: Use a jaw crusher and a dry ball mill to crush and grind the lead-zinc waste rock in sequence, and the -0.074mm content of the lead-zinc waste rock after fine grinding is 85%.

[0046] S2: High-magnesium powder (82.53% MgO) and limestone (52.97% CaO) are dry ball milled to a content of 83.60% at -0.074mm.

[0047] S3: Iron concentrate is hematite concentrate (65.23% Fe, 0.91% FeO, 1.23% SiO 2 , 0.004% CaO, 0.039% MgO, 0.007% S), magnetite concentrate (69.65% Fe, 28.02% FeO, 1.57% SiO 2 , 0.11% CaO, 0.15% MgO, 0.023% S) and sulfuric acid slag (63.07% Fe, 3.16% SiO 2 , 0.73% CaO, 0.23% MgO) mixed iron concentrate, hematite concentrate powder, magnetite concentrate, and sulfuric acid slag are mixed in a ratio of 40:40:20, and water is added to adjust the water content of the mixed concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com