Fluorescent antibacterial polycarbonate composite material as well as preparation method and application thereof

A polycarbonate, composite material technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low decomposition temperature and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

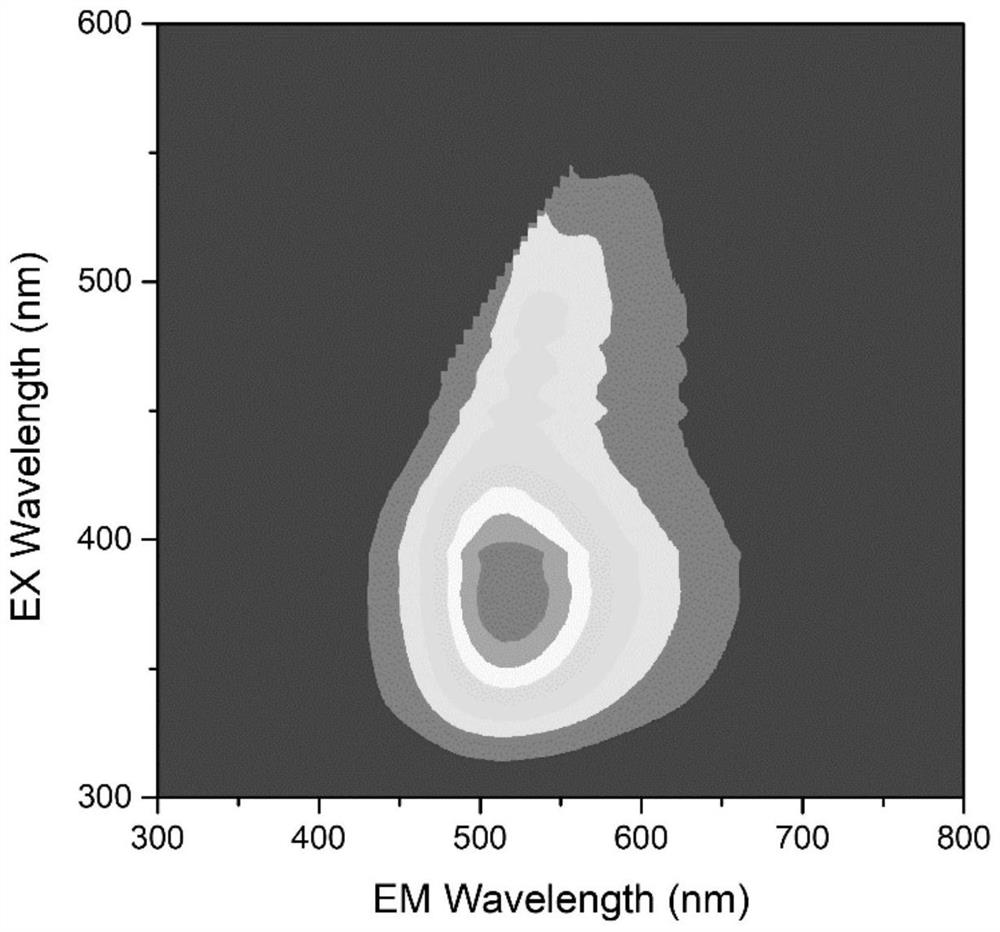

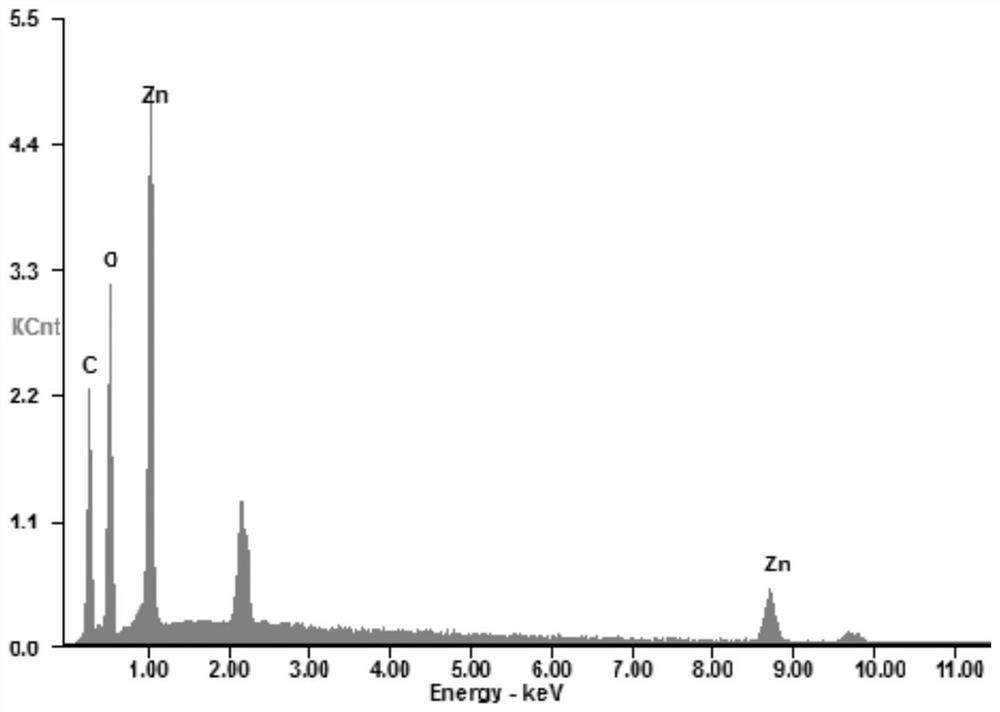

[0087] Dissolve 5g of sodium hydroxide in 100g of water; weigh 5g of MVL and put it into the aqueous solution of sodium hydroxide; after the MVL is completely dissolved, add 0.5g of zinc chloride solid, stir for 10 minutes, centrifuge the suspension and dry the precipitate to obtain Fluorescence antibacterial polymer material, its three-dimensional fluorescence spectrum is as follows figure 1 As shown, when the excitation range is 360-400 nm, the strongest emission range is 500-550 nm. The elemental energy spectrum analysis data of the fluorescent polymer material are as follows: figure 2 As shown (2.15eV is the gold element sprayed on the surface of the sample), there is zinc element in the product, and the measured weight fraction of zinc element is 20%, and no sodium element exists, indicating that the sodium element is completely replaced by zinc.

[0088] The fluorescent antibacterial polymer material was subjected to an antibacterial test according to the standard GB / T...

Embodiment 2

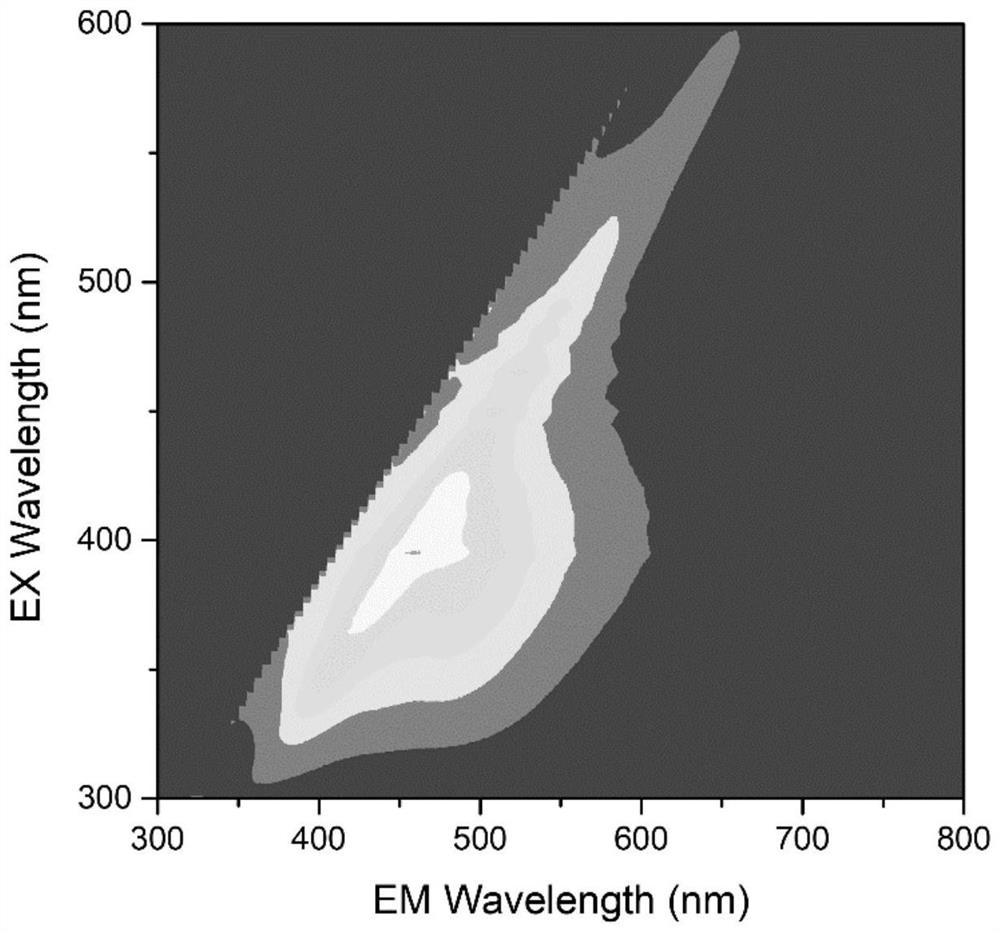

[0095] Take 0.5g of lithium hydroxide and dissolve it in 100g of water; weigh 5g of MASC and put it into the lithium hydroxide aqueous solution; after the MASC is completely dissolved, add the prepared zinc nitrate solution (50g of zinc nitrate dissolved in 50g of water), stir for 10 minutes and centrifuge The fluorescent antibacterial polymer material can be obtained by separating the suspension and drying the precipitate. Its three-dimensional fluorescence spectrum is as follows: image 3 As shown, when the excitation range is 360-425 nm, the strongest emission range is 420-490 nm. The weight fraction of the zinc element in the fluorescent antibacterial macromolecule material is 60% as measured by element energy spectrum analysis.

[0096] The fluorescent antibacterial polymer material was subjected to an antibacterial test according to the standard GB / T 21510-2008, and the antibacterial results: the antibacterial rate to Escherichia coli before boiling > 99%, and the antiba...

Embodiment 3

[0098] Take 50g of potassium hydroxide and dissolve it in 100g of water; weigh 5g of MC4L and put it into an aqueous solution of potassium hydroxide; after MC4L is completely dissolved, add zinc lactate solution (5g of zinc lactate is dissolved in 50g of water), stir for 10 minutes and then centrifuge and dry the precipitate. The fluorescent antibacterial polymer material can be obtained, and its three-dimensional fluorescence spectrum is as follows Figure 4 As shown, when the excitation range is 350-380 nm, the strongest emission range is 400-450 nm. The energy spectrum analysis of elements shows that the weight fraction of the zinc element in the fluorescent antibacterial polymer material is 47%.

[0099] The fluorescent antibacterial polymer material was subjected to an antibacterial test according to the standard GB / T 21510-2008. The antibacterial results: the antibacterial rate to Escherichia coli before boiling > 99%, and the antibacterial rate to Staphylococcus aureus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com