Patents

Literature

40results about How to "Mature process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing aromatic hydrocarbon rubber filling oil

InactiveCN1752182ASolve the shortage of productionMature processTar working-up by distillationOil processingTar

A process for preparing the arylhydrocarbon-type filling oil for rubber includes such steps as mixing tar fraction with H2, hydrogenating reaction on hydromodifying catalyst Mo-Ni-P for removing S, N, colloid and asphalt from tar fraction, separating out H2, dry gas, H2S, NH4 and liquefied gas to obtain liquid, fractionating, and cutting.

Owner:CHINA PETROCHEMICAL CORP +1

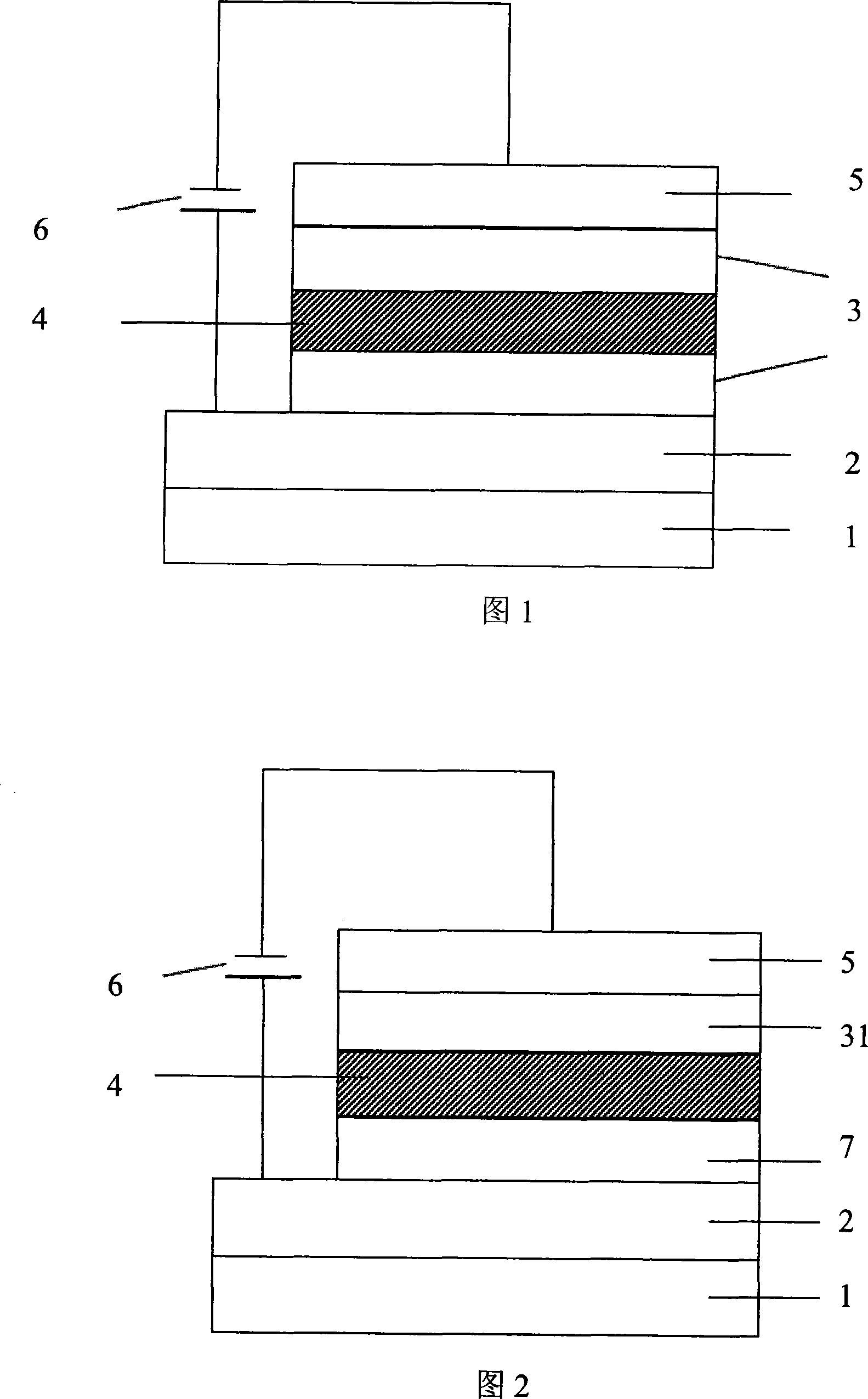

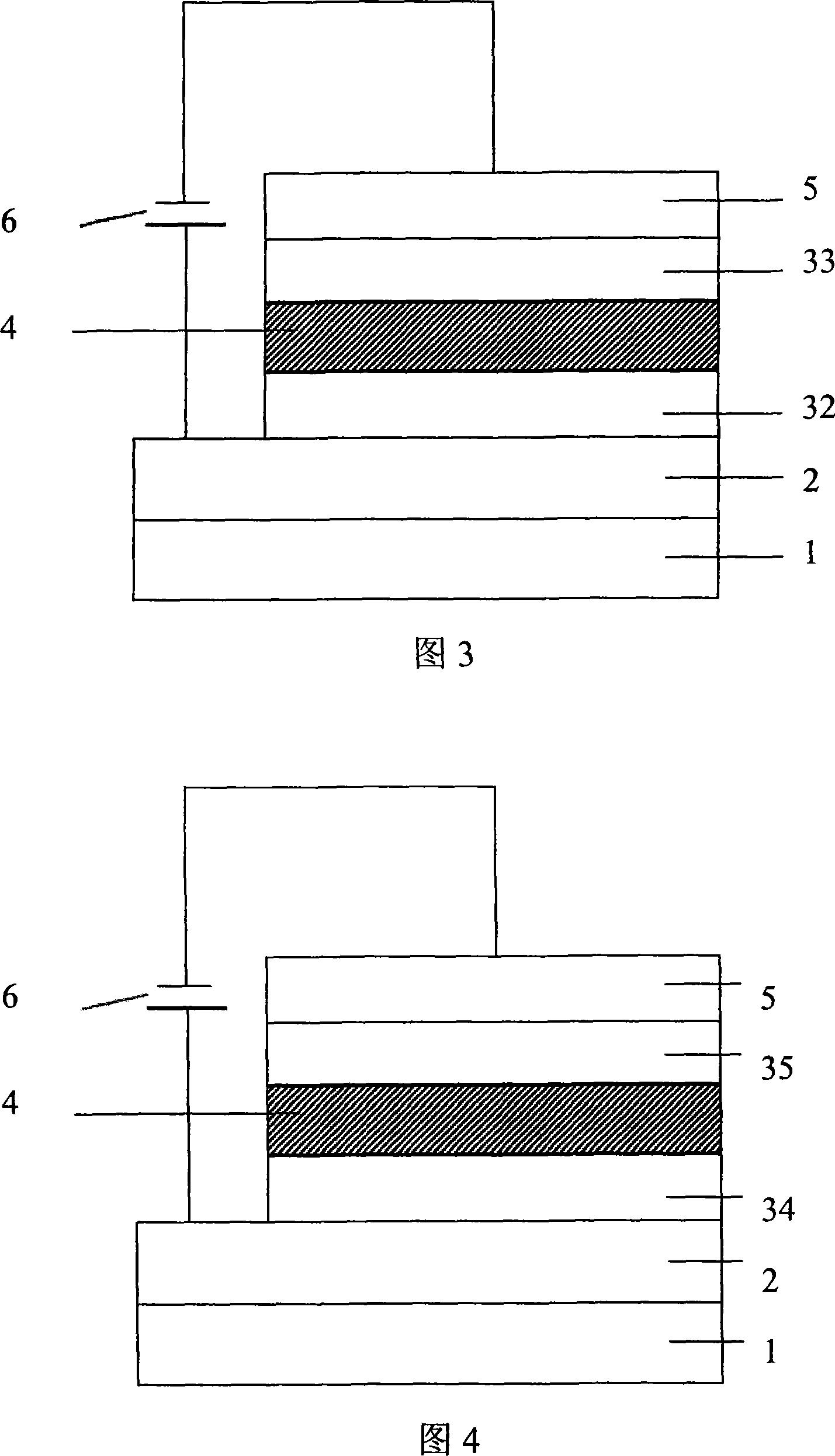

Novel electroluminescent device and method for producing the same

InactiveCN101114699AWide range of choicesMature processSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceLight driven

The invention discloses a novel organic electroluminescent device, comprising a conducting base plate or a substrate, an anode layer and a cathode layer, an electrode on the surface of the substrate or the conducting base plate and an organic functional layer between the anode layer and the cathode layer which comprises at least a luminescent layer emitting light driven by an additional power, and is characterized in that the organic functional layer further comprises one or more type of a compound regulation layer, an electron transporting layer, a hole-transporting layer and a hole blocking layer, the compound regulation layer is a carrier compound regulation layer which is made by one or more materials of poly-N-vinylcarbazole, BCP, two(2-methyl-8-quinoline acid radical complex)three phenyl silanol aluminum(III), two (2-methyl-8-quinoline acid radical complex)4-phenol aluminum(III) and two(2-methyl-8-quinoline acid radical complex)4-phenyl-based phenol aluminum (III).

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

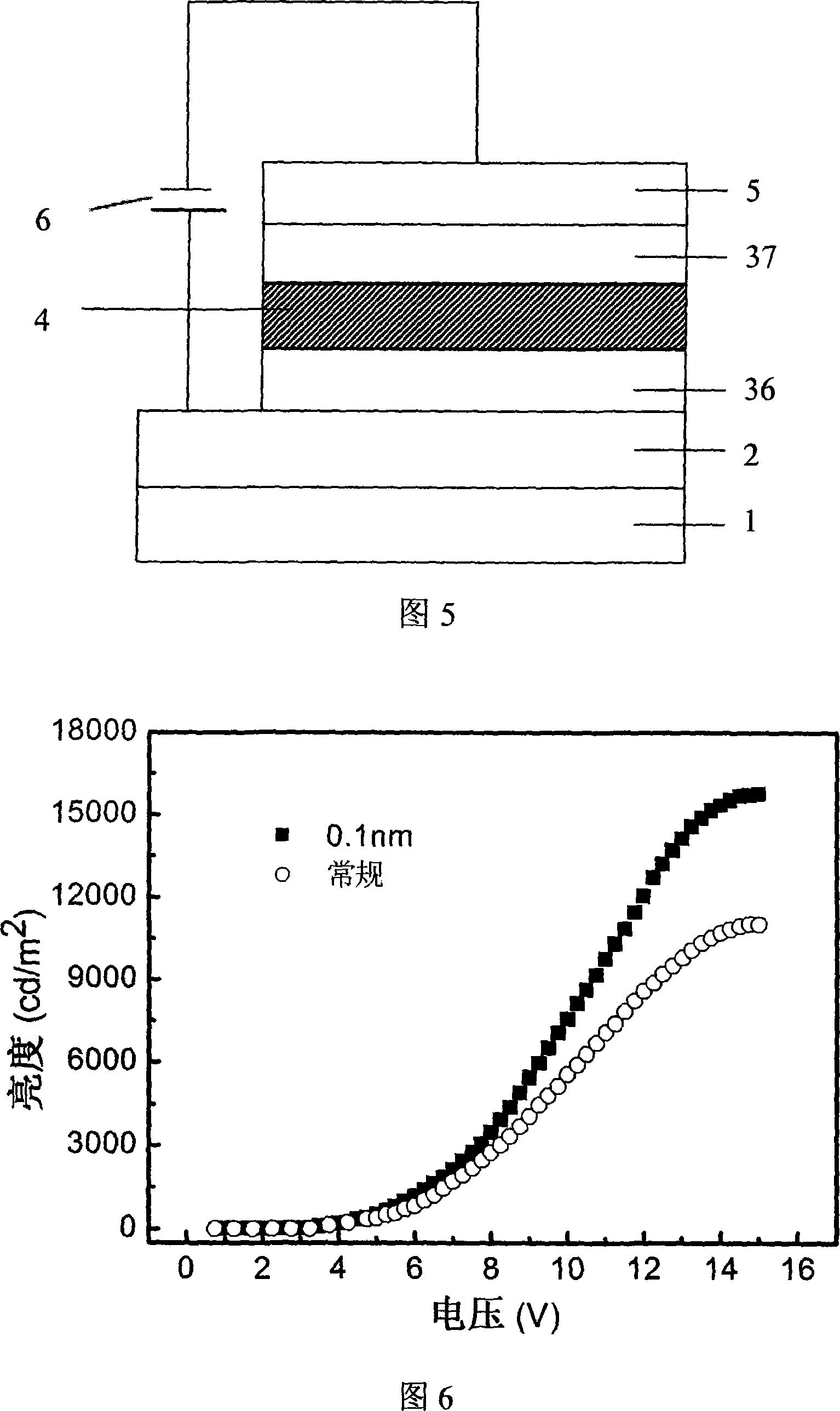

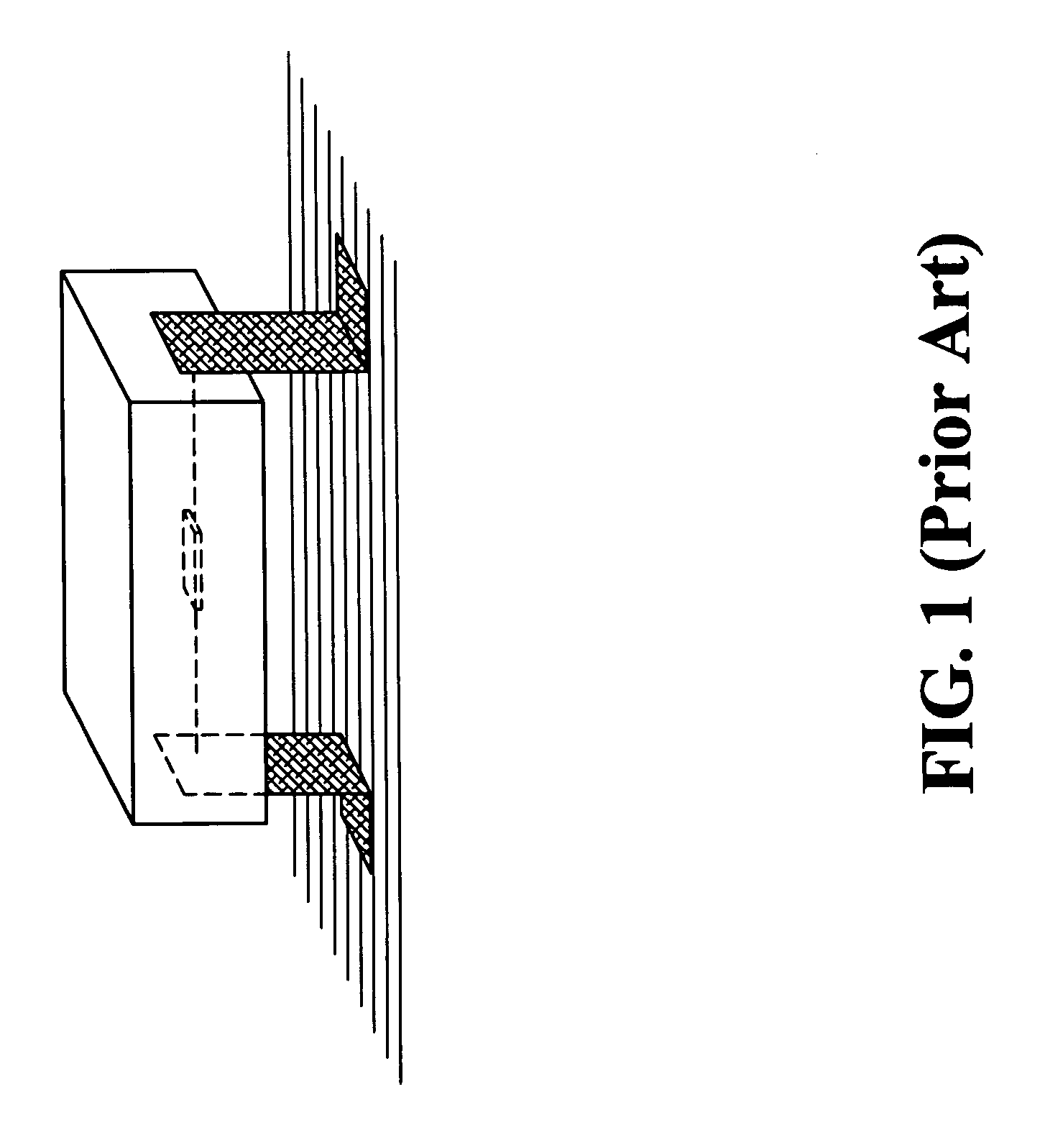

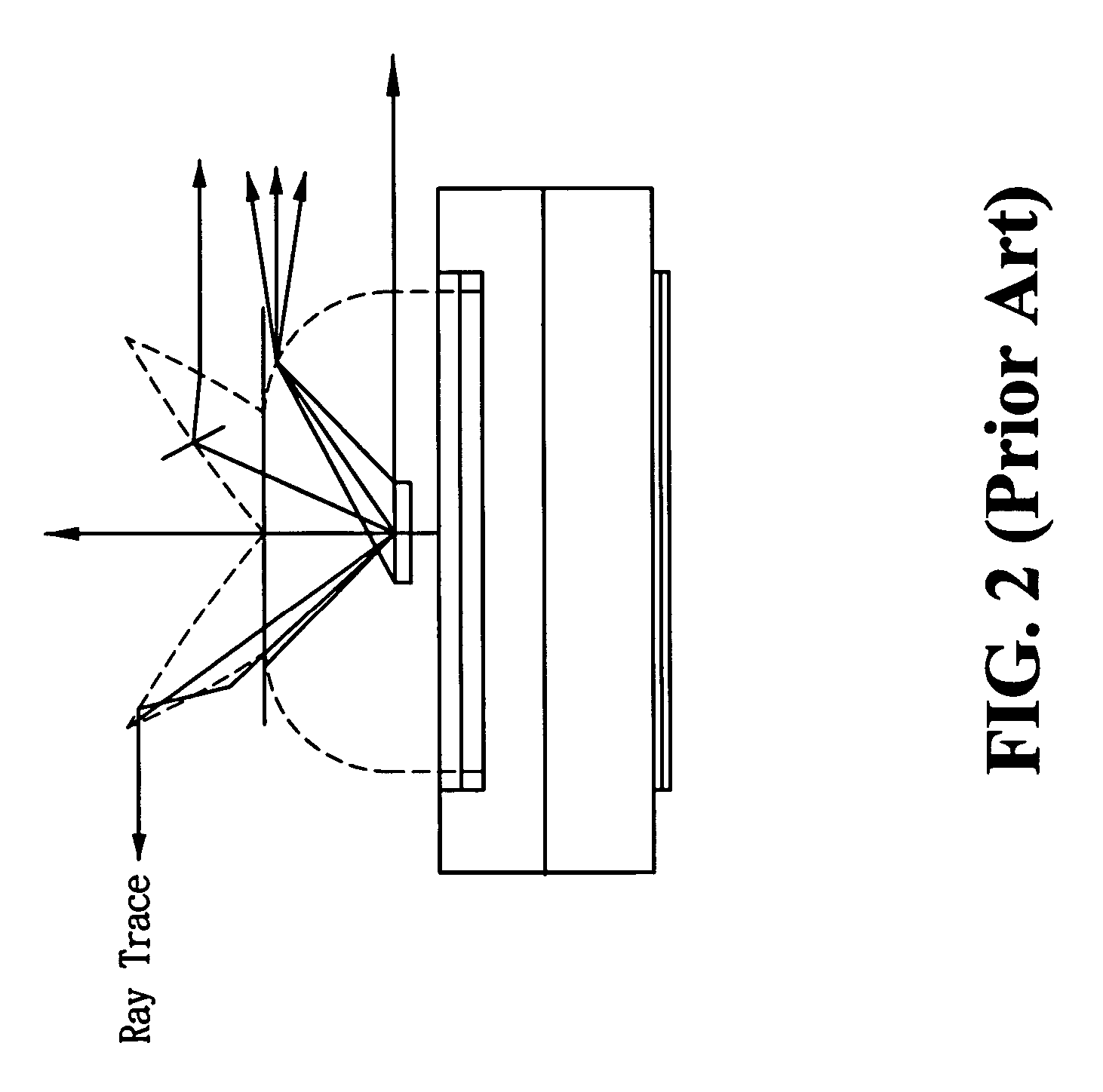

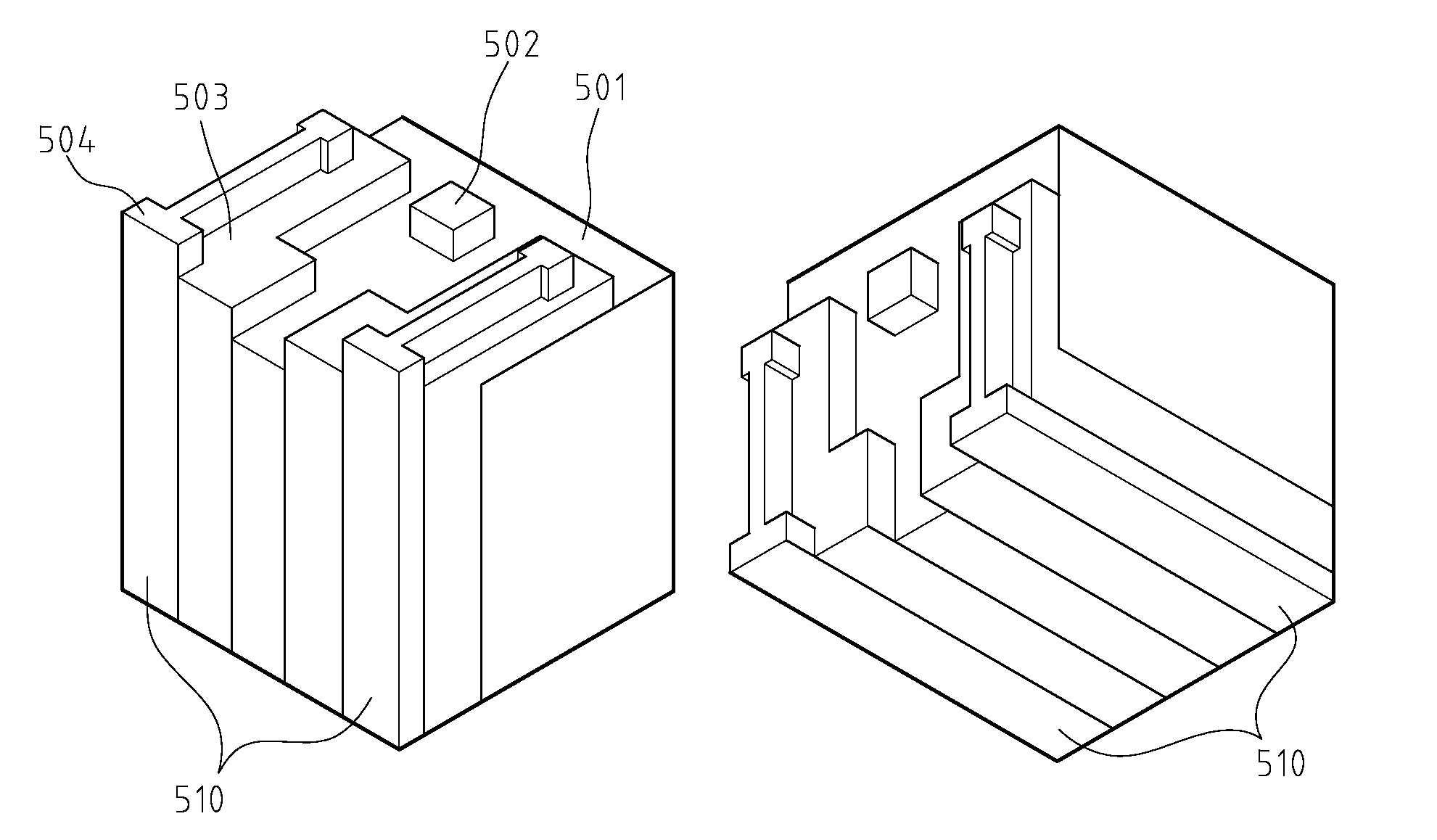

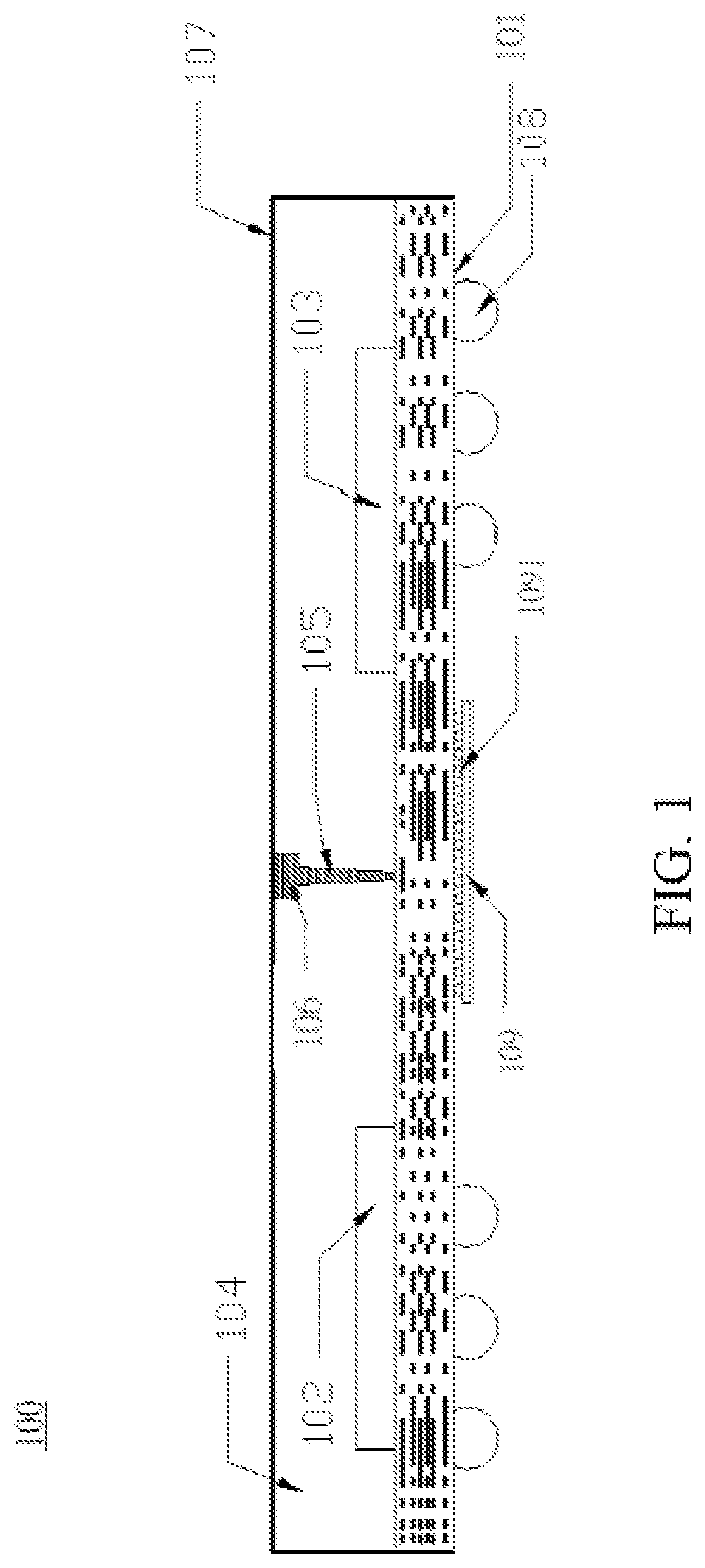

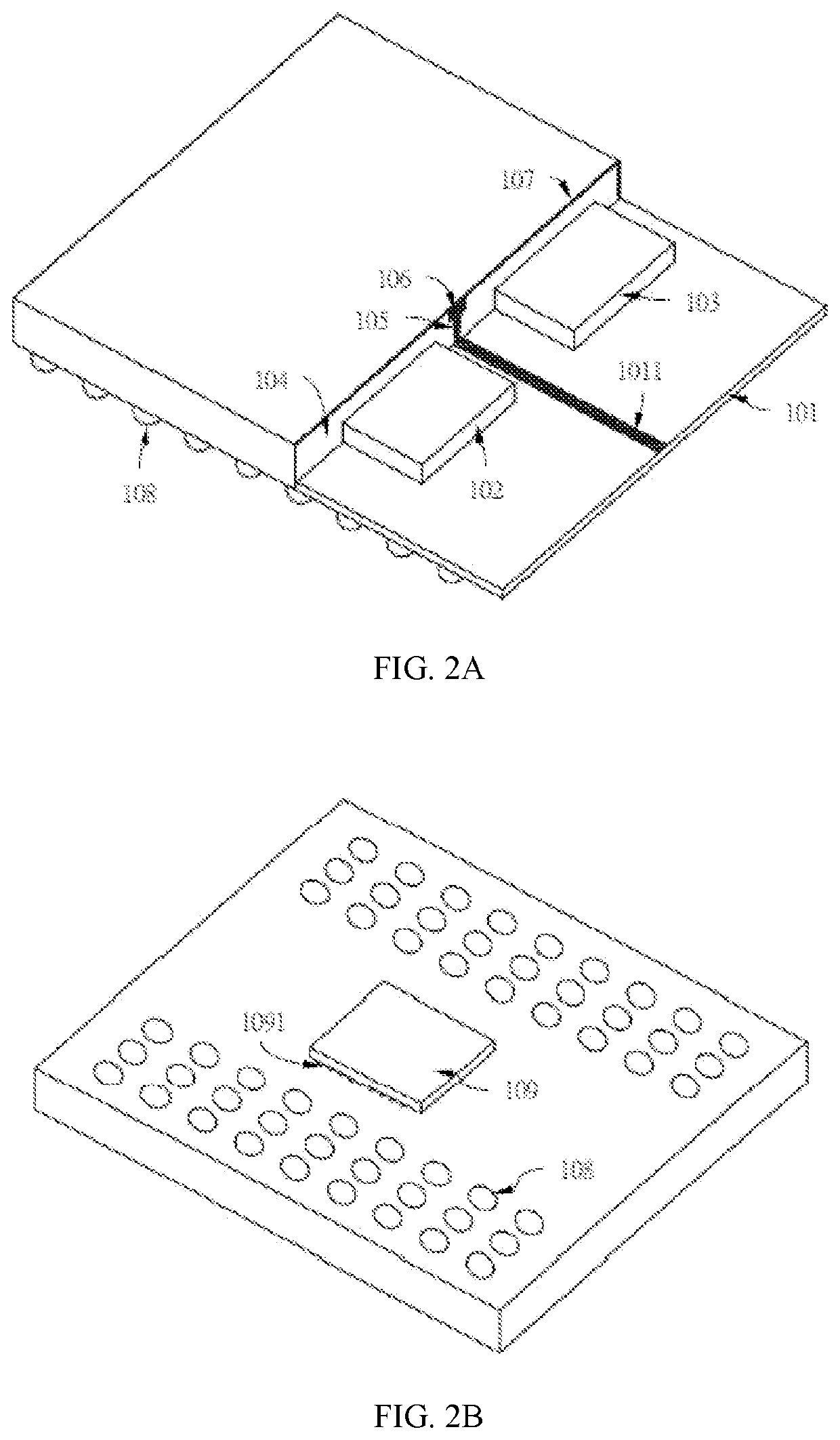

Packaging of SMD light emitting diodes

InactiveUS20060289888A1Easy to mass produceOvercomes drawbackSolid-state devicesSemiconductor devicesEngineeringDielectric layer

An SMD LED package with superior thermal dissipation capability is provided. The SMD LED package comprises a supporting block with circuit patterns and at least one LED attached to the supporting block. Wherein, circuit patterns of holes / vias, insulating layers, and conducting traces / pads are formed on and in the supporting block. The SMD LED packages can be further assembled to from a light module that allows emitted lights to travel in parallel with the mounting surface. The SMD manufacturing process is a mature production process and thus easy for mass production. Single or plural LED chips are mounted on a thermal conducting block that is disposed with patterns of conducting traces / pads and isolating dielectric layers. The side emitting characteristics of the present invention offers the advantage of reflecting and mixing the emitted lights to meet the desired chromaticity.

Owner:IND TECH RES INST

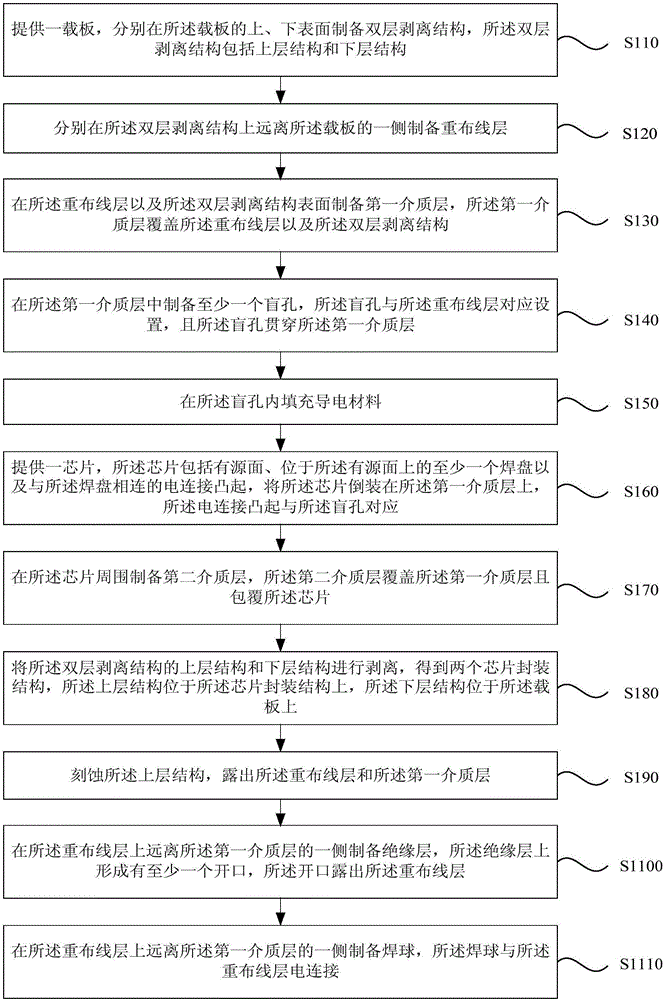

Chip packaging structure and preparation method thereof

InactiveCN106531642AAvoid risks during processingReduce riskSemiconductor/solid-state device detailsSolid-state devicesOperabilityEngineering

The invention discloses a chip packaging structure and a preparation method thereof. The preparation method comprises the following steps: providing a support plate, and preparing double-layer peeling structures on the upper surface and the lower surface of the support plate; preparing a rewiring layer on the side, away from the support plate, of each double-layer peeling structure; preparing first dielectric layers on each rewiring layer and the surface of each double-layer peeling structure; preparing at least one blind hole in each first dielectric layer; filling a conducting material in the blind holes; providing a chip, and arranging the chip on each first dielectric layer; preparing a second dielectric layer on the periphery of each chip, wherein each first dielectric layer is covered with the corresponding second dielectric layer, and each chip is wrapped by the corresponding second dielectric layer; peeling off the double-layer peeling structures; etching an upper-layer structure of each double-layer peeling structure so as to expose the corresponding rewiring layer and the corresponding first dielectric layer; and preparing a welded ball on the side, away from each first dielectric layer, of the corresponding rewiring layer, wherein each welded ball is electrically connected with the corresponding rewiring layer. To sum up, the preparation method is simple, high in operability and low in cost, and can avoid chip damage; and moreover, preparation technology is carried out on two sides of the support plate simultaneously, so that the efficiency is high, and warping is avoided.

Owner:NAT CENT FOR ADVANCED PACKAGING

Two-junction laser battery epitaxial layer and preparation method thereof

InactiveCN106653925ATotal current dropReduce power lossFinal product manufacturePhotovoltaic energy generationElectrical resistance and conductanceTotal current

The invention relates to a two-junction laser battery epitaxial layer and a preparation method thereof; the two-junction laser battery epitaxial layer comprises a GaAs buffer layer, a first tunnel junction, a first GaAs cell, a second tunnel junction, a second GaAs cell and a cap layer arranged in order on a GaAs substrate from bottom to top; the preparation method comprises the following steps: using a metal organic chemical vapor deposition (CVD) technology to deposit the GaAs buffer layer on the GaAs substrate; growing the first tunnel junction, the first GaAs sub cell, the second tunnel junction, the second GaAs sub cell and the cap layer in order on the GaAs buffer layer; the two-junction laser battery epitaxial layer uses the two sub-cells connected in series to reduce the total current, thus reducing power loss caused by cascading resistors, and improving conversion efficiency; the battery preparation method uses the metal organic chemical vapor deposition (CVD) technology, thus precisely controlling the growth process, and forming the crystal with good quality.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

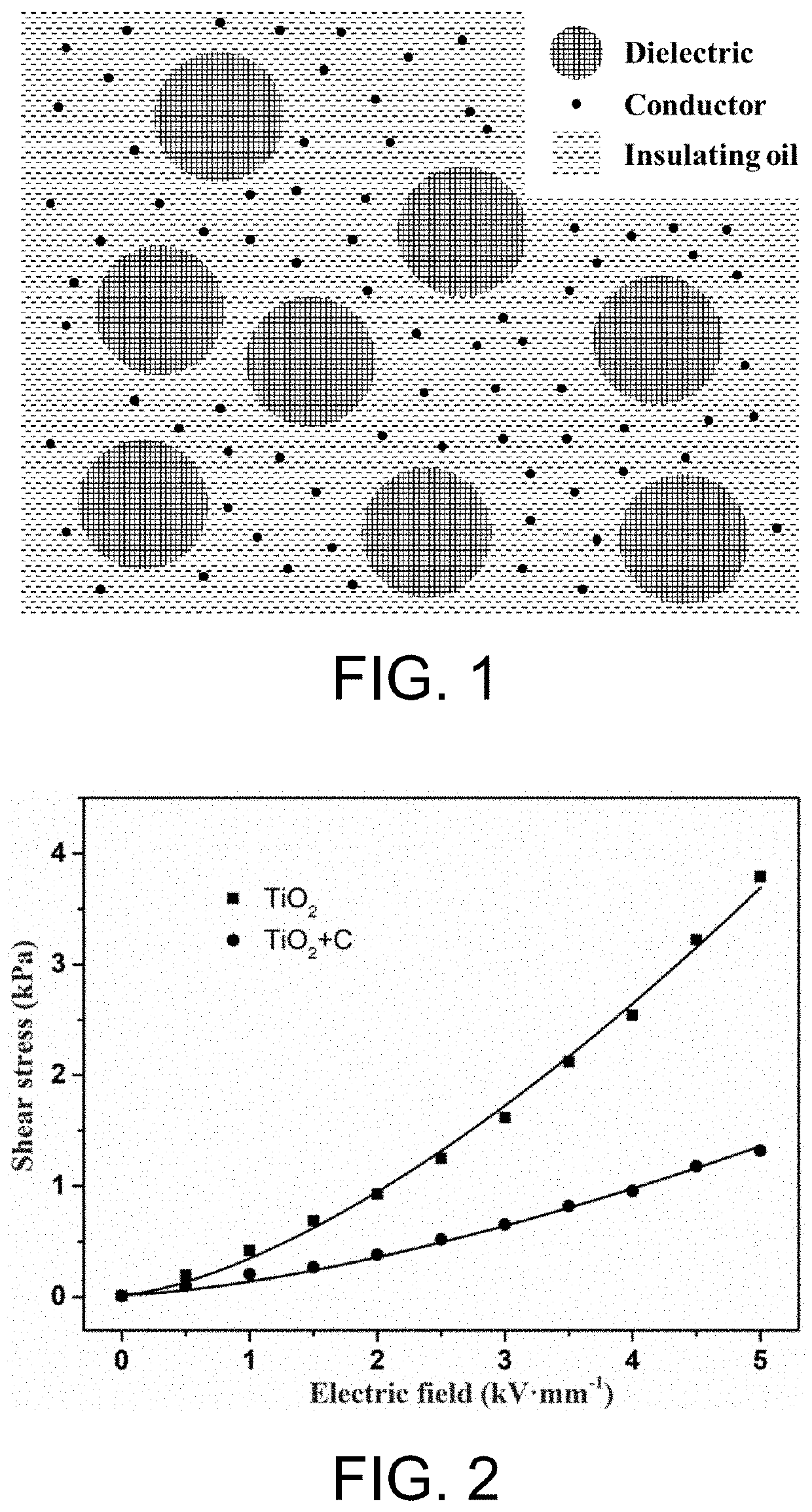

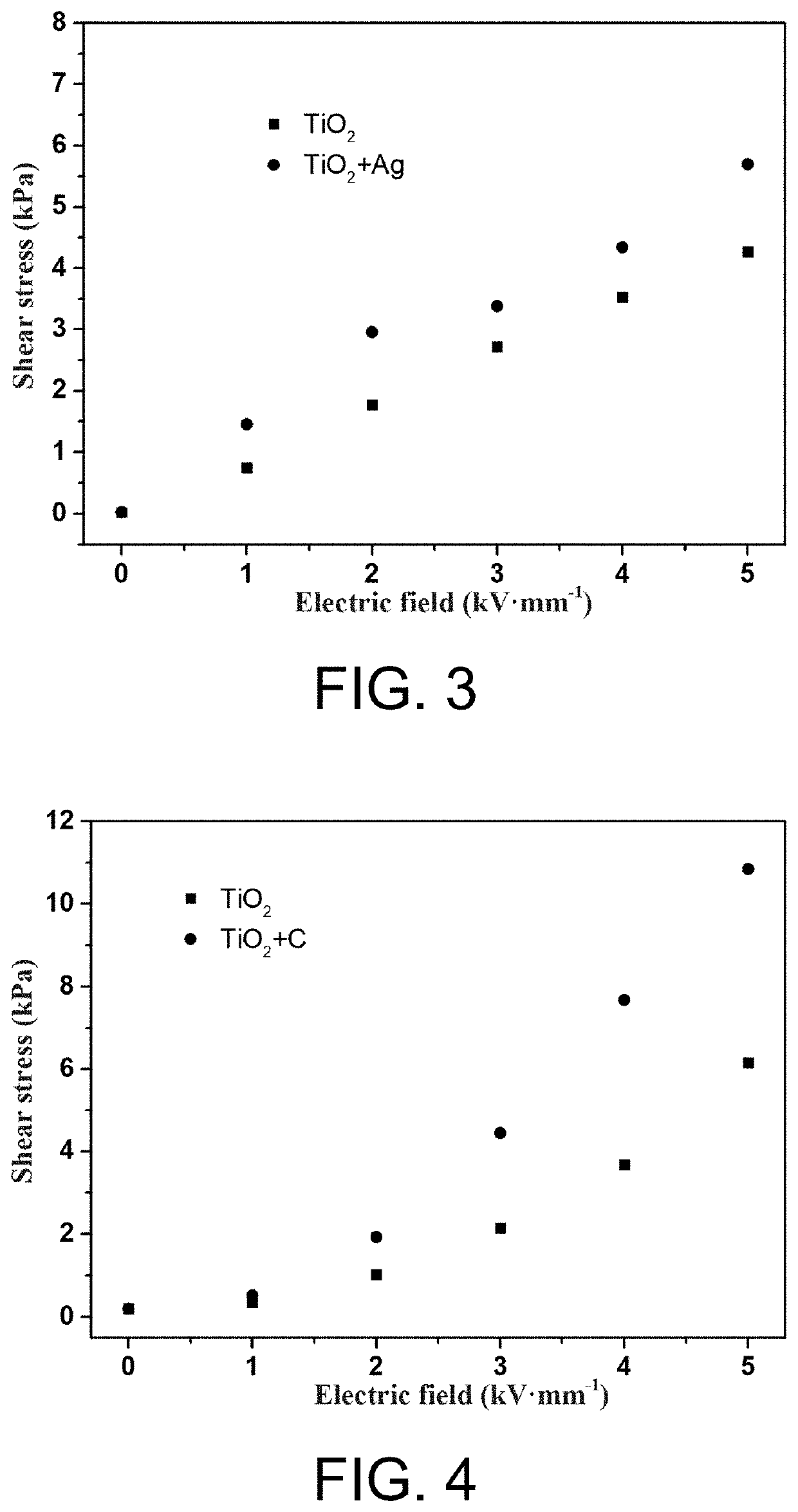

Electrorheological fluid

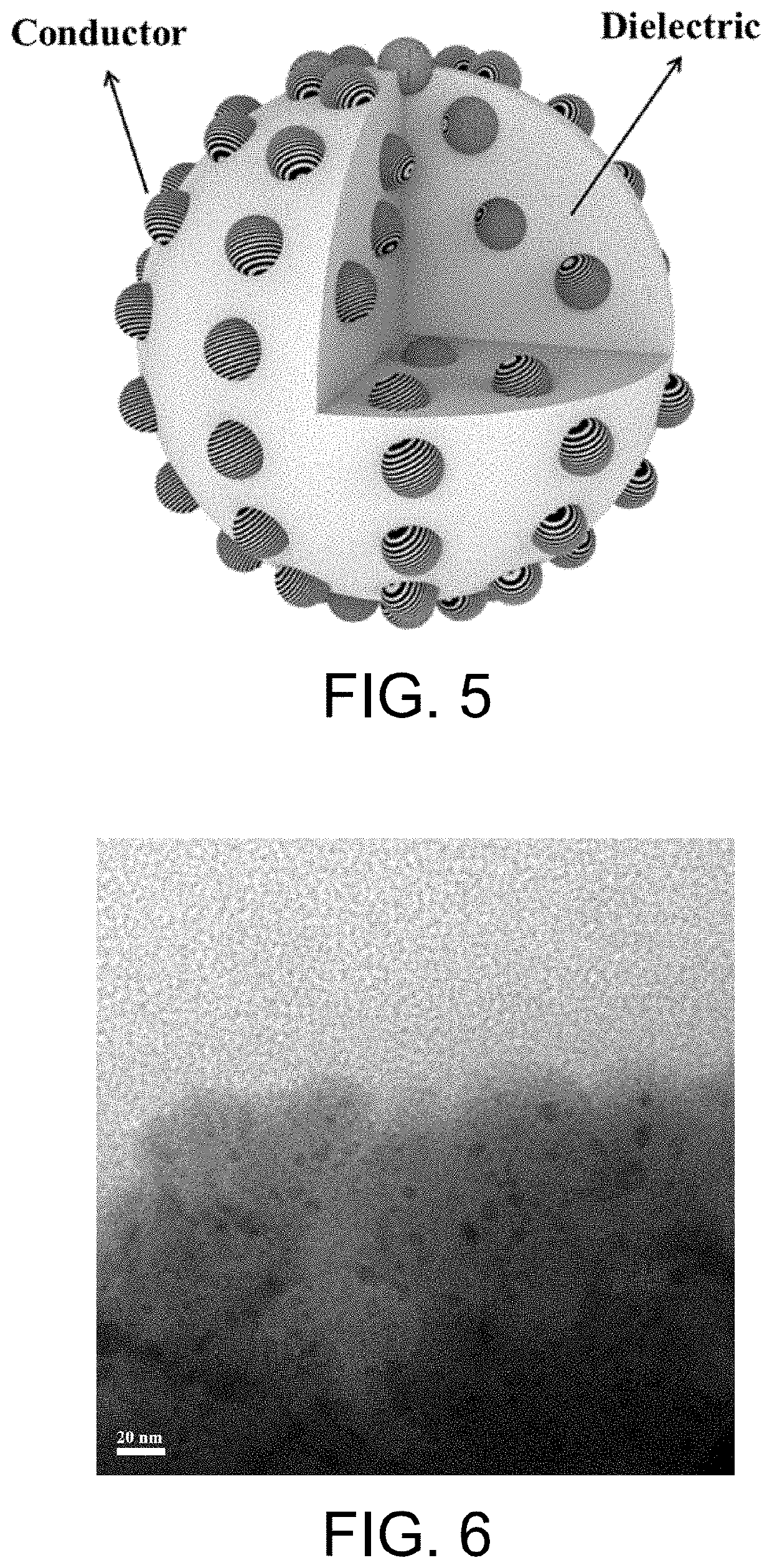

ActiveUS20200024543A1Increase shear stressSmall currentThickenersBase-materialsDielectricThermodynamics

The present invention provides an electrorheological fluid, which includes a dielectric particle, a conductor particle and insulating oil, and the dielectric particle is evenly dispersed in the insulating oil; wherein the conductor particle is evenly dispersed in the insulating oil or inlaid in an interior and on a surface of the dielectric particle. The electrorheological fluid has the advantages of high shear stress, long service life, good temperature stability and small leakage current.

Owner:SUN YAT SEN UNIV

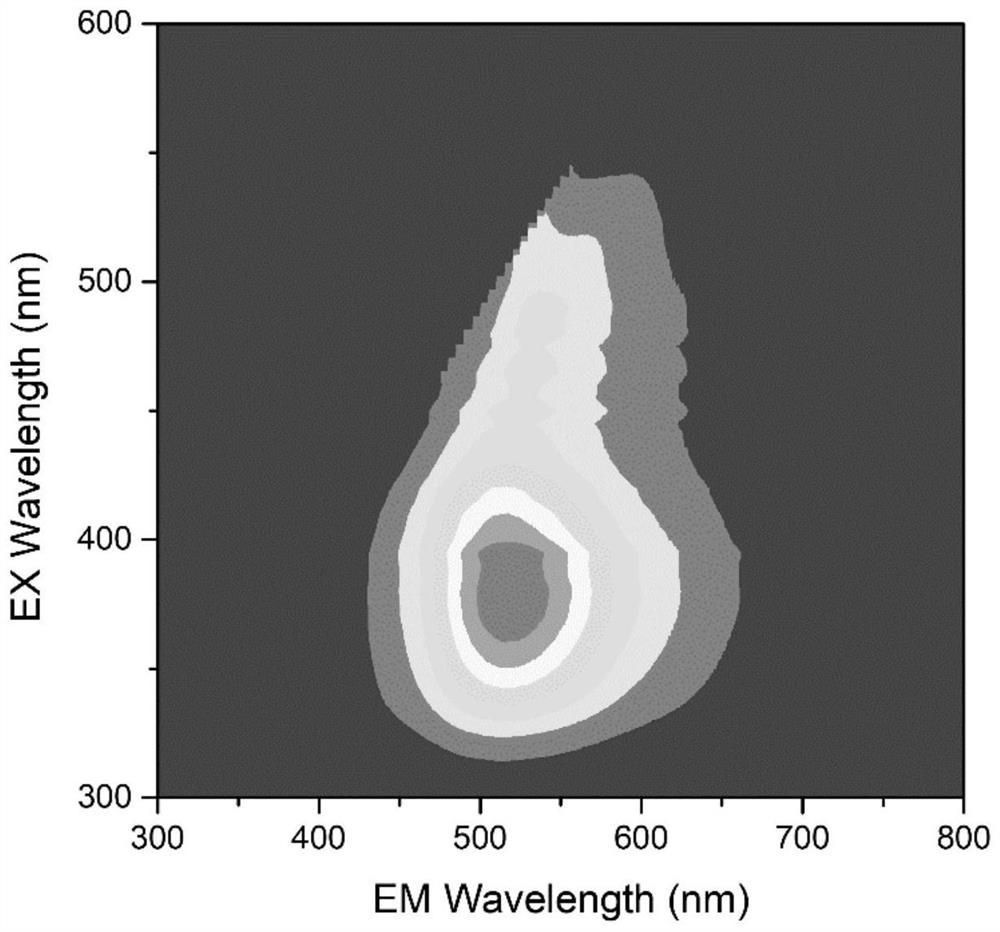

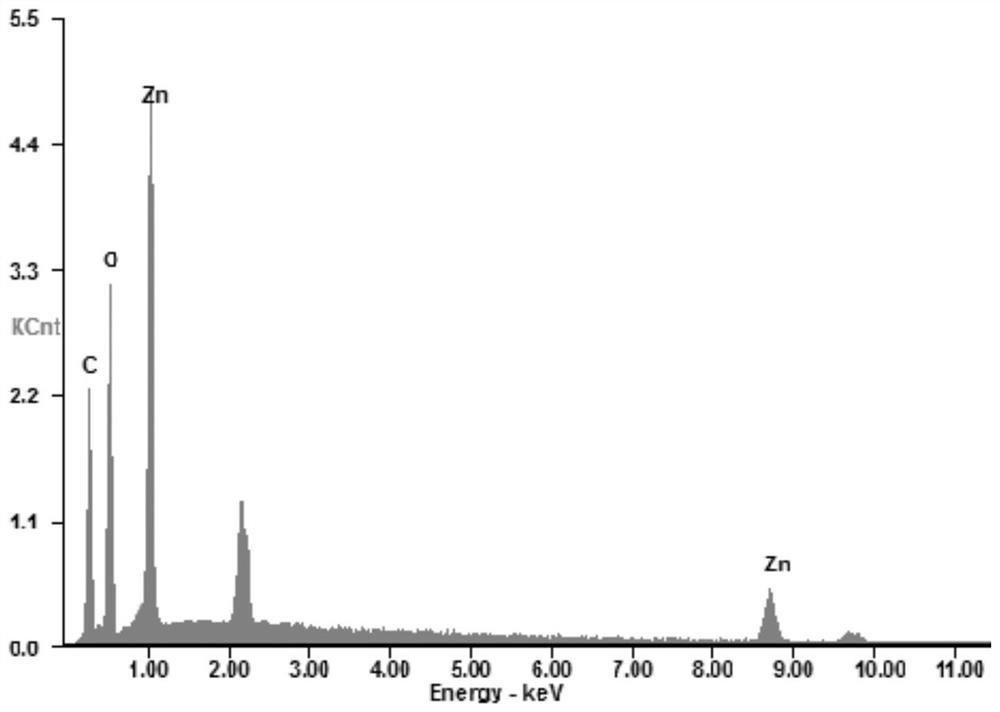

Fluorescent antibacterial polycarbonate composite material as well as preparation method and application thereof

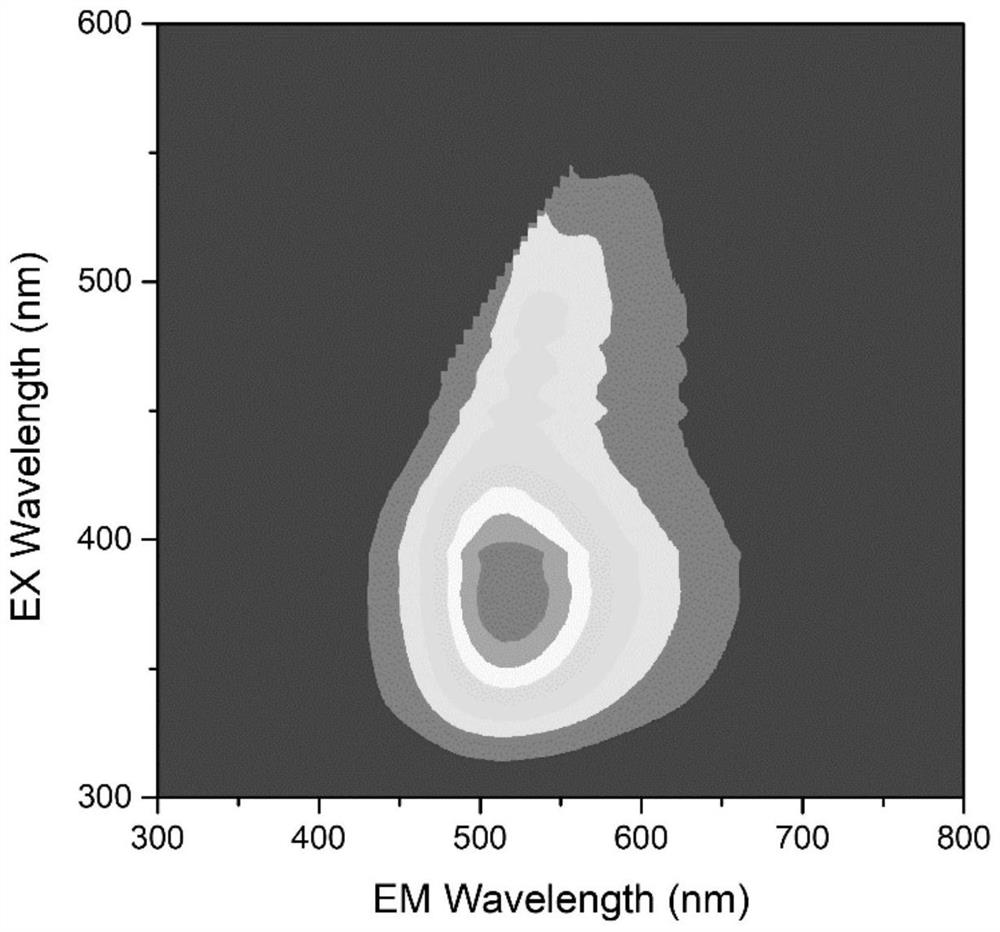

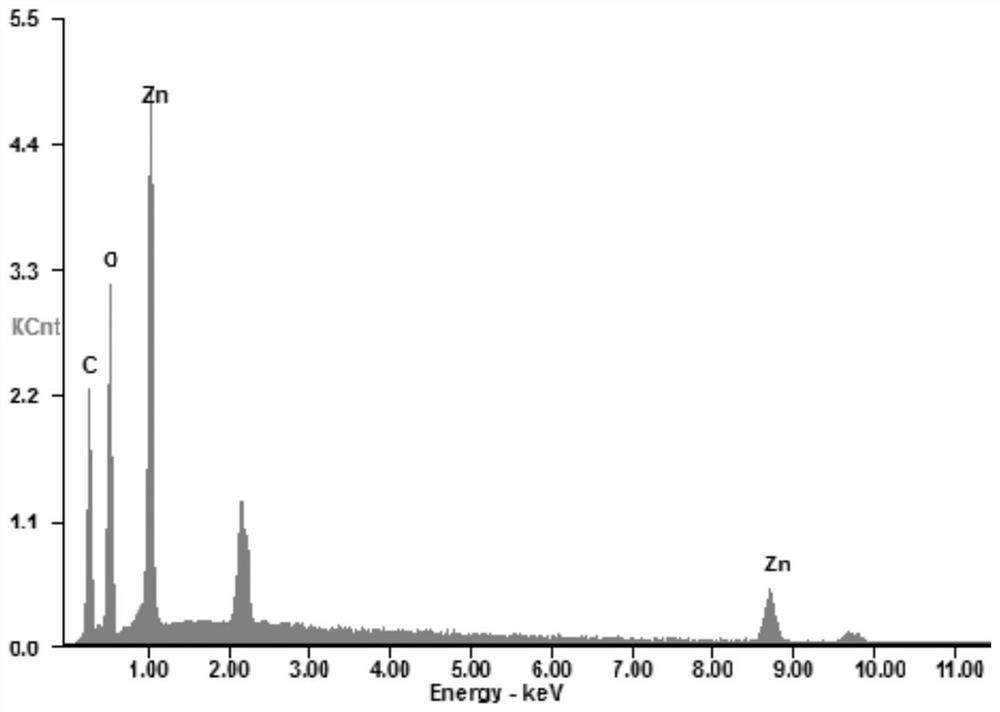

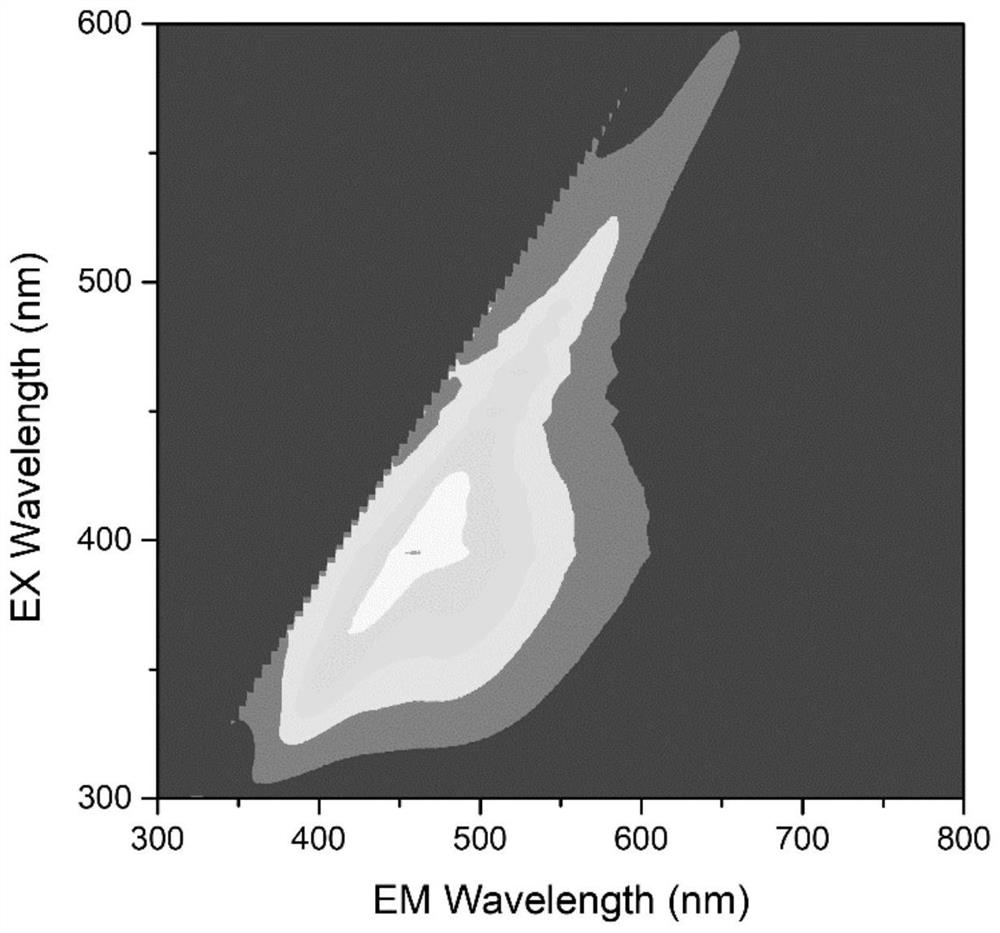

ActiveCN111793340ARaw materials are easy to getMature industrial production processLuminescent compositionsEscherichia coliFluorescence

The invention relates to a fluorescent antibacterial polypropylene material, and a preparation method and application thereof, and belongs to the field of polymer materials. The fluorescent antibacterial polycarbonate composite material comprises blended polycarbonate resin and a fluorescent antibacterial polymer material. The fluorescent antibacterial polymer material accounts for 0.1-20 parts byweight of 100 parts by weight of the polycarbonate resin. The fluorescent antibacterial polymer material is a maleic anhydride copolymer zinc salt derivative. The excitation light range of the fluorescent antibacterial polycarbonate composite material is 300-600 nm, and the emission light range is 300-700 nm. The antibacterial rates of the fluorescent antibacterial polycarbonate composite material to escherichia coli and staphylococcus aureus are both greater than 99%. The fluorescent antibacterial polycarbonate composite material is low in price of related raw materials, simple in preparation method and low in environmental pollution. The fluorescent antibacterial polycarbonate composite material is excellent in fluorescence property, high in safety, lasting in antibacterial effect and suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing aromatic hydrocarbon rubber filling oil

InactiveCN1331985CSolve the shortage of productionMature processTar working-up by distillationOil processingTar

Owner:CHINA PETROCHEMICAL CORP +1

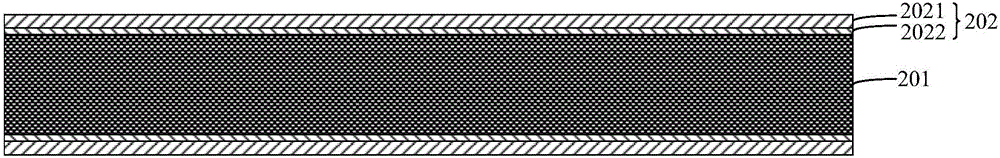

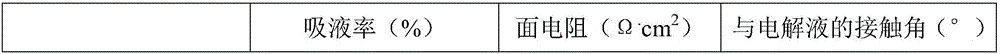

High-wettability lithium-ion battery separator and preparation method thereof

InactiveCN106654127AImprove electrochemical performanceImprove wettabilityCell component detailsPolyolefinSolvent

The invention relates to the field of lithium-ion batteries, and discloses a high-wettability lithium-ion battery separator and a preparation method thereof. The separator contains an adhesive component which has high wettability on a lithium-ion battery electrolyte in the surface and the inside. The preparation method comprises the following steps of (1) dissolving an adhesive material into an oily solvent to obtain a mixture I; and (2) coating the surface of a polyolefin separator with the mixture I, immersing the solvent into an internal gap of the separator and then drying to obtain the lithium-ion battery separator with high wettability on the electrolyte. The prepared separator is high in wettability on the electrolyte, low in cost and simple in processing procedure.

Owner:HEFEI XINGYUAN NEW ENERGY MATERIAL CO LTD

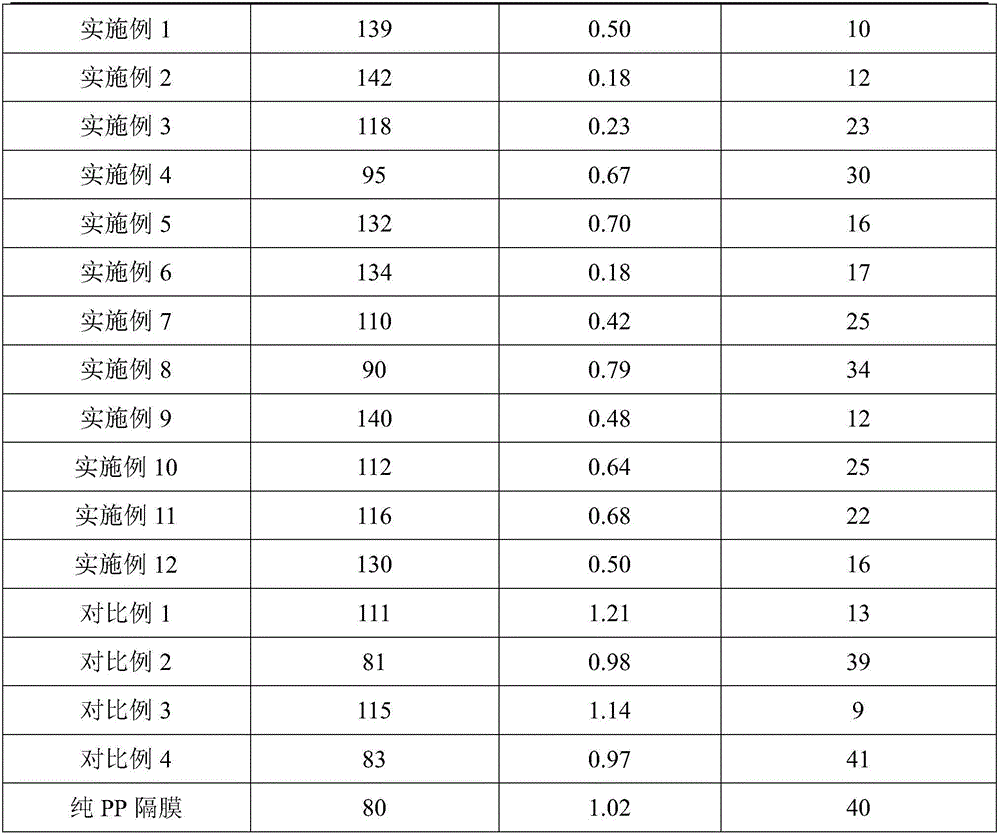

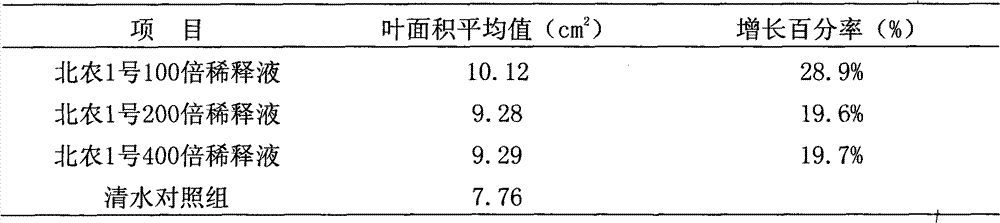

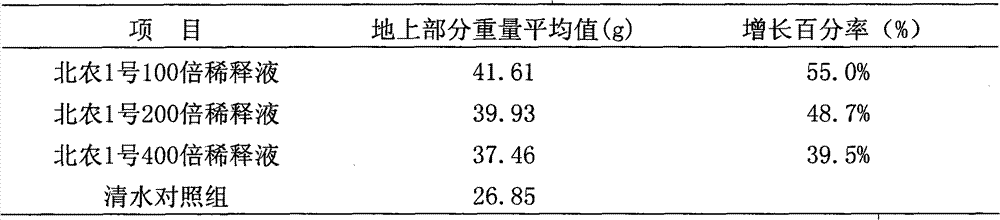

Pesticidal foliage fertilizer mixed with plant growth factors and preparation method thereof

InactiveCN101941872BIncrease productionBeneficial sustainable productionFertilizer mixtures1-Aminocyclopropane-1-carboxylic acidCarboxylic acid

The invention discloses a pesticidal foliage fertilizer, which is prepared by grinding and uniformly mixing gibberellin 3, heteroauxin, brassinolide, abscisic acid, jasmonic acid, zeatin, salicylic acid, 1-aminocyclopropane-carboxylic acid. The fertilizer is a novel phytosterol foliage fertilizer with advantages of high efficiency, no toxicity and environmental friendliness, can promote the growth of plants by over 10 percent, and has no environmental pollution.

Owner:BEIJING UNIV OF AGRI

Packaging of SMD light emitting diodes

InactiveUS7339196B2Improve rendering capabilitiesExcellent characteristicsSolid-state devicesSemiconductor devicesComputer moduleEngineering

An SMD LED package with superior thermal dissipation capability is provided. The SMD LED package comprises a supporting block with circuit patterns and at least one LED attached to the supporting block. Wherein, circuit patterns of holes / vias, insulating layers, and conducting traces / pads are formed on and in the supporting block. The SMD LED packages can be further assembled to form a light module that allows emitted lights to travel in parallel with the mounting surface. The SMD manufacturing process is a mature production process and thus easy for mass production. Single or plural LED chips are mounted on a thermal conducting block that is disposed with patterns of conducting traces / pads and isolating dielectric layers. The side emitting characteristics of the present invention offers the advantage of reflecting and mixing the emitted lights to meet the desired chromaticity.

Owner:IND TECH RES INST

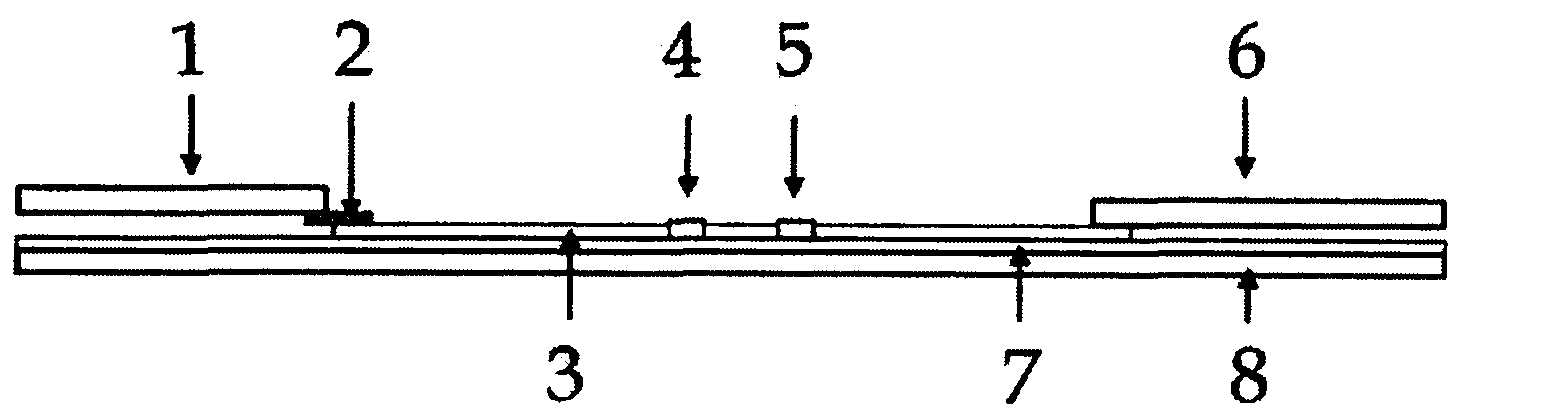

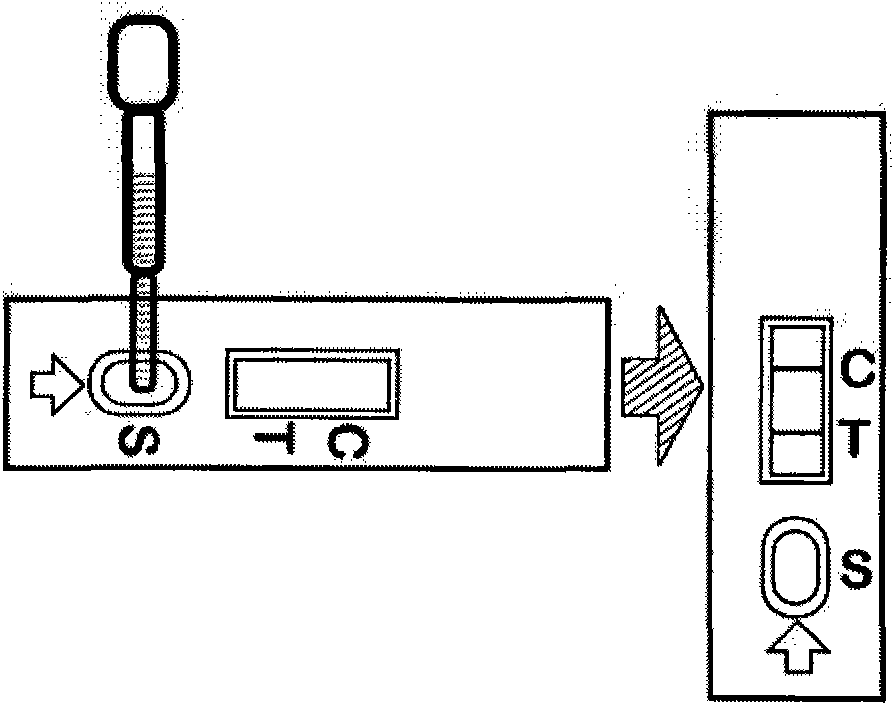

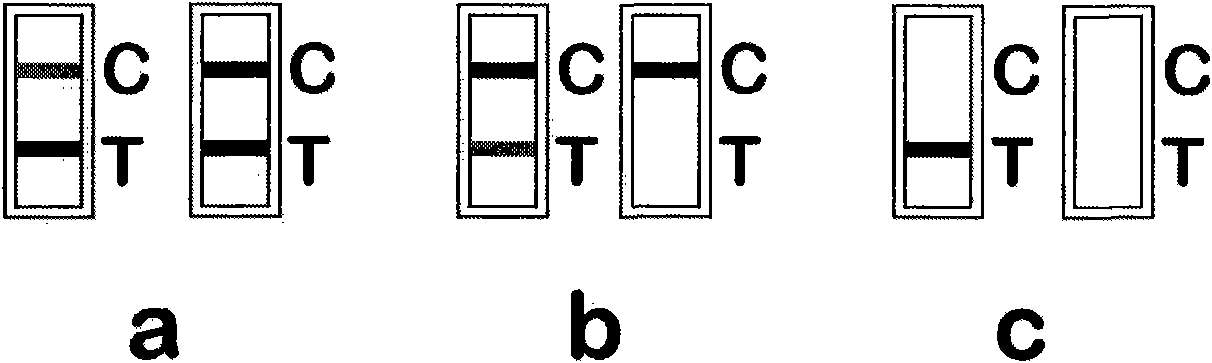

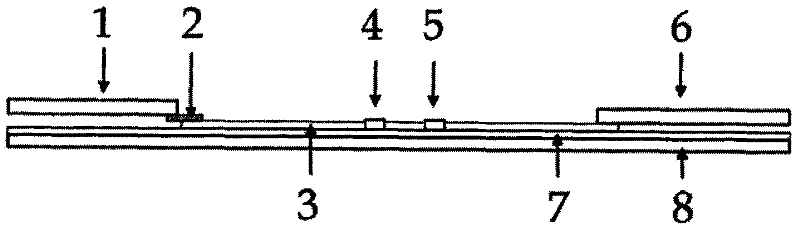

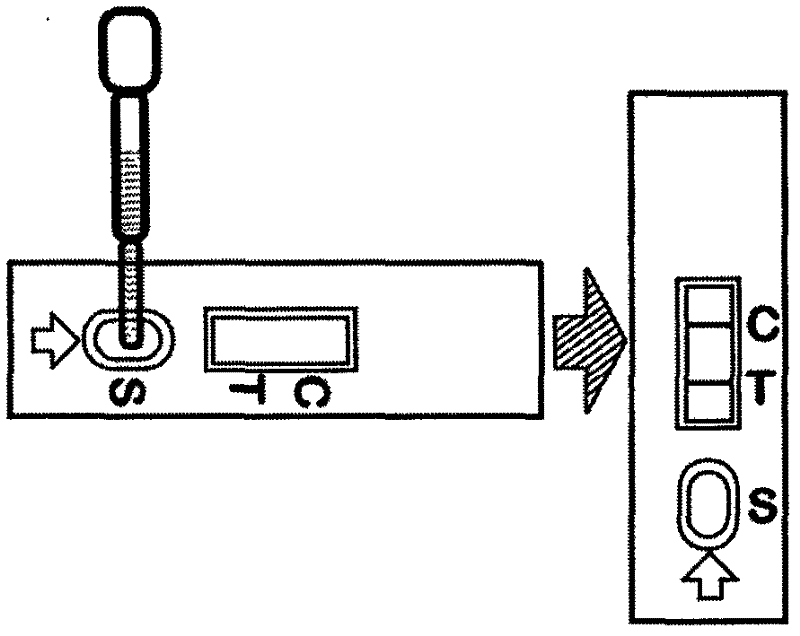

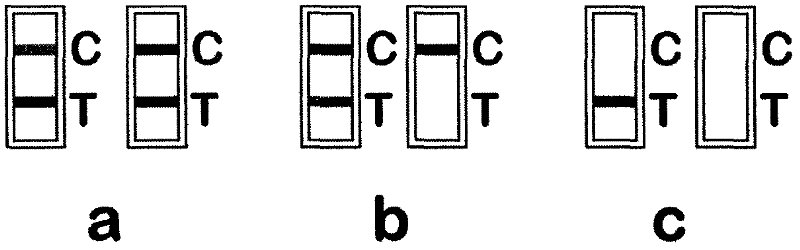

Preparation method of reagent plate for detecting chloramphenicol in cosmetics

InactiveCN101858907ALow cross-reactivityStrong specificityMaterial analysisCHLORAMPHENICOL TOXICITYAcarus

The invention relates to a reagent plate for detecting immune colloidal gold of chloramphenicol, which can be used for detecting the chloramphenicol in cosmetics. The reagent plate comprises upper and lower plastic templates and a back lining, wherein a sample pad, a colloidal gold bonding pad, a nitrocellulose membrane and a water absorbing pad are closely attached to the back lining in sequence. A detection line and a quality control line are sequentially sprayed on the nitrocellulose membrane in the direction from the sample pad to the water absorbing pad so as to represent the reaction result in a macroscopic colour. The reagent plate can be used for semi-quantitative visual detection; and the entire operation process takes only 20 to 30 minutes and needs no assistance of expensive experimental facilities; therefore, the reagent plate is favourable for large-scale screening of samples and is suitable for the industry and commerce department and the inspection and quarantine organization to perform large-scale quick detection on the chloramphenicol illegally added in the cosmetics, in particular to the anti-acne and anti-acarus cosmetics.

Owner:杭州南开日新生物技术有限公司

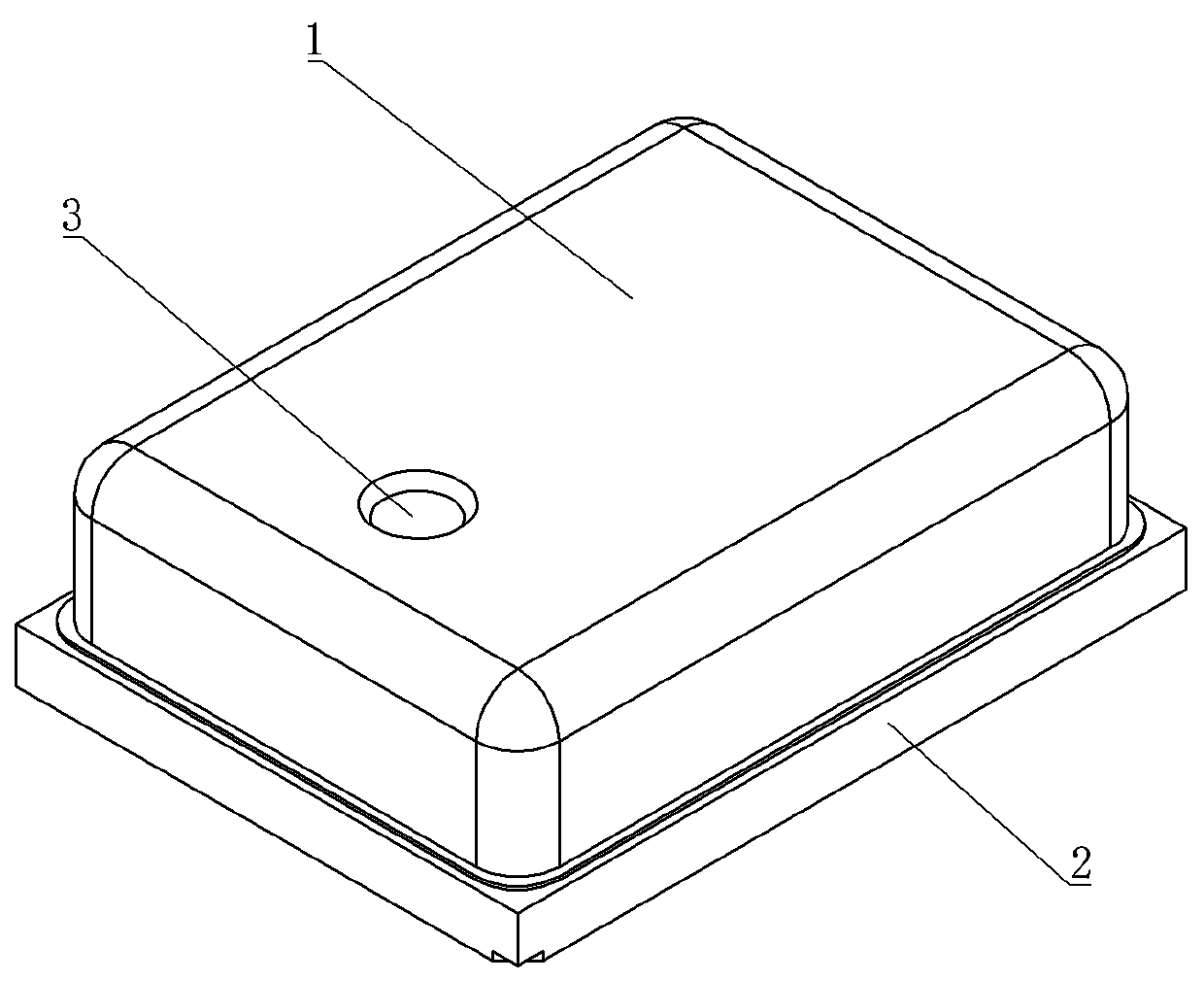

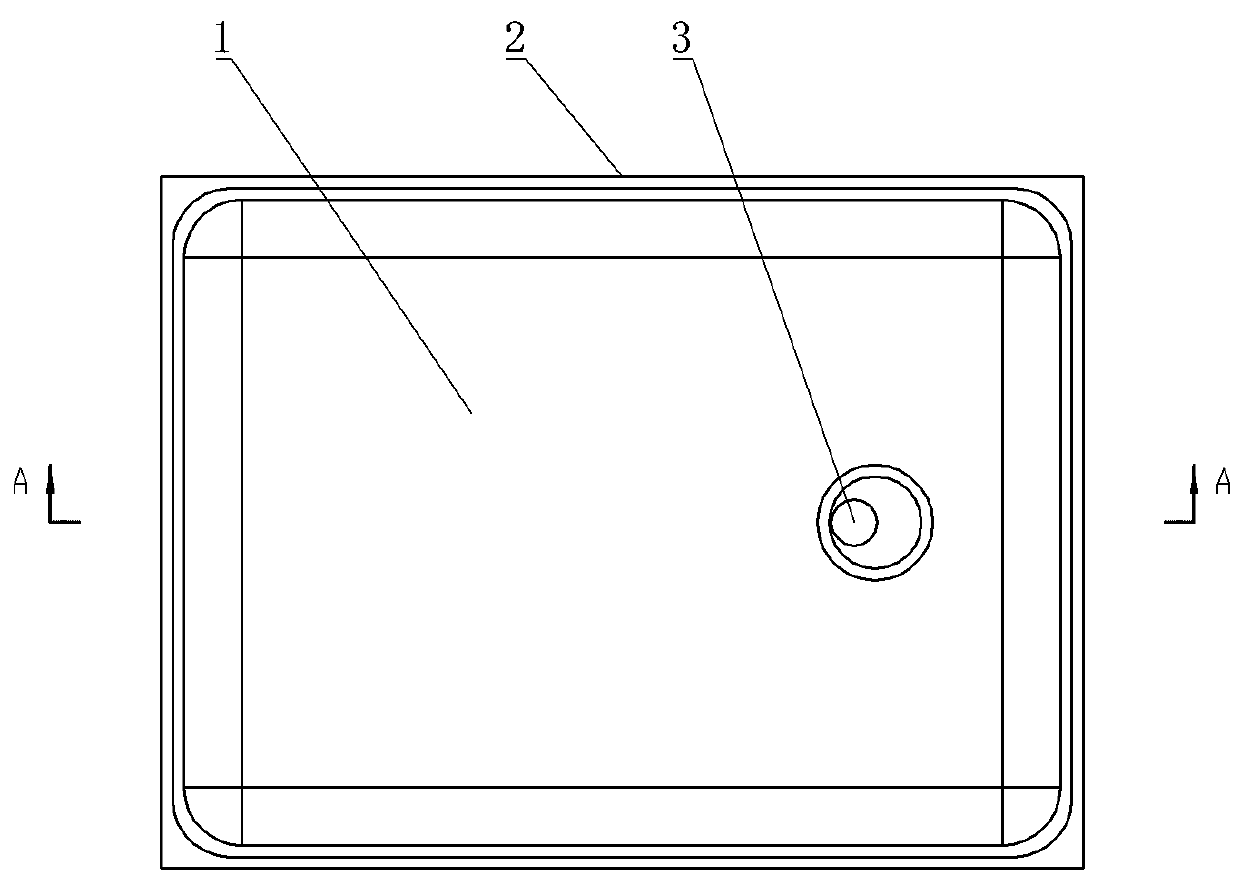

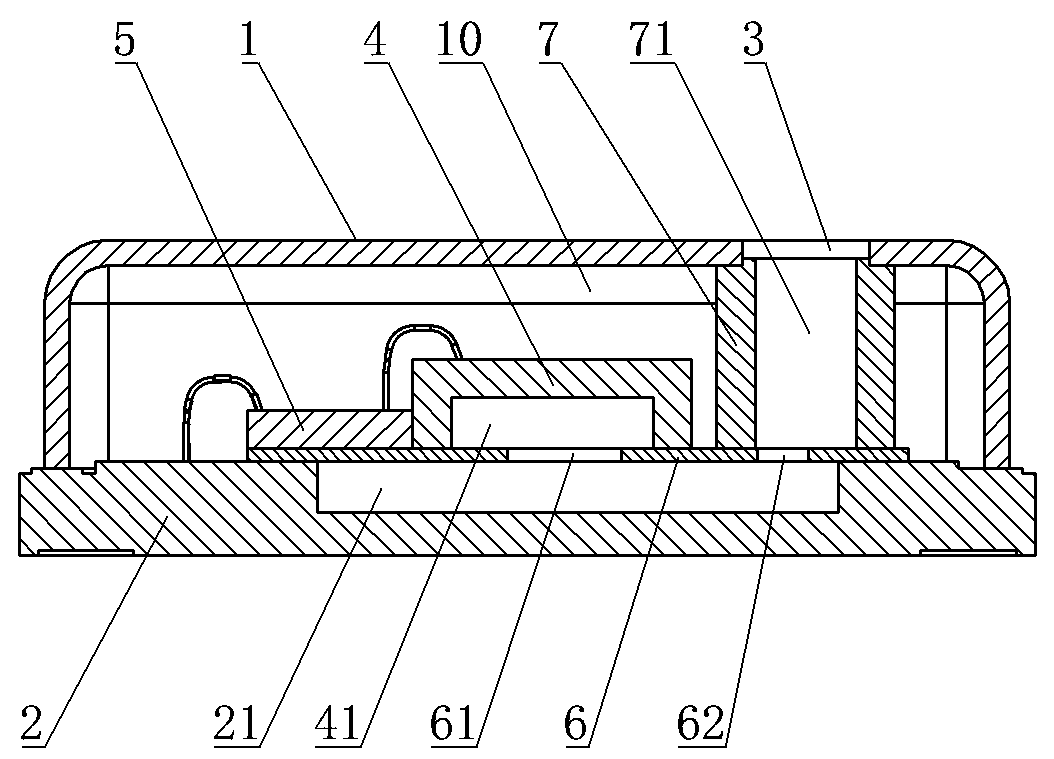

MEMS MIC with front sound cavity and rear sound cavity

PendingCN111031462AMaximize space utilizationLarge amplitudeMicrophonesLoudspeakersInterior spaceEngineering

The invention discloses an MEMS MIC with a front sound cavity and a rear sound cavity. The appearance structure is kept unchanged. An expanded rear sound cavity communicated with the rear sound cavityis formed by adding a cavity plate on a PCB. The MEMS MIC internal structure is changed. The industry common problem that the rear sound cavity of the advancing MEMS MIC is small is fundamentally solved. The utilization rate of the internal space of the MIC is maximized. The rear sound cavity volume is maximized. The problem that the volume of a traditional rear sound cavity completely depends onthe size of an MEMS sound pressure sensor chip is thoroughly solved. The current situation that the rear sound cavity volume is too small and the front and rear sound cavity volumes are not matched can be effectively improved. The size of the rear sound cavity is increased, so that the amplitude of the MEMS chip is increased. The pickup sensitivity is remarkably improved. The product sensitivityis remarkably improved under the condition that the appearance structure and the overall size are kept unchanged. The product voice is clear, natural and easy to identify, and the product tone qualityis remarkably improved.

Owner:山东新港电子科技有限公司

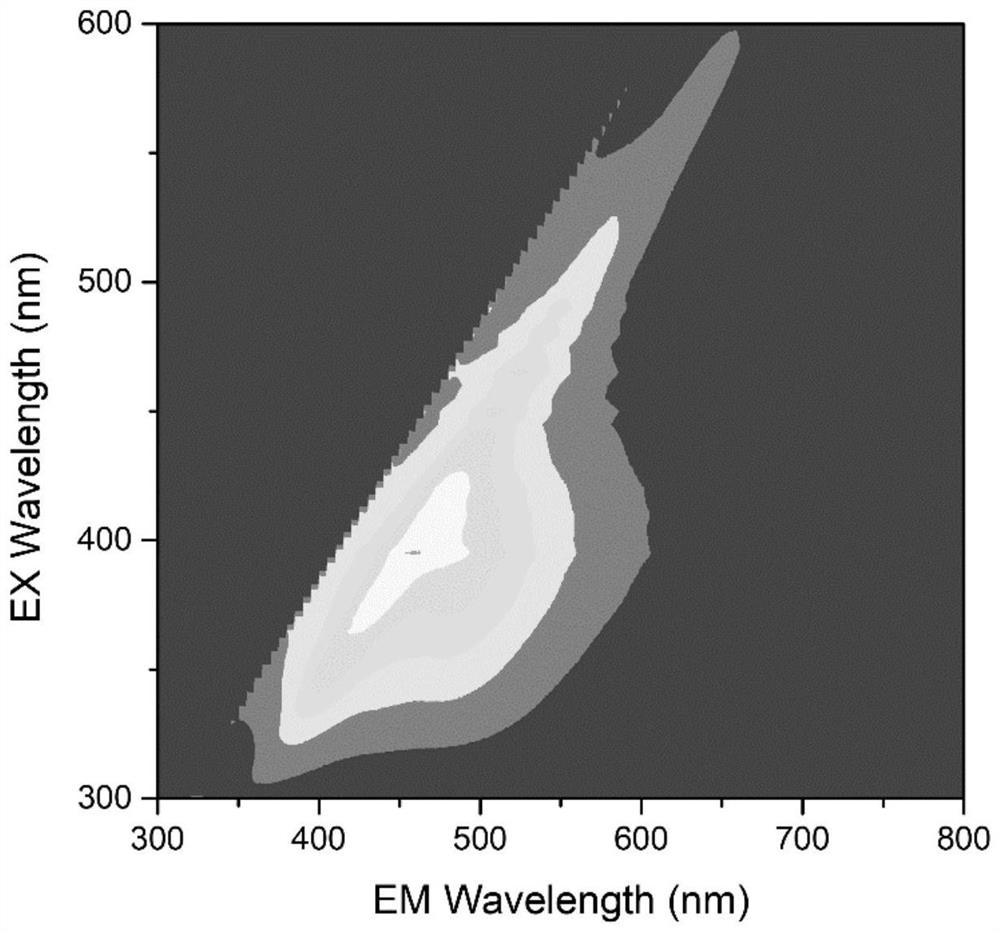

Fluorescent antibacterial polypropylene composition as well as preparation method and application thereof

ActiveCN111793272ARaw materials are easy to getMature industrial production processEscherichia coliFluorescence

The invention relates to a fluorescent antibacterial polypropylene composition as well as a preparation method and application thereof, and belongs to the field of polymer materials. The fluorescent antibacterial polypropylene composition comprises the following blended components in parts by weight: 100 parts of polypropylene resin and 0.1-20 parts of a fluorescent antibacterial polymer material;wherein the fluorescent antibacterial polymer material is a maleic anhydride copolymer zinc salt derivative. The fluorescence emission of the fluorescent antibacterial polypropylene composition underthe excitation light of 300-550 nm is located at 350-600 nm, and the strongest emission peak is 380-550 nm. The antibacterial rates of the fluorescent antibacterial polypropylene composition to escherichia coli and staphylococcus aureus are both greater than 99%. The fluorescent antibacterial polypropylene composition is low in raw material cost, simple in preparation method and low in environmental pollution. The fluorescent antibacterial polypropylene composition is excellent in fluorescence property, high in safety, lasting in antibacterial effect and suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

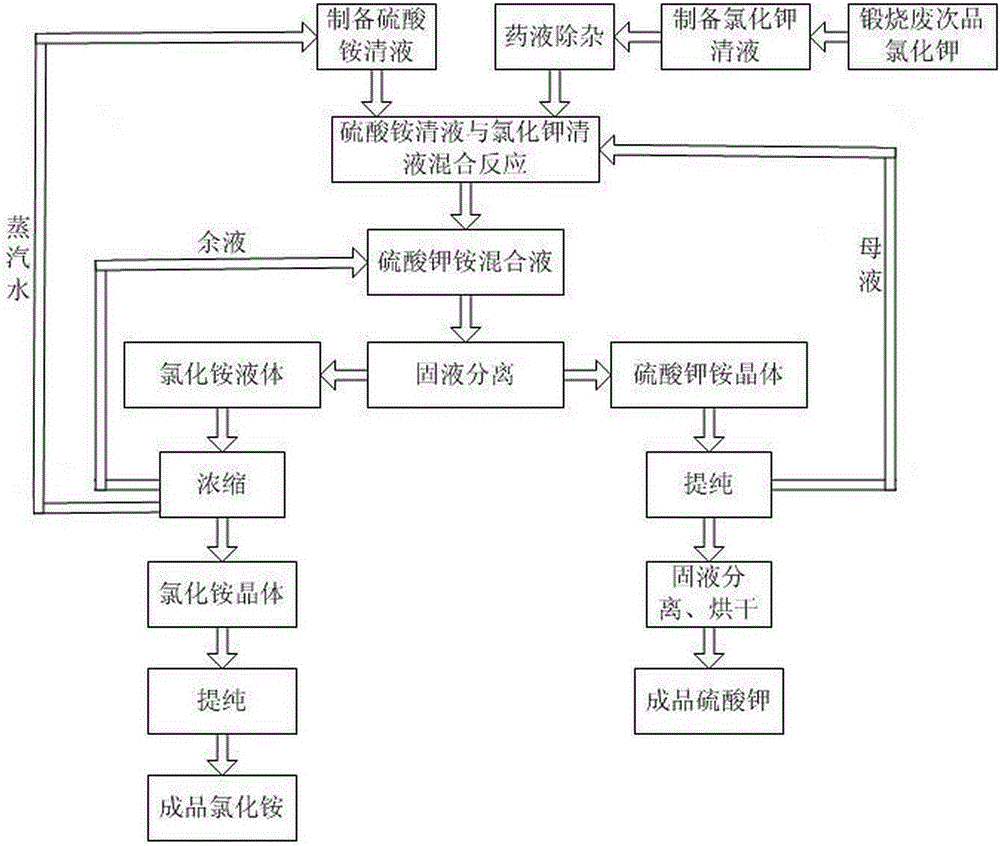

Method for producing fully-water-soluble potassium sulfate from waste/inferior potassium chloride

InactiveCN106467311AReduce pollutionEfficient removalSulfate/bisulfate preparationChemical solutionChloride

The invention discloses a method for producing fully-water-soluble potassium sulfate from waste / inferior potassium chloride. The method comprises the following steps: (a) dissolving the waste / inferior potassium chloride into water so as to obtain a potassium chloride mixed solution, filtering the potassium chloride mixed solution so as to obtain a clear potassium chloride solution, and removing impurities from the clear potassium chloride solution by using a chemical solution; (b) mixing the clear potassium chloride solution with a clear ammonium sulfate solution, so as to prepare a potassium ammonium sulfate mixed solution; (c) carrying out solid-liquid separation on the potassium ammonium sulfate mixed solution, so as to obtain potassium ammonium sulfate crystals; and (d) adding water and a catalyst into the potassium ammonium sulfate crystals, carrying out purification so as to obtain potassium sulfate, and carrying out solid-liquid separation and baking on potassium sulfate, thereby obtaining finished potassium sulfate. According to the method, the fully-water-soluble potassium sulfate can be prepared from the waste / inferior potassium chloride, and thus the aims of recycling wastes and avoiding environmental pollution are achieved.

Owner:吴有章

Production method of reagent board for detecting chloramphenicol in aquatic product

InactiveCN102288762ALow cross-reactivityStrong specificityMaterial analysisControl lineAquatic product

The invention relates to a production method of a reagent board for detecting chloramphenicol in an aquatic product, which can be used for detecting chloramphenicol residues in the aquatic product. The reagent board consists of an upper plastic template, a lower plastic template and a back lining, wherein the back lining is sequentially tightly stuck with a sample pad, a collaurum combination pad, a nitrocellulose membrane and a water sucking pad. The nitrocellulose membrane is sprayed with a detection line and a control line sequentially in the direction from the sample pad to the water sucking pad, and a reaction result can be showed with macroscopic colors. The reagent board can be used for semi-quantitative visual detection, the whole operation process only takes 20-30min, expensive laboratory equipment is not needed for assistance, and the reagent board is conductive to large-scale sample screening, is suitable for inspection and quarantine organizations, oceanic and fishery administrations, seafood quality detection departments and the like to quickly detect chloramphenicol in illegal use in aquatic products in a large scale.

Owner:杭州南开日新生物技术有限公司

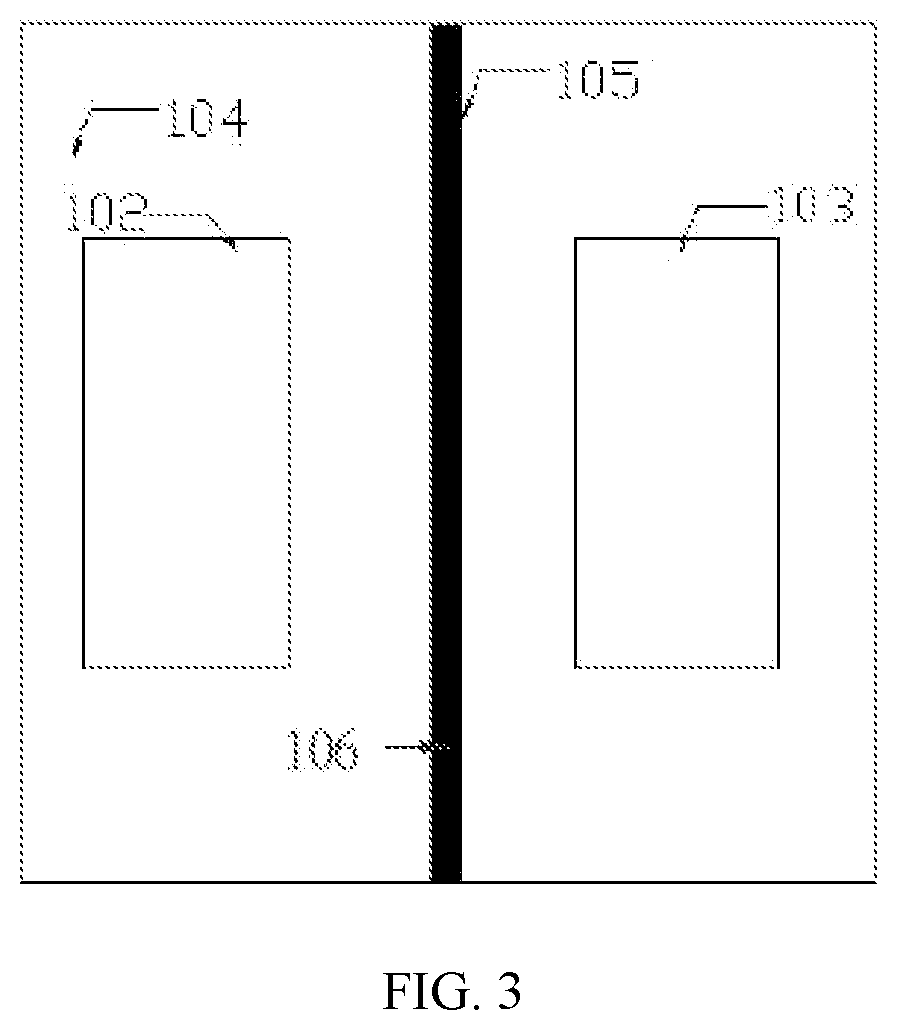

Package structure and method of manufacturing the same

ActiveUS20220020699A1Facilitate miniaturizationHigh accuracySemiconductor/solid-state device detailsSolid-state devicesRadio frequencyComposite material

The invention provides a package structure, comprising: a substrate disposed with a solid grounded copper layer; at least two radio frequency chip modules disposed on the substrate; a plastic encapsulation disposed on the substrate, covered on a surface of the substrate, and coating the at least two radio frequency chip modules therein; a groove located between the adjacent two radio frequency chip modules, and penetrating an upper surface and a lower surface of the plastic encapsulation; a solder filling body filled in the groove, wherein an upper surface of the solder filling body is flushed with the upper surface of the plastic encapsulation; and a shielding layer covered on the upper surface and lateral surfaces of the plastic encapsulation, an upper surface of the solder filling body and lateral surfaces of the substrate; wherein a position of the solid grounded copper layer corresponds to a position of the groove, and makes contact with the solder filling body in the groove.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

Method for preparing cellulose with low degree of polymerization and low crystallinity using high-temperature heat treatment

The invention relates to a method for preparing cellulose with low degree of polymerization and low crystallinity using high-temperature heat treatment. According to the method, no additional solventor solution is required, the crystalline region and amorphous region structures of the cellulose are directly destroyed by heat treatment at specified temperature and time, the effect of hydrogen bonding on the solubility of the cellulose is reduced, the dissolving activity of the cellulose is increased, and the method has the advantages of low production cost, less pollution, simple process flowand the like, and is beneficial to the regeneration processing production of the cellulose.

Owner:武汉水木弘新材料有限公司

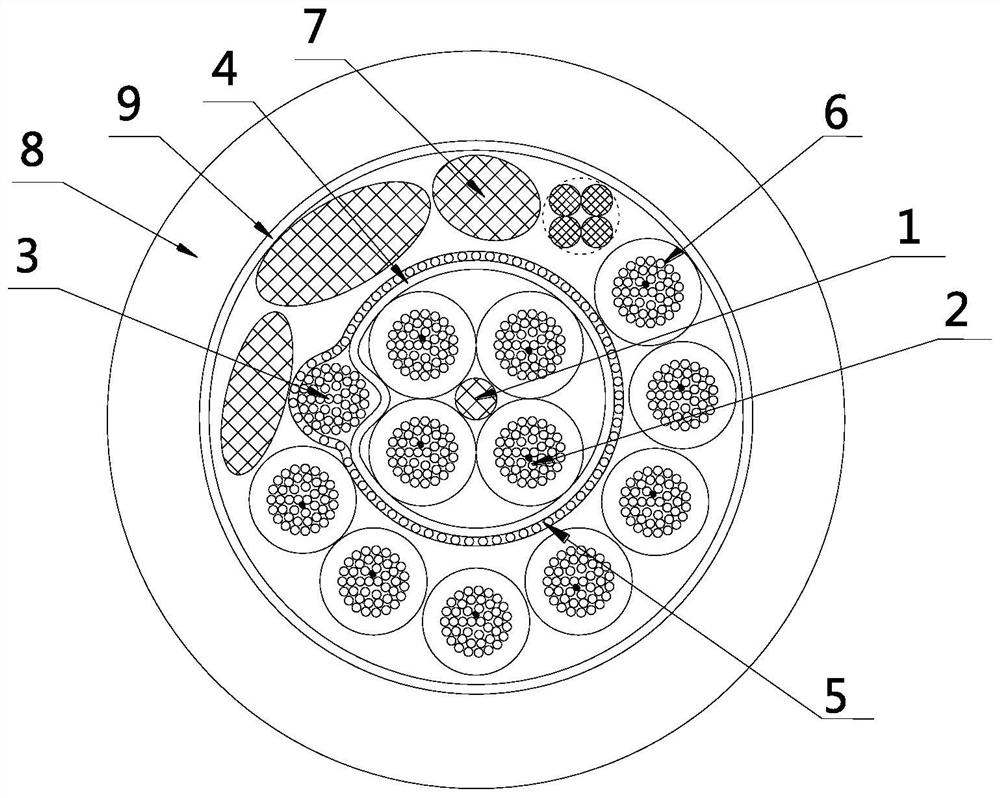

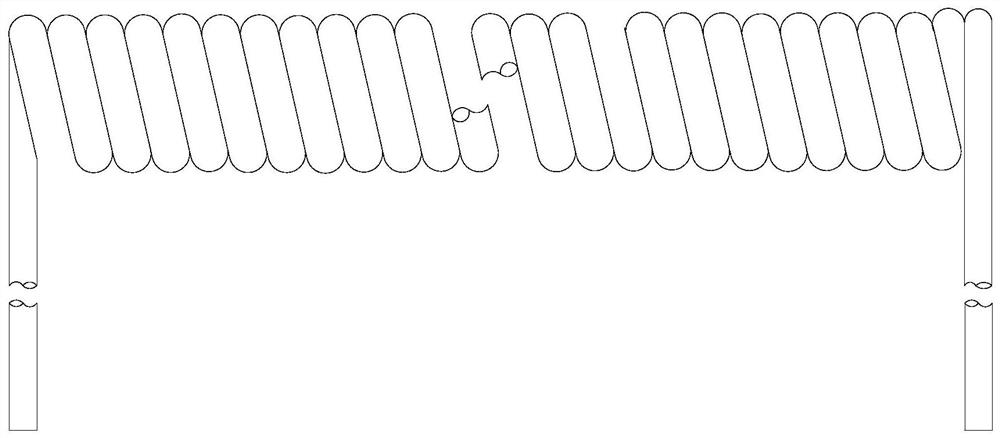

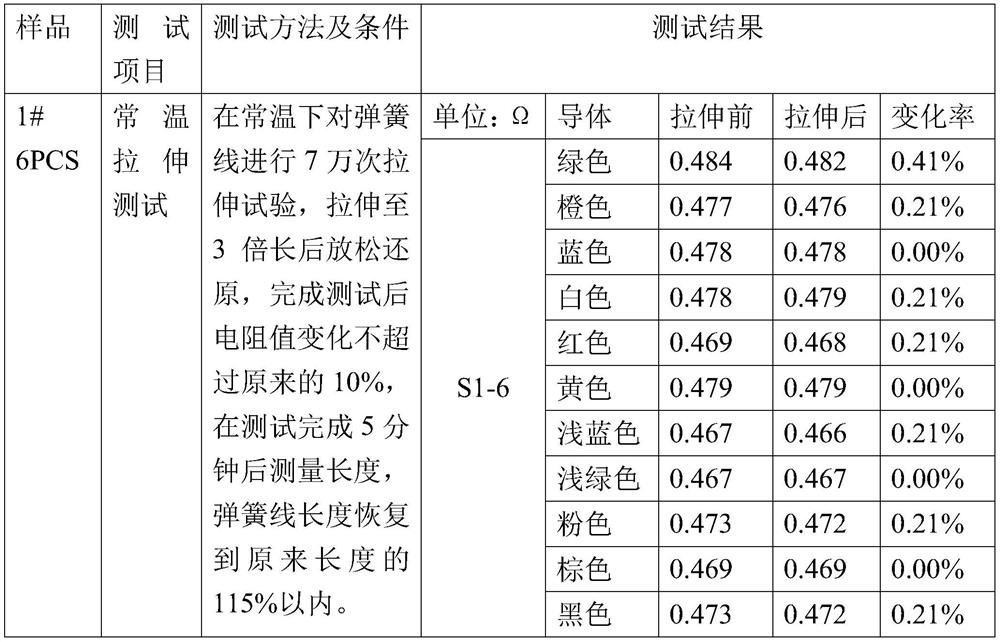

Ultrahigh-elastic torsion-resistant walkie-talkie spring wire for firefighters, and production method thereof

ActiveCN111653385AMature technologyMature processExtensible conductorsExtensible conductor cablesEngineeringFire fighter

The invention discloses an ultrahigh-elastic torsion-resistant walkie-talkie spring wire for firefighters, and a production method thereof. According to the ultrahigh-elastic torsion-resistant walkie-talkie spring wire, an inner Kevlar wire filling wire is positioned in the center; four inner core wires are arranged around the inner Kevlar wire filling wire and are twisted into a cable; the periphery of the four inner core wires is coated with a wrapping tape; the wrapping tape is coated with a shielding layer; a grounding wire is embedded between the wrapping tape and the shielding layer; andseven outer core wires and multiple outer Kevlar wire filling wires are arranged around the shielding layer and twisted into a cable, and the periphery of the outer core wires and the periphery of the outer Kevlar wire filling wires are coated with an outer sheath. According to the invention, the ultrahigh-elastic torsion-resistant walkie-talkie spring wire is used for signal transmission of a high-latitude cold zone fireman walkie-talkie communication cable or under the requirements of high and cold and flame environments, maintains the ultrahigh-elasticity torsion-resistant performance andthe continuous stability of signals, and has good torsion resistance.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

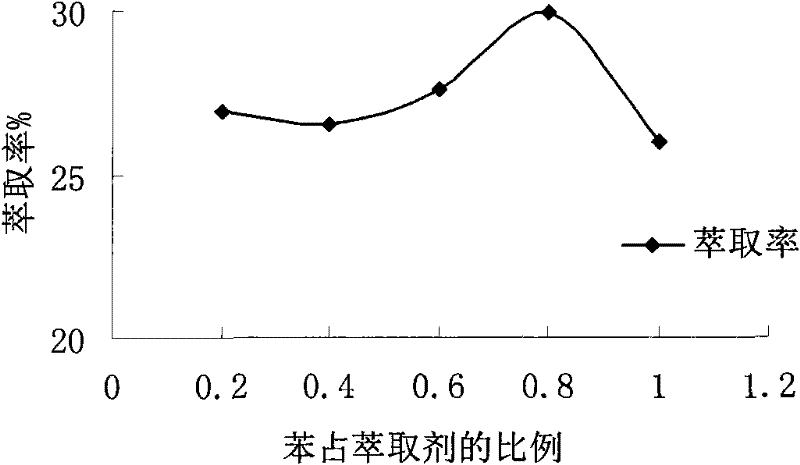

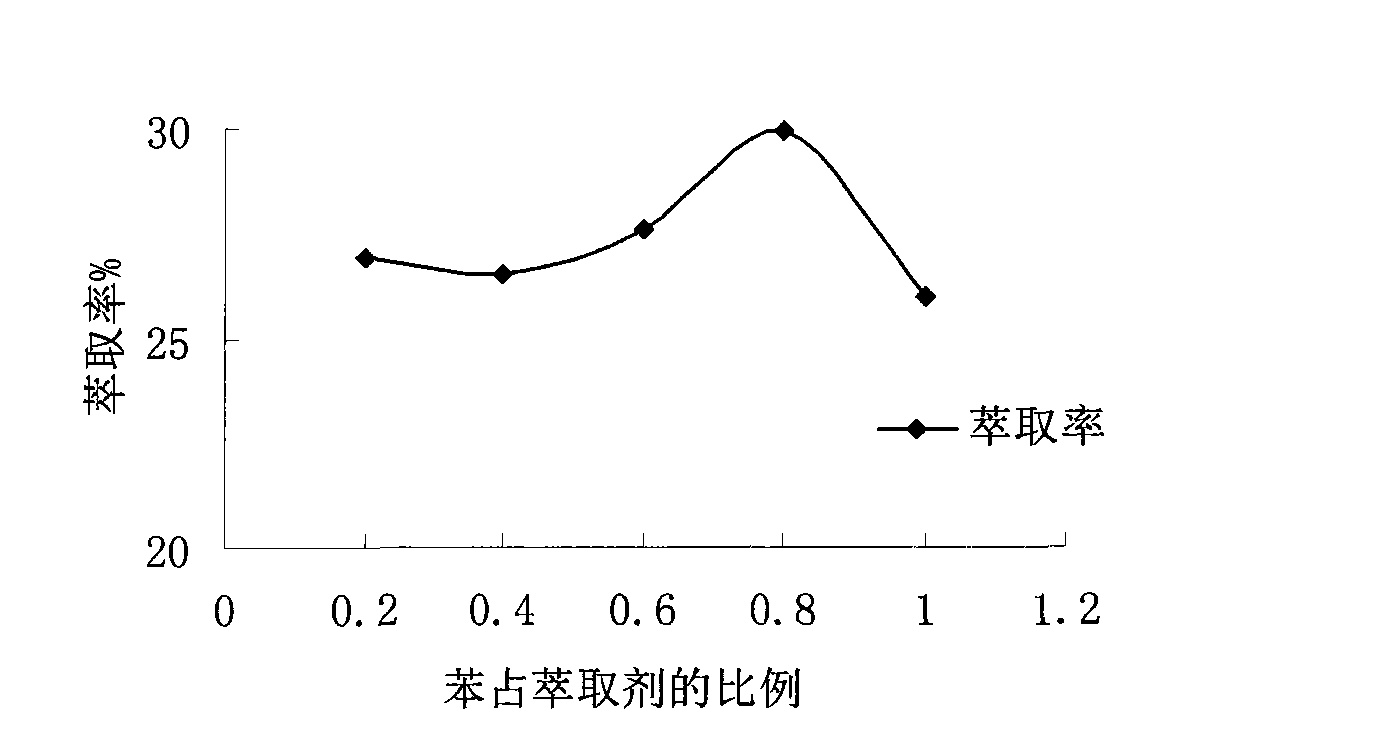

Mixed extractant for extracting methamidophos from crude oil

InactiveCN101580516BReduce lossesLow toxicityGroup 5/15 element organic compoundsLiquid solutions solvent extractionSolventTrichloroethylene

Owner:荆州沙隆达控股有限公司

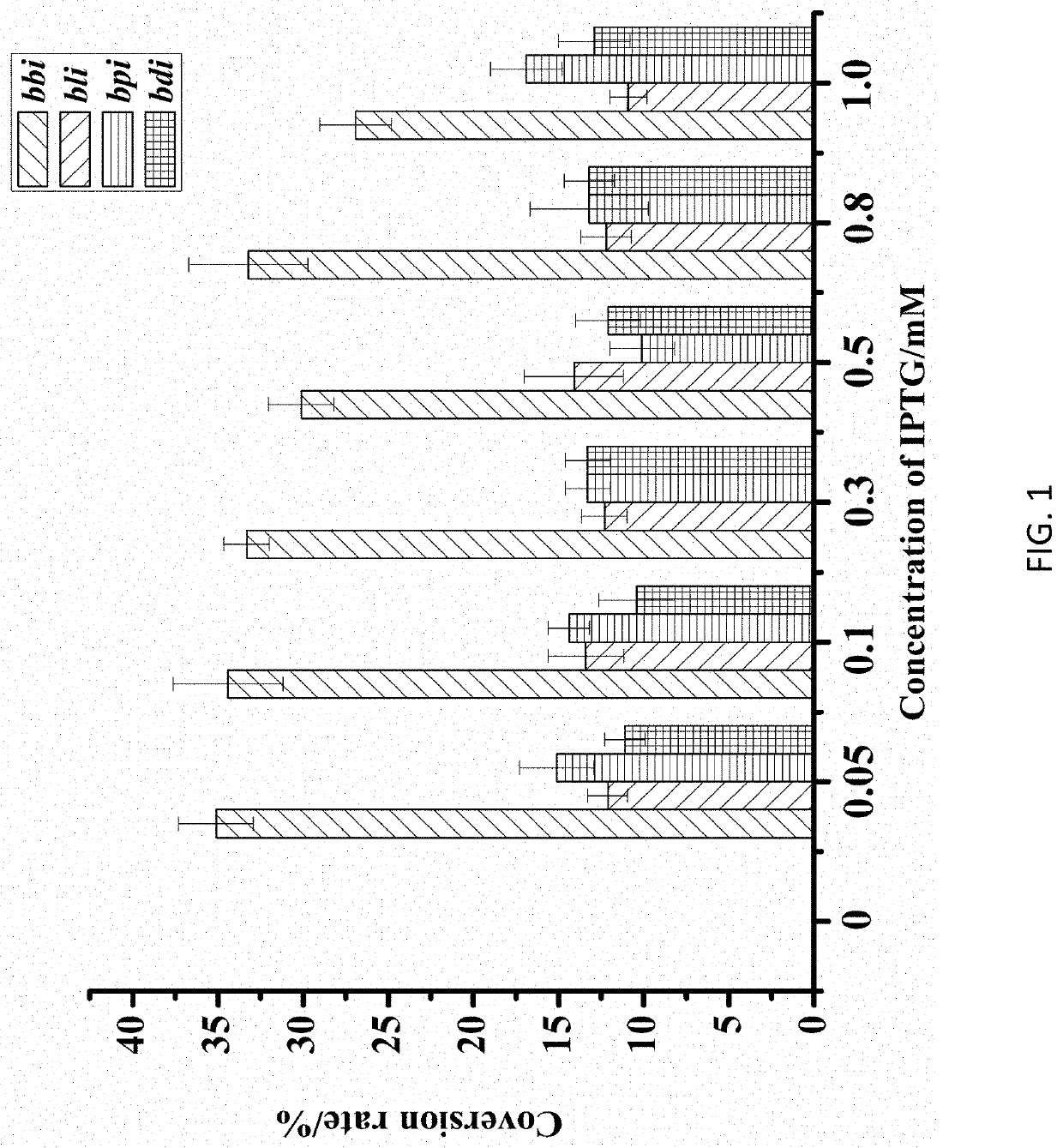

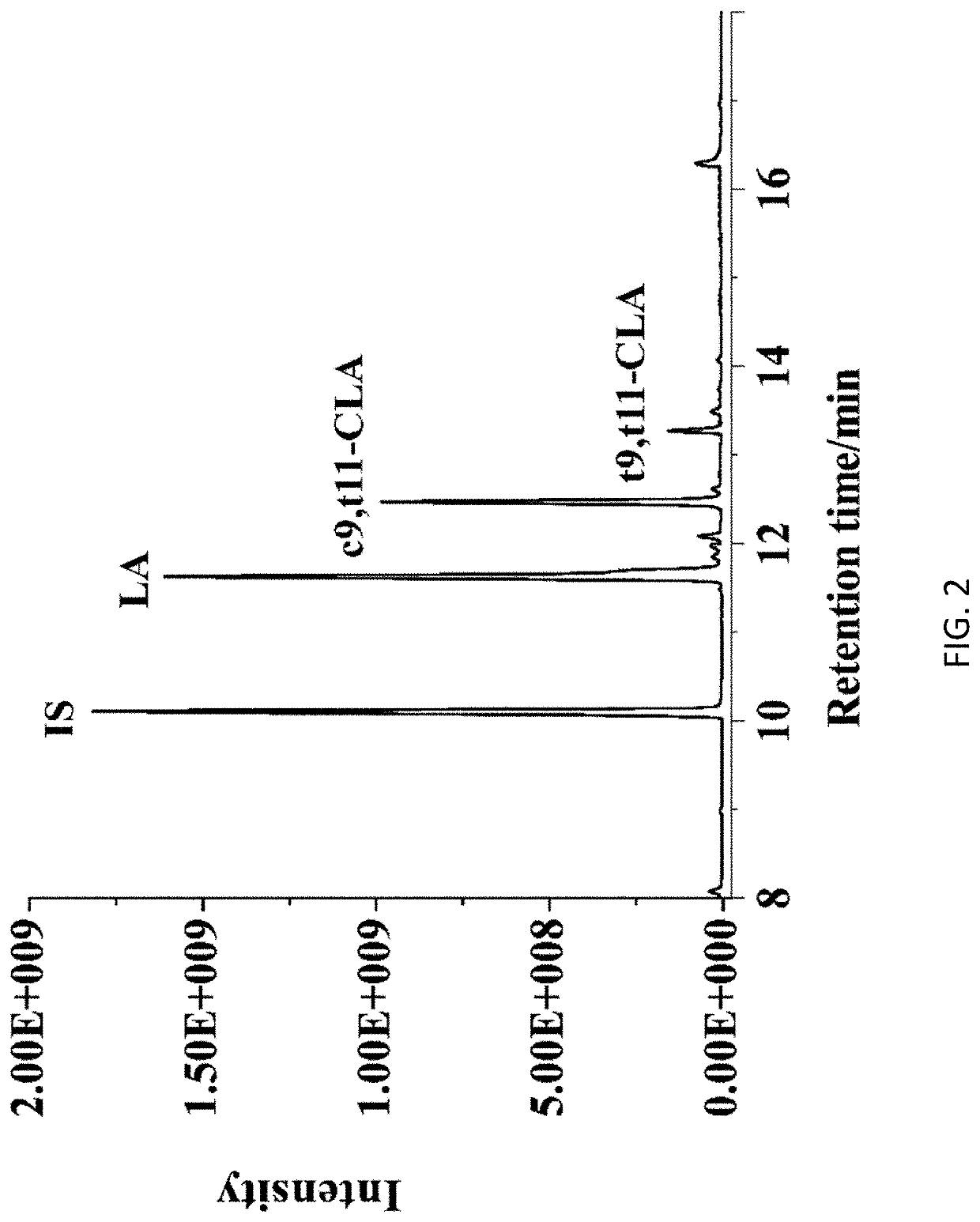

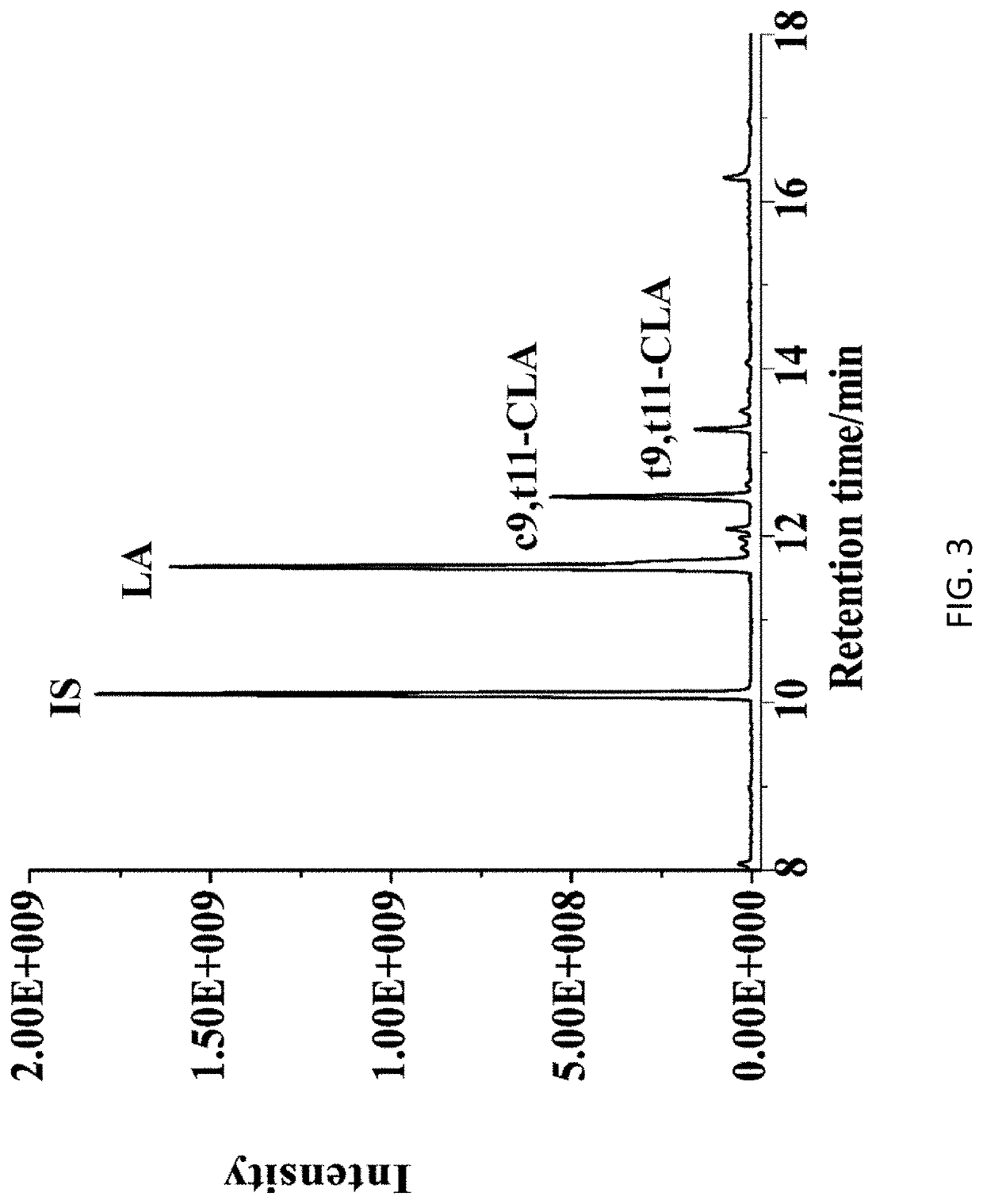

Linoleic Acid Isomerase and its Application in Production of Conjugated Linoleic Acid

PendingUS20220017886A1Mature processAbundant sourcesCis-trans-isomerasesMicroorganism based processesBifidobacteriumMicroorganism

Disclosed is linoleic acid isomerases and their application in production of conjugated linoleic acid, which belongs to the technical fields of protein engineering and microbial engineering. The linoleic acid isomerase derived from Bifidobacterium is used to produce the conjugated linoleic acid. The recombinant E. coli containing the linoleic acid isomerase of the invention is added into a reaction system containing linoleic acid and react for 3 h to produce conjugated linoleic acids. The conversion rate of the conjugated linoleic acid of the invented method ranges from 12.1% to 42.1%, and the percentage of cis9, trans11-CLA in the conjugated linoleic acid can reach 84.3% to 89.1%. The invention provides a method for using microorganisms to produce conjugated linoleic acids with high safety and yield where cis9, trans11-CLA isomer is the major form in the conjugated linoleic acid products.

Owner:JIANGNAN UNIV

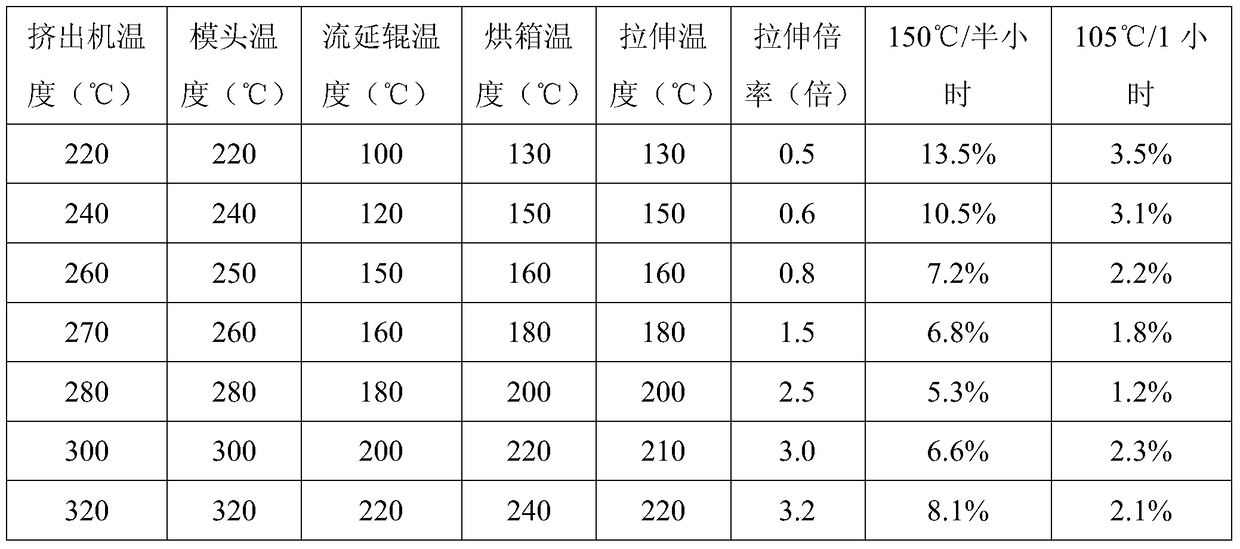

A cluster 4-methyl-1-lithium-ion battery diaphragm and its preparation method

ActiveCN105647032BEasy to processImprove aging resistanceCell component detailsPlasticizerPoly methyl pentene

The invention discloses a poly-4-methyl-1-pentene lithium-ion battery diaphragm and a preparation method thereof, which comprises poly-4-methyl-1-pentene homopolymer, poly-4-methyl-1-pentene Copolymers of structural units, antioxidants, slip agents, plasticizers and nucleating agents, etc. The invention also discloses a preparation method for processing poly-4-methyl-1-pentene lithium-ion battery diaphragm by using the raw material, comprising the following steps: Step 1: mixing poly-4-methyl-1-pentene, antioxidant, Smooth agent, plasticizer, nucleating agent and other additives are stirred evenly by a stirring mixer to obtain mixture I; step 2: adding mixture I to an extrusion casting system for casting to prepare a precursor film; step 3: Put the obtained precursor film into a constant temperature oven for annealing treatment; Step 4: longitudinally stretch the annealed precursor film to prepare a separator with a microporous structure. The diaphragm prepared by the invention has good heat resistance, low cost and simple processing procedure.

Owner:SHENZHEN SENIOR TECH MATERIAL

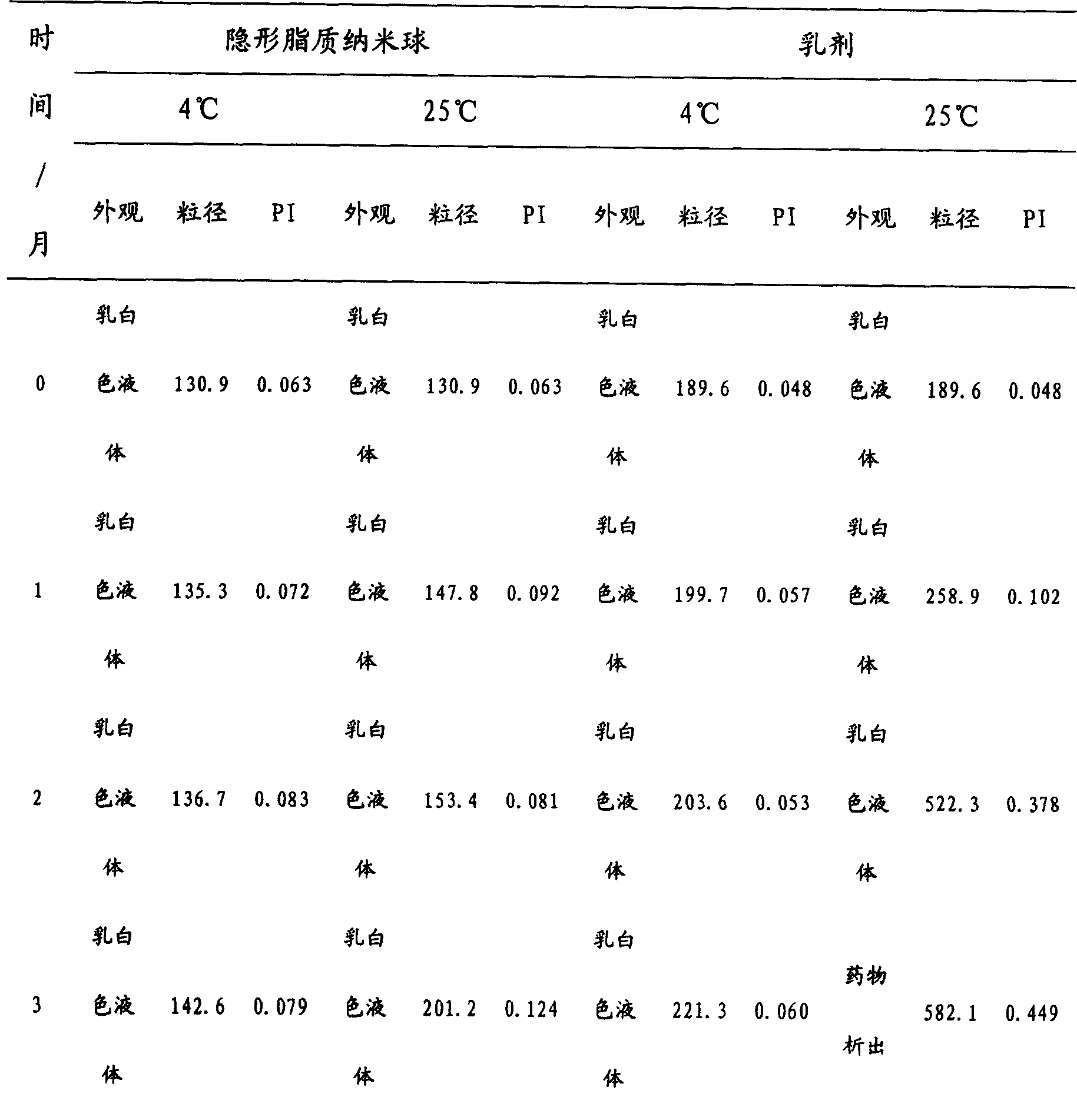

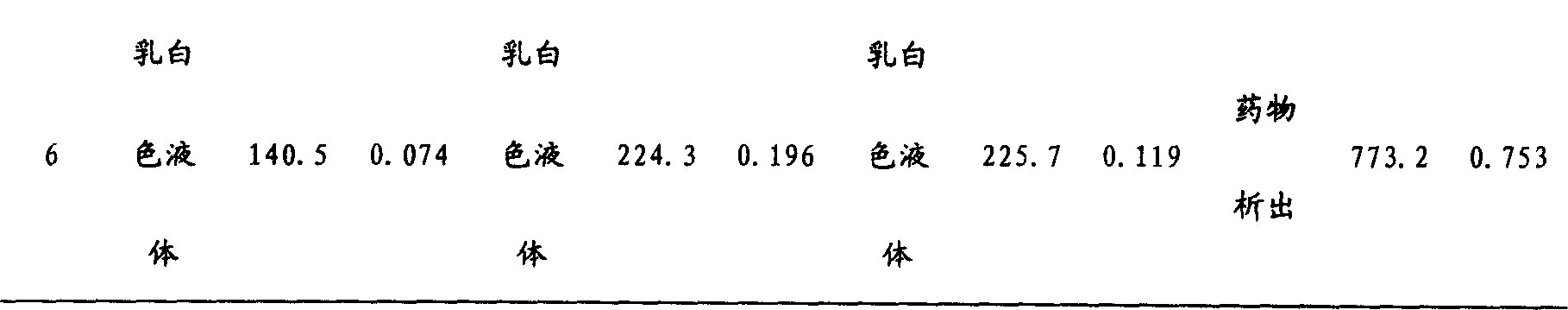

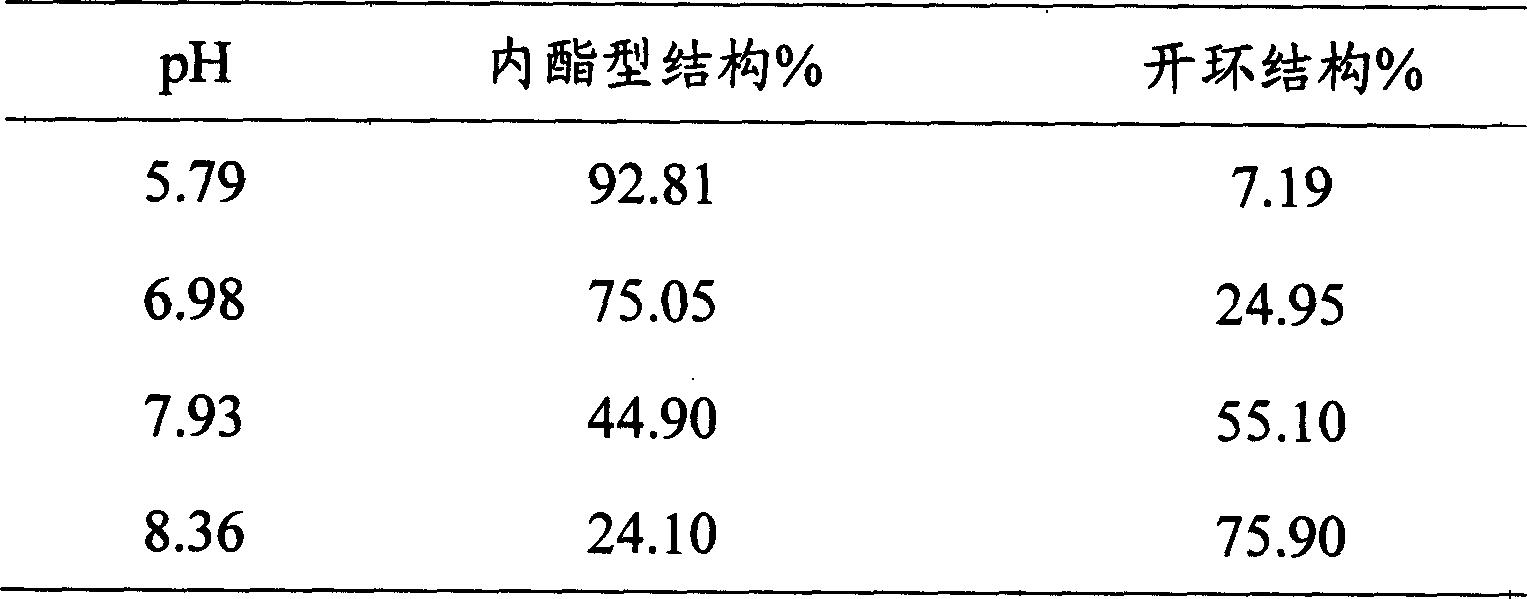

A carbowax modified stealthy liposome nanosphere of hydroxycamtothecine and preparation method thereof

ActiveCN1875944BSimple manufacturing methodMature production equipmentOrganic active ingredientsPowder deliveryOrganic solventRotary evaporator

Owner:JIANKANGYUAN PHARMA GROUP

Ore stoping method for reducing mining and cutting work amount of VCR method

PendingCN112523752ARealize continuous large-scale miningIncrease job securityUnderground miningSurface miningMining engineeringGeotechnical engineering

The invention discloses an ore stoping method for reducing mining and cutting work amount of a VCR method. The ore stoping method includes the steps that step one, a slope ramp is tunneled to the layering depth of ore body stoping; step two, the number of multi-middle-section stopes is determined according to a mine geology and ground pressure management scheme; step three, a bottom structure is constructed in the lowermost middle section, and multiple middle sections share one bottom structure for stoping; step four, a rock drilling chamber is tunneled in the upper portion of each middle section; step five, large-diameter deep hole rock drilling is conducted according to the height of each middle section; and step six, ore stoping is conducted, specifically, stoping is conducted from bottom to top by adopting a stoping mode that one stoping is conducted on every three stopes in a stope. The ore stoping method for reducing the mining and cutting work amount of the VCR method has the advantages of being safe, low in operation intensity, economical, efficient and simple and convenient in procedure.

Owner:TONGLING ZHONGDU MINING CONSTR

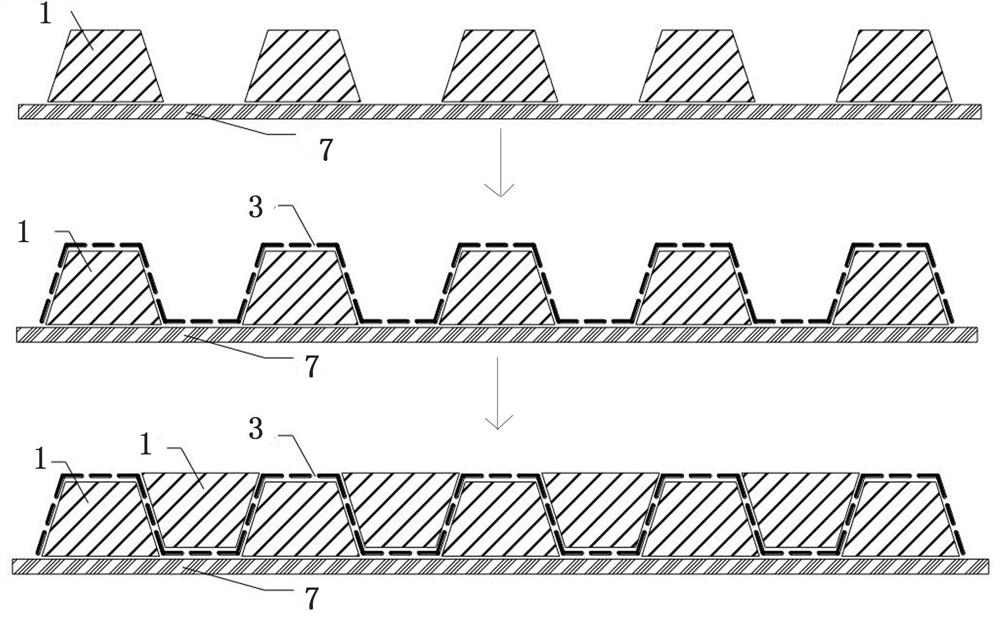

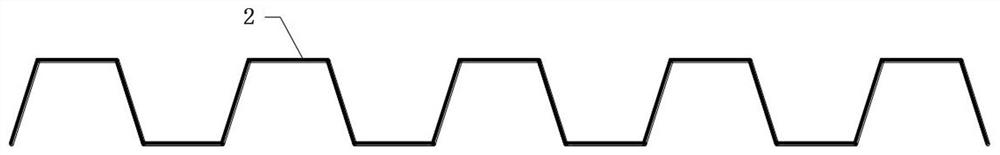

Grating structure reinforced foam sandwich composite material preparation method based on secondary forming

PendingCN114131954AEasy to operateReduce manufacturing costWeight reductionMaterials preparationGrating

The invention provides a preparation method of a grid structure reinforced foam sandwich composite material based on secondary forming, which adopts a secondary forming mode, namely, a first step of prefabricating a composite material grid structure, a second step of filling a foam core material, paving an upper panel and a lower panel, and then adopting a conventional composite material forming process for integral forming. The process amplification is easily realized, and the process risk is obviously reduced; the thickness and shape of the grating structure can be accurately controlled through a simple auxiliary tool, and the problems that in the forming process of the grating structure reinforced foam sandwich composite material, the size of an interlayer preformed body is difficult to accurately control, and the overall stability and quality consistency of a product are poor are fundamentally solved; meanwhile, through the geometric configuration design of the sub-components of the auxiliary tool and the design of the distance between the adjacent sub-components, the preparation of the reinforced foam sandwich composite materials with different types of grid structures can be realized; in addition, the auxiliary tool is easy to operate, low in manufacturing cost, large in design margin, easy to assemble and capable of being quickly assembled and disassembled, and the preparation efficiency of the preformed body is remarkably improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

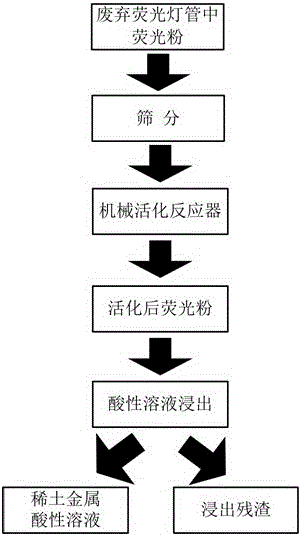

A method for enhanced leaching of rare earth metals from waste fluorescent powder by mechanical activation

ActiveCN104593608BChange physical and chemical propertiesEfficient recyclingProcess efficiency improvementActivation methodHigh energy

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

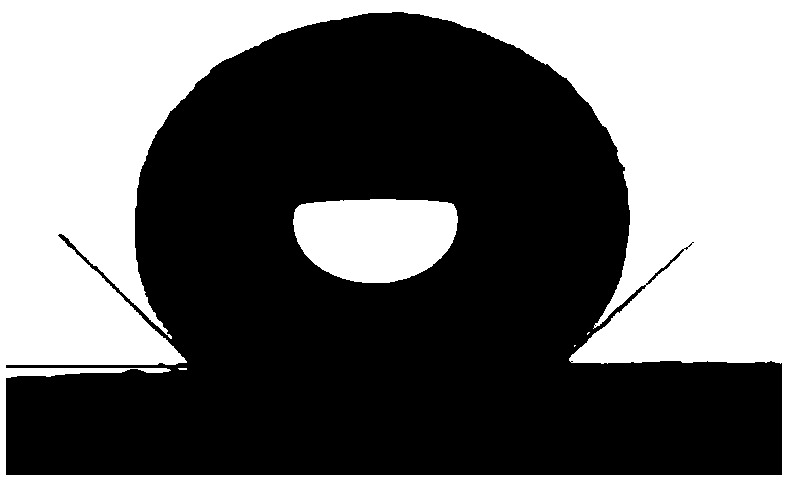

A kind of preparation method of crosslinking type highly hydrophobic nano polymer coating

ActiveCN105754439BImprove hydrophobicityImprove heat resistanceCoatingsMonomer compositionPolymer science

The invention relates to a method for preparing a cross-linked highly hydrophobic nano-polymer coating, which belongs to the field of functional polymer coatings. First, in the water system, the monomer mixture composed of monovinyl monomer and multifunctional monomer is initiated by the water-soluble initiator at 30-80°C by emulsion polymerization, and the polymer microspheres with a particle size of nanometer are prepared. ; Then convert the water in the above system into an organic solvent at room temperature, so that the nano-scale polymer microspheres are fully dispersed in the organic solvent to obtain a coating, and finally the coating is cast on the base material by casting or spin coating Form a cross-linked highly hydrophobic nano-polymer coating layer; this coating has good performance in heat resistance and solvent resistance, and does not need to contain fluorine and silicon, and is also very superior in hydrophobicity, which can reach 130 °. In addition, the film It can also remain transparent at a certain thickness. In addition, it also has the advantages of economical and easy access to raw materials, low requirements for production equipment, and no special construction conditions.

Owner:DALIAN UNIV OF TECH

Mixed extractant for extracting methamidophos from crude oil

InactiveCN101580516AReduce lossesLow toxicityGroup 5/15 element organic compoundsLiquid solutions solvent extractionSolventTrichloroethylene

The invention relates to mixed extractant for extracting methamidophos from crude oil and comprises mixed solvent consisting of solvent S and solvent K in volume ratio of 1:4-4:1; wherein, the solvent S is trichloroethylene or benzene and the solvent K is toluene, xylene or normal hexane. The solvent S and the solvent K of the invention can be miscible well, the two components can be used to make up for each other to increase the extractability, the chemical stability, the thermal stability and the phase separation property are good, the solvent loss and the toxicity are reduced, the extraction process is mature, the flow is simple, the economic benefit is obvious, the loss of the extractants is low which are not easy to emulsify, the extraction ability is strong, and the extractants are accessible and easy to recycle with a wide use range. The extracted methamidophos has high purity which can be directly used for the production and the application of methamidophos derivatives such as acephate and the like; the recovery rate of spermine is higher and the recycled spermine can be directly used to synthesize methamidophos.

Owner:荆州沙隆达控股有限公司

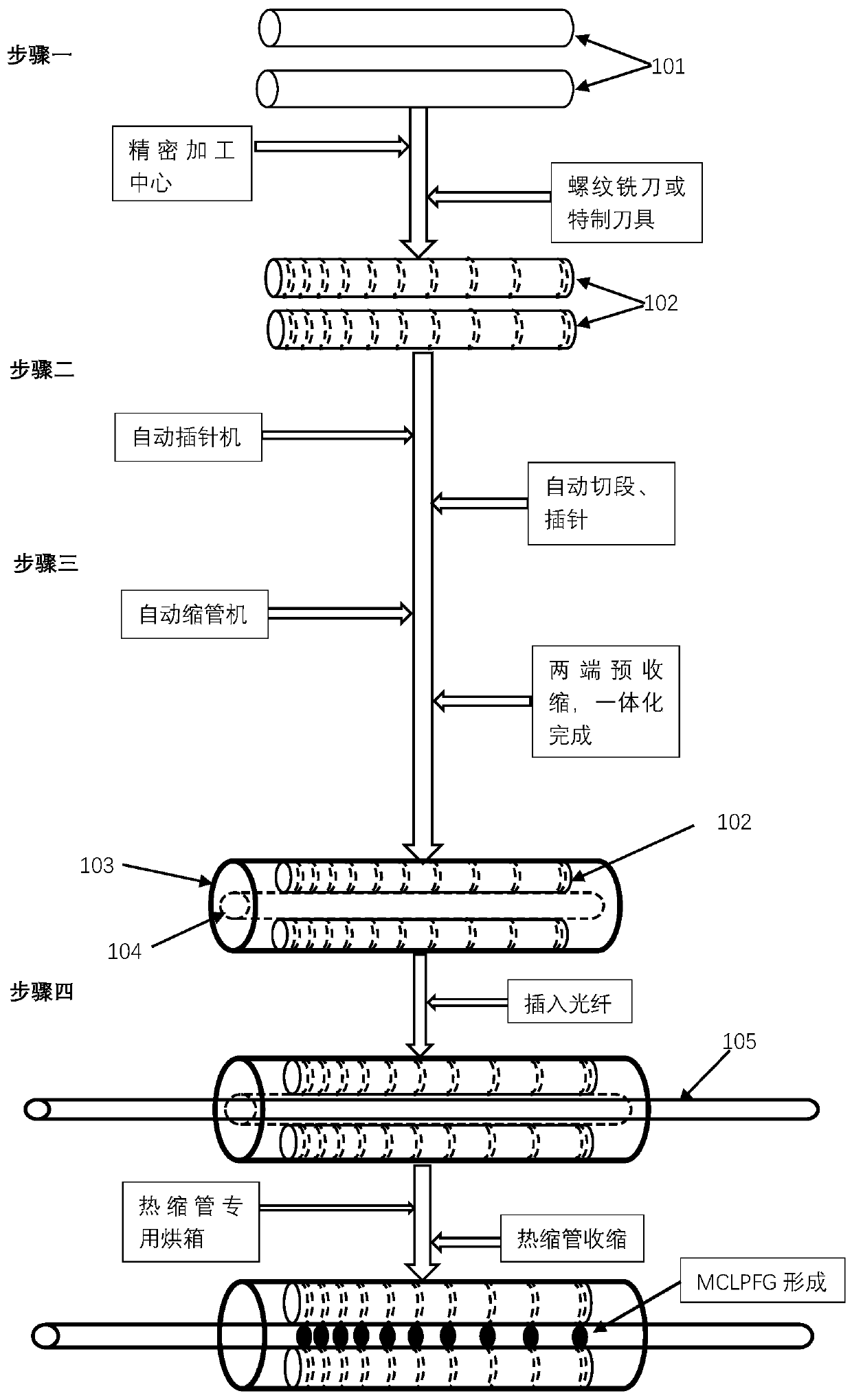

A fabrication method of mechanically chirped long-period fiber gratings

ActiveCN110320590BImprove filtering performanceImprove performanceCladded optical fibreOptical waveguide light guideFiberFiber gratings

The invention discloses a manufacturing method for a mechanical chirp long-period fiber grating. The mechanical chirp long-period fiber grating comprises a heat-shrinkage tube, a heat-melting tube, two steel needles with chirp period threads and one optical fiber, wherein the steel needles are made into chirp threaded steel needles through thread machining; the chirp threaded steel needles are placed between the heat-shrinkage tube and the heat-melting tube by using an automatic needle inserting machine and an automatic tube shrinking machine; the two ends are pre-shrunk to finish the encapsulation; then the optical fiber is placed into the heat-melting tube; the heat-melting tube is heated by using a heat-shrinkage tube drying oven, so that the chirp threaded steel needles are pressed bythe heat-shrinkage tube; and the optical fiber is pressed by the chirp threaded steel needles to produce the chirp long-period fiber grating. The manufacturing method for the mechanical chirp long-period fiber grating has the advantages of simplified process, skilled process flow, low cost and stable performance.

Owner:ZHEJIANG UNIV OF TECH

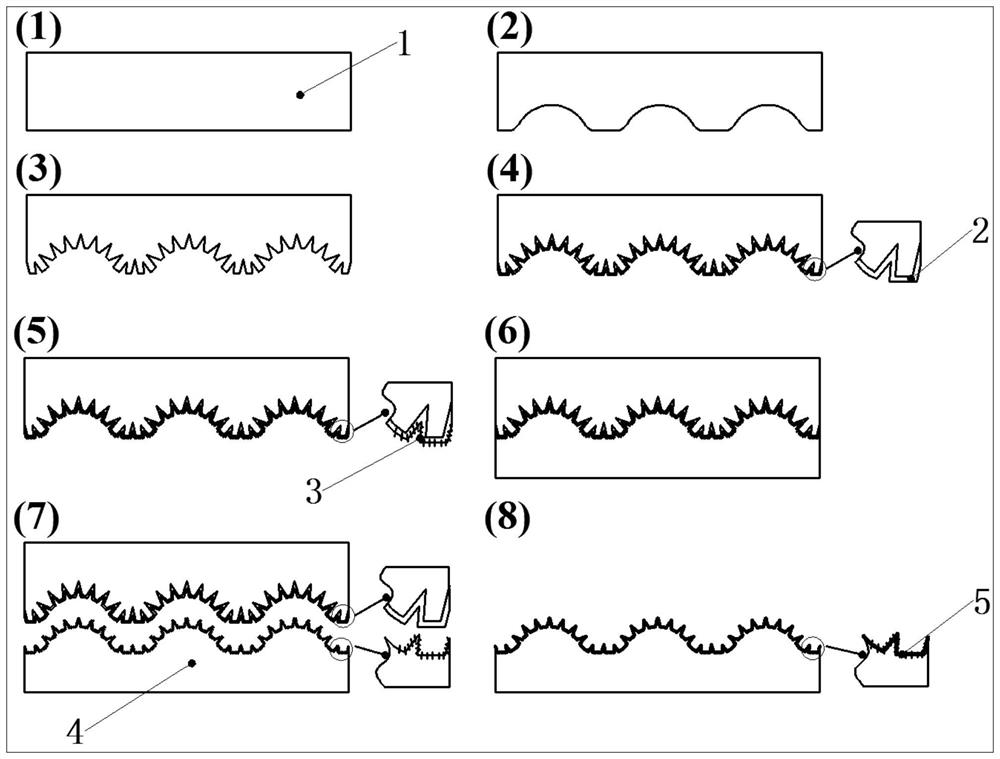

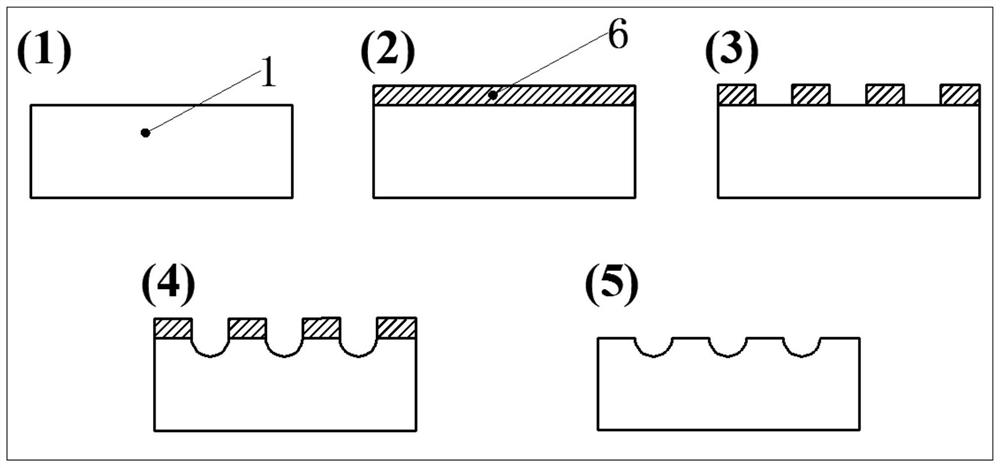

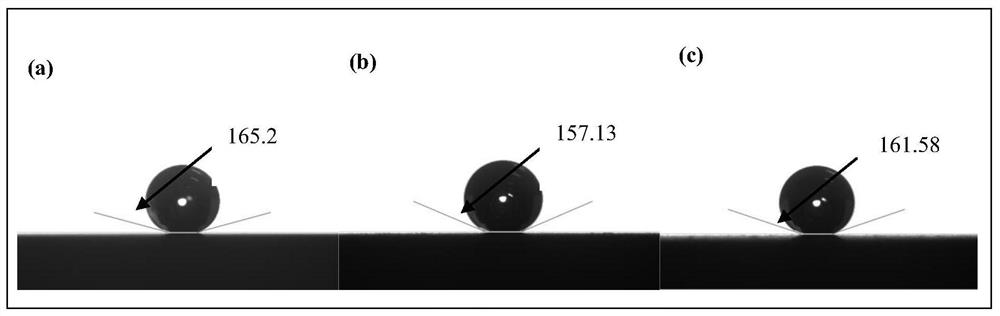

Surface design and preparation method of an anti-icing composite material

ActiveCN107931061BReduce adhesionReduce contact areaAnodisationMaterial nanotechnologyMicro nanoMicro structure

The invention belongs to the technical field of chemistry, material science and surface treatment, and particularly relates to a preparation method for an anti-icing composite material. The preparation method comprises the following steps of: (1) constructing a microstructure of a micro bulge on a metal plate surface; (2) constructing a micro-nano composite structure on the microstructure throughan inorganic particle with a nano structure; (3) compounding the micro-nano composite structure to the surface of composite material substrate through a template process to obtain a preliminary composite material; (4) coating a low-surface-energy substance layer on the surface with the micro-nano composite structure of the preliminary composite material; and (5) refining the micro-nano composite structure. The composite material obtained through the method has comprehensive performances such as a more refined micro-nano structure, high surface structural strength and good surface chemical stability; and a preparation process is simple, is economical and environmentally friendly, and is beneficial for large-scale production and application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com