Surface design and preparation method of an anti-icing composite material

A composite material and anti-icing technology, which is applied in the fields of surface treatment, chemistry, and material science, can solve the problems of difficult industrialization, cumbersome preparation process of water-based polyurethane emulsion, and unknown effect of composite materials, and achieve high surface structural strength and benefit Large-scale production and application, the effect of good surface chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

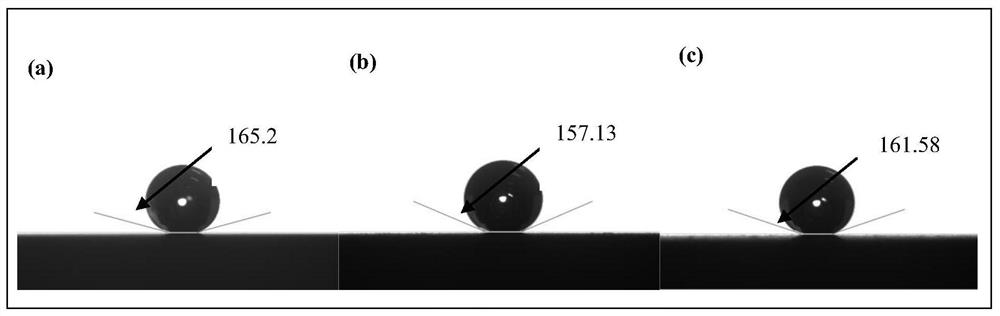

Embodiment 1

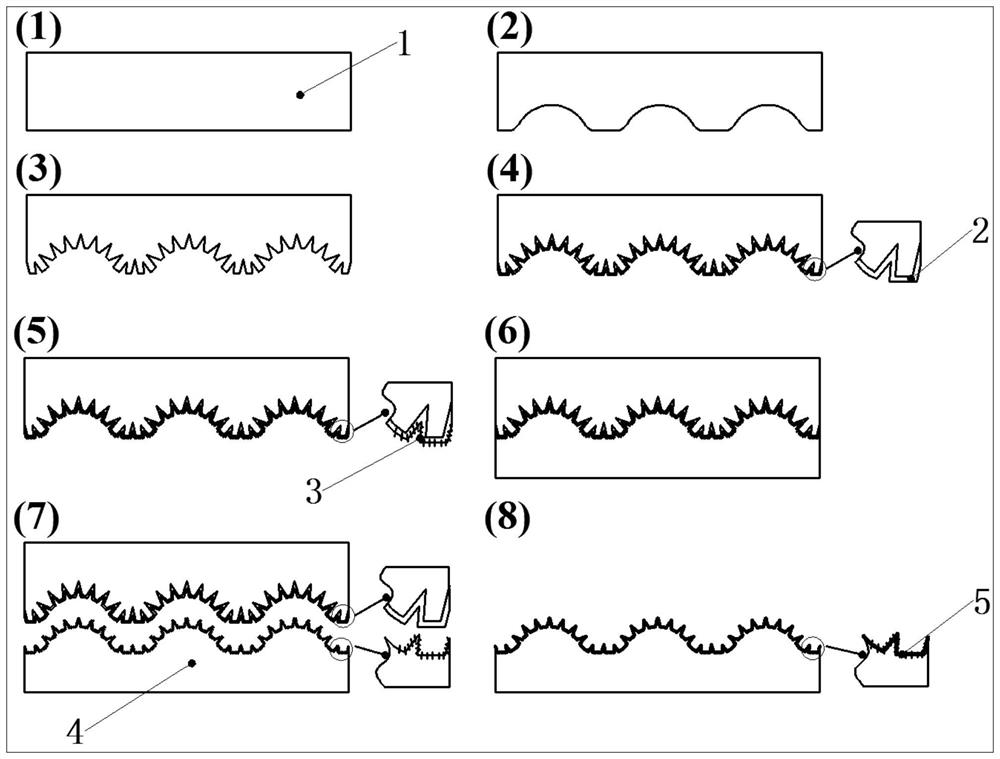

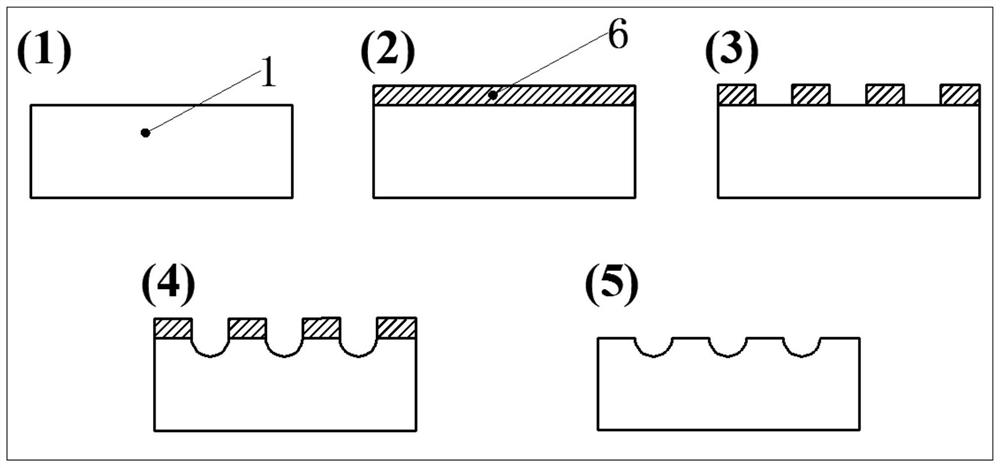

[0040] The first step is metal pretreatment. Cut a titanium plate of appropriate size, wash it with distilled water, and then put the sample into an acetone solution to clean it to remove oil; Rinse the sample with clean water and then transfer it to the acid solution for cleaning for about 40 seconds to remove the oxide film on the surface of the TA2 titanium plate.

[0041] The second step is photolithography treatment of the metal surface. 1) Put the TA2 titanium plate on the platform of the homogenizer, and spin-coat SUN-1150P positive photoresist. Set the low-speed rotation rate to 400-600rpm / min, the low-speed rotation time to 15-5s, the high-speed rotation rate to 4000rmp / min, and the high-speed rotation time to 20-30min; : 90-110℃, pre-baking time: 30-10min. 3) Exposure, exposure time: 25-40s; 4) Soak the exposed sample in SUN-238D developer solution. 5) post-baking. Post-baking temperature: 90-110°C, post-baking time: 30-10min. 6) Preparation of pickling solutio...

Embodiment 2

[0049] The first step is metal pretreatment. Cut an aluminum plate of appropriate size, wipe the surface of the aluminum alloy with cotton dipped in acetone / alcohol to remove oil stains, weigh 90g NaOH, 90g NaOH 2 CO 3 , prepare 3L alkali solution, put the aluminum alloy in the alkali solution, scrub for 0.5-1min, rinse with tap water for 2-5min, remove the residual alkali solution, when the surface of the plate is uniform white-gray, then prepare 300-500g / L Dilute nitric acid solution pickling aluminum alloy plate.

[0050] The second step is photolithography treatment of the metal surface. 1) Put the aluminum alloy plate on the platform of the glue spreader, and spin coat the negative photoresist. Set the low-speed rotation rate to 400-600rpm / min, the low-speed rotation time to 15-5s, the high-speed rotation rate to 2000rmp / min, and the high-speed rotation time to 20-30min; : 90-110℃, pre-baking time: 30-10min. 3) Exposure, exposure time: 25-40s; 4) Soak the exposed sam...

Embodiment 3

[0058] The first step is metal pretreatment. Cut a titanium plate of appropriate size, wash it with distilled water, and then put the sample into an acetone solution to clean it to remove oil; Rinse the sample with clean water and then transfer it to the acid solution for about 40 seconds to remove the oxide film on the surface of the TC4 titanium plate.

[0059] The second step is photolithography treatment of the metal surface. 1) Put the TC4 titanium plate on the platform of the homogenizer, and spin-coat SUN-1150P positive photoresist. Set the low-speed rotation rate to 400-600rpm / min, the low-speed rotation time to 15-5s, the high-speed rotation rate to 4000rmp / min, and the high-speed rotation time to 20-30min; : 90-110℃, pre-baking time: 30-10min. 3) Exposure, exposure time: 25-40s; 4) Soak the exposed sample in SUN-238D developer solution. 5) post-baking. Post-baking temperature: 90-110°C, post-baking time: 30-10min. 6) Preparation of pickling solution for corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com