A cluster 4-methyl-1-lithium-ion battery diaphragm and its preparation method

A technology of lithium pentene and methyl group is applied in the field of preparation of diaphragms with simple processing procedures, which can solve problems such as poor heat resistance and achieve the effects of mature procedures, good aging resistance and overcoming adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

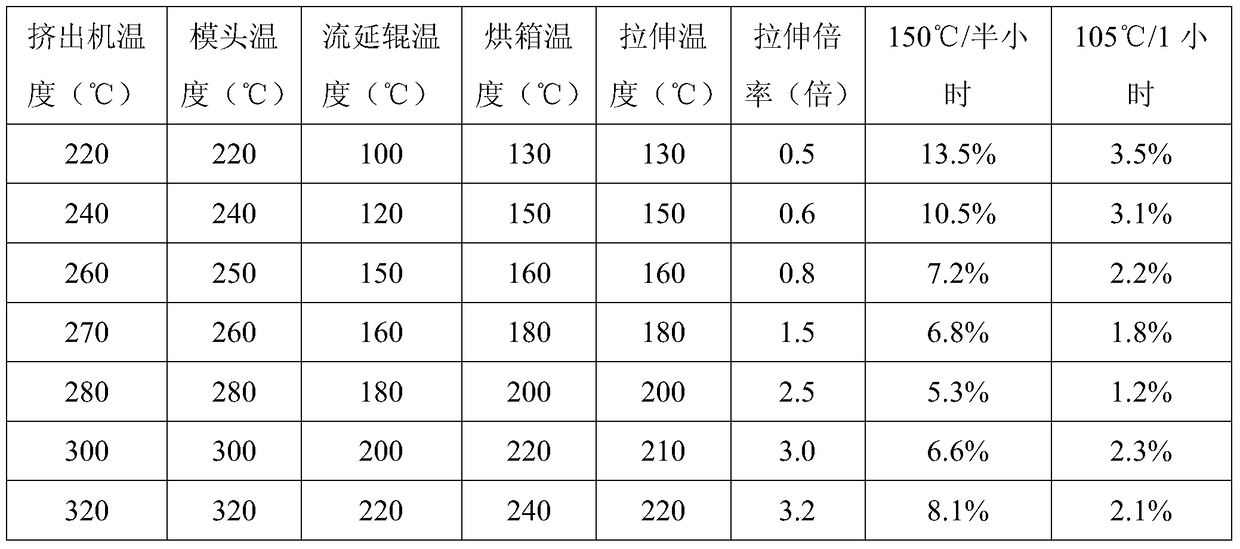

Method used

Image

Examples

Embodiment 1

[0031] Accurately weigh poly-4-methyl-1-pentene: 100kg, antioxidant 1010: 0.3kg, nucleating agent 0.5kg, slip agent 0.5 parts, plasticizer 10 parts. Precursor film A is prepared by casting in a casting system, extruder temperature: 300°C, die head temperature: 250°C, casting roll temperature: 160°C, die opening: 1.0mm, cast film thickness: 18.5um , Rewinding length: 1000m.

[0032] Put the precursor film A into a constant temperature oven for heat treatment, heat treatment temperature: 180°C, heat treatment time: 5 hours.

[0033] The heat-treated precursor film A was stretched to prepare a lithium-ion battery separator with a stretching ratio of 2.2, a stretching temperature of 190°C, and a setting temperature of 215°C.

Embodiment 2

[0035]Accurately weigh poly-4-methyl-1-pentene: 100kg, antioxidant 1010: 0.5kg, nucleating agent 5kg, slip agent 10 parts, plasticizer 10 parts. Precursor film A is prepared by casting in a casting system, extruder temperature: 300°C, die head temperature: 250°C, casting roll temperature: 160°C, die opening: 1.0mm, cast film thickness: 18.5um , Rewinding length: 1000m.

[0036] Put the precursor film A into a constant temperature oven for heat treatment, heat treatment temperature: 180°C, heat treatment time: 5 hours.

[0037] The heat-treated precursor film A was stretched to prepare a lithium-ion battery separator with a stretching ratio of 2.2, a stretching temperature of 190°C, and a setting temperature of 215°C.

Embodiment 3

[0039] Accurately weigh poly-4-methyl-1-pentene: 100kg, antioxidant 1010: 0.05kg, nucleating agent 0.05kg, slip agent 0.01 part, plasticizer 1 part. Precursor film A is prepared by casting in a casting system, extruder temperature: 300°C, die head temperature: 250°C, casting roll temperature: 160°C, die opening: 1.0mm, cast film thickness: 18.5um , Rewinding length: 1000m.

[0040] Put the precursor film A into a constant temperature oven for heat treatment, heat treatment temperature: 180°C, heat treatment time: 5 hours.

[0041] The heat-treated precursor film A was stretched to prepare a lithium-ion battery separator with a stretching ratio of 2.2, a stretching temperature of 190°C, and a setting temperature of 215°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com