A fabrication method of mechanically chirped long-period fiber gratings

A technology of fiber grating and manufacturing method, which is applied in clad optical fiber, optical waveguide, optical, etc., can solve problems such as production difficulties, and achieve the effects of low cost, mature process flow, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

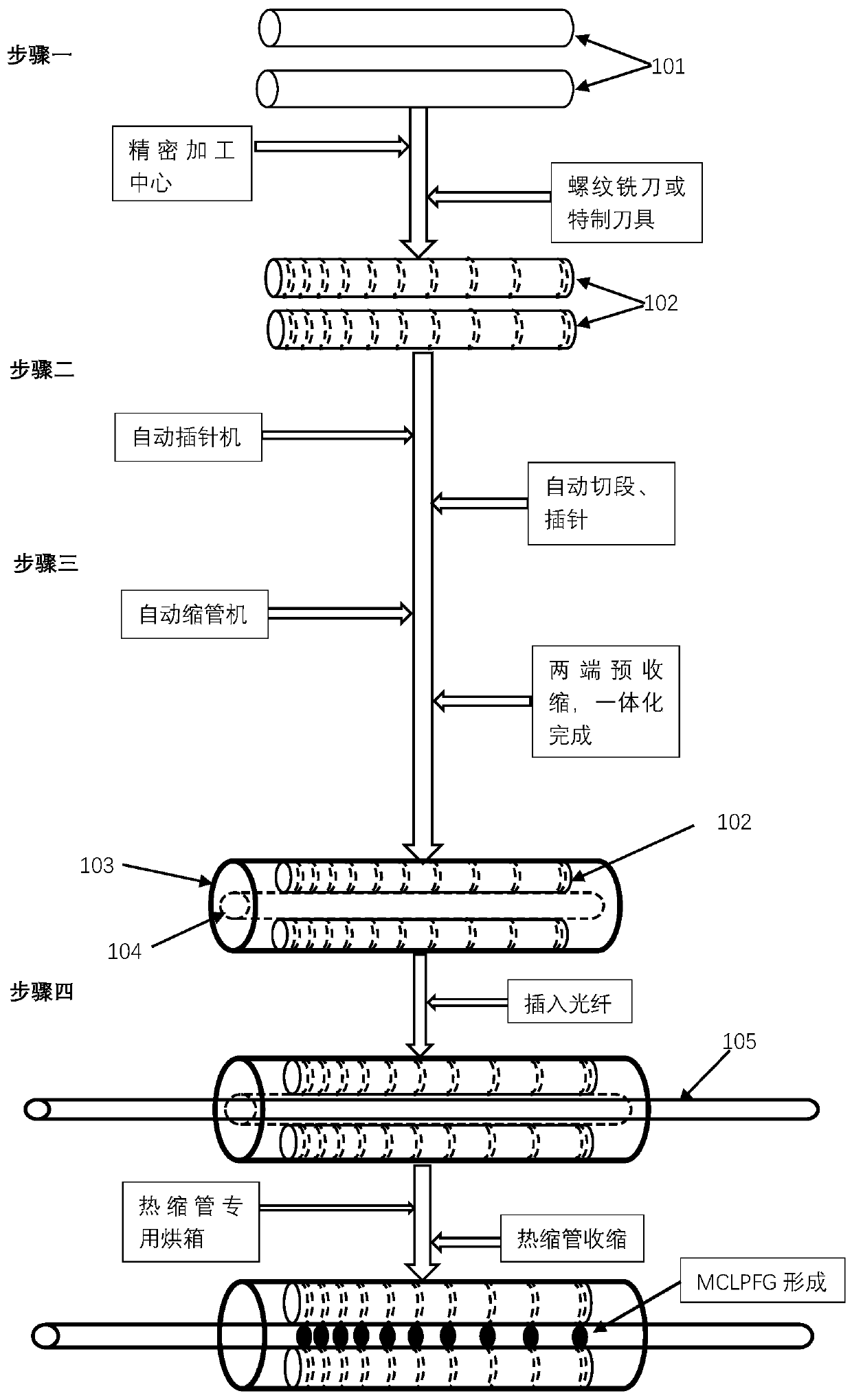

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] refer to figure 1 and figure 2 , a manufacturing method of a mechanically chirped long-period fiber grating (MCLPFG), wherein the mechanically chirped long-period fiber grating (MCLPFG) comprises a heat-shrinkable tube 103, a heat-melt tube 104, two chirped-period screw threads Steel needle 102 and an optical fiber 105, the production equipment mainly involves precision machining center, automatic needle insertion machine, automatic tube shrinking machine and heat shrinkable tube oven, the steel needle 101 is processed by thread processing to produce chirp threaded steel needle 102, Chirped rebar needle structure such as figure 2 106 is shown. Put the chirped threaded steel needle between the heat-shrinkable tube 103 and the hot-melt tube 104 by using an automatic pin insertion machine and an automatic tube shrinker, and pre-shrink both ends to complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com