Two-junction laser battery epitaxial layer and preparation method thereof

An epitaxial layer and cell technology, applied in the field of solar cells, can solve the problem of blank research on multi-junction laser cells, and achieve the effects of good cell stability, easy growth, and improved conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

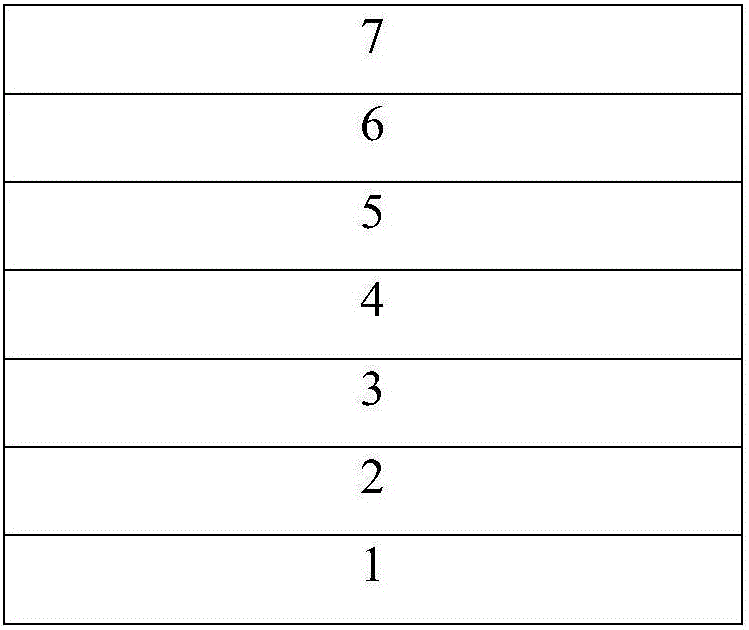

[0025] A two-junction laser solar cell, including a gallium arsenide substrate, from bottom to top, GaAs buffer layer, first tunnel junction, (AlGa) 1-x In x As graded buffer layer, GaAs battery, second tunnel junction, GaAs battery and cap layer. The production process is:

[0026] 1. Using metal organic chemical vapor deposition (MOCVD) to deposit a GaAs buffer layer on the gallium arsenide substrate;

[0027] GaAs buffer layer, the n-type dopant is Si, Se or Te, and the doping concentration is 1×10 17 -1×10 19 cm -3 , The pressure of the reaction chamber is 50-200mbar, the growth temperature is 600-700℃, and the thickness range is 100-4000nm;

[0028] 2. Growing the first tunnel junction on the GaAs buffer layer, including sequentially growing an n-type doped n+-GaInP layer and a p-type doped p+-AlGaAs layer, wherein the dopant of the n+-GaInP layer is Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com