A kind of preparation method of crosslinking type highly hydrophobic nano polymer coating

A nano-polymer, cross-linked technology, applied in coatings and other directions, can solve the problems of lack of thermal stability and solvent resistance, complex processing technology, etc., achieve excellent storage, mature process, improve heat resistance and The effect of solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

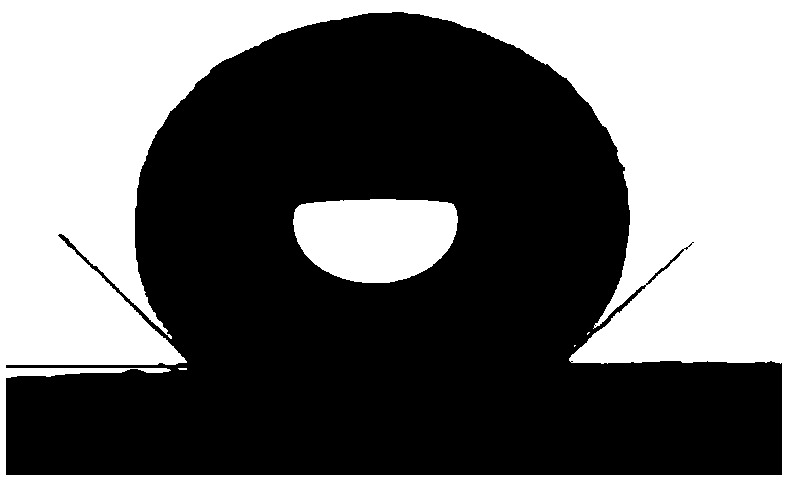

Image

Examples

Embodiment 1

[0018] After mixing butyl acrylate, styrene and N,N-methylenebisacrylamide in a mass ratio of 4:4:2, they were added to water together with 1% of the total mass of surfactant, and the monomer concentration was the total 20% of the mass, fully dispersed evenly to play the role of pre-emulsification. Ammonium persulfate was added at 70°C, and the reaction was stirred for 8 hours. After the reaction, cool to room temperature, centrifuge to change the medium from water to ethanol, and repeat the process 3 times, each time to ensure that the polymer microspheres are fully dissolved in the newly replaced medium under the condition of ultrasound. Spin-coating the coating onto a clean glass plate results in a highly hydrophobic coating with good thermal stability and solvent resistance.

Embodiment 2

[0020] After mixing butyl acrylate, styrene and ethylene glycol dimethacrylate in a mass ratio of 5:4:1, they are added to water together with 2% of the total mass of surfactant, and the monomer concentration is 1% of the total mass. 20%, fully dispersed evenly to play the role of pre-emulsification. Potassium sulfate was added at 40°C, and the reaction was stirred for 24 hours. After the reaction, cool down to room temperature, centrifuge to change the medium from water to chlorinated hydrocarbon, and repeat this process 3 times, each time to ensure that the polymer microspheres are fully dissolved in the newly replaced medium under the condition of ultrasound. The coating is cast onto clean paper to form a highly hydrophobic coating with good thermal stability and solvent resistance.

Embodiment 3

[0022] After mixing butyl acrylate, styrene and ethylene glycol dimethacrylate in a mass ratio of 5:4:2, they are added to water together with 1.5% of the total mass of surfactant, and the monomer concentration is 1% of the total mass. 20%, fully dispersed evenly to play the role of pre-emulsification. Potassium sulfate was added at 40°C, and the reaction was stirred for 16 hours. After the reaction, cool to room temperature, centrifuge to change the medium from water to acetone, and repeat the process 3 times, each time to ensure that the polymer microspheres are fully dissolved in the newly replaced medium under the condition of ultrasound. Coatings are applied by spin coating onto clean plastics to form highly hydrophobic coatings with good thermal stability and solvent resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com