Method for producing fully-water-soluble potassium sulfate from waste/inferior potassium chloride

A technology for potassium chloride and waste and defective products, applied in the preparation of sulfate/bisulfate, etc., can solve the problems of high energy consumption, difficult to win, complicated process, etc., to reduce pollution, reduce the discharge of waste residue, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

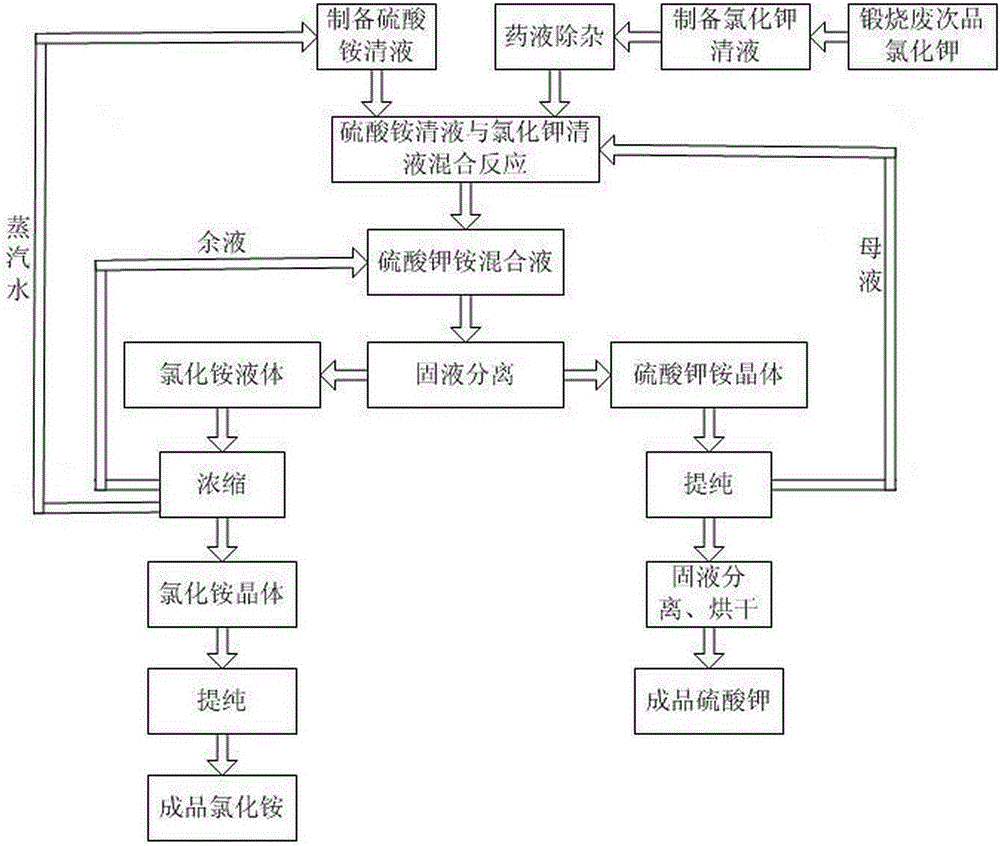

Image

Examples

Embodiment 1

[0033] A kind of method utilizing waste and inferior product Repone K to produce fully water-soluble potassium sulfate comprises the following steps:

[0034] a. First, the waste and defective potassium chloride was calcined at a temperature of 300°C for 10 minutes to remove harmful impurities and organic impurities in the waste and defective potassium chloride, and then the waste and defective potassium chloride after calcination Add it into water, stir and dissolve at a temperature of 80°C to obtain a potassium chloride mixed solution, filter the potassium chloride mixed solution to obtain a potassium chloride clear liquid, and then prepare the corresponding medicinal solution, and use the medicinal solution to eliminate Impurities in potassium chloride clear liquid; among them, the mass ratio of waste and defective potassium chloride dissolved in water is 1:1.8.

[0035] b. Stir and mix ammonium sulfate and water at a temperature of 80°C at a mass ratio of 1:0.95 to obtain ...

Embodiment 2

[0043] A kind of method utilizing waste and inferior product Repone K to produce fully water-soluble potassium sulfate comprises the following steps:

[0044] a. First, the waste and defective potassium chloride is calcined at 500°C for 7 minutes to remove harmful impurities and organic impurities in the waste and defective potassium chloride. The waste gas produced by calcination is washed with water, and the washing water is returned to In step a, the waste and inferior product potassium chloride after calcining is added to water, and stirred and dissolved at a temperature of 90° C. to obtain a potassium chloride mixed solution, and the potassium chloride mixed solution is filtered to obtain potassium chloride clear liquid, and then prepare the corresponding liquid medicine, and use the liquid medicine to eliminate impurities in the potassium chloride clear liquid; wherein, the mass ratio of the waste and defective potassium chloride dissolved in water is 1:1.9.

[0045] b. ...

Embodiment 3

[0050] A kind of method utilizing waste and inferior product Repone K to produce fully water-soluble potassium sulfate comprises the following steps:

[0051] a. First, the waste potassium chloride is calcined at 1300°C for 3 minutes to remove harmful impurities and organic impurities in the waste potassium chloride. The waste gas produced by calcination is washed with water, and the washing water is returned to In step a, the waste and inferior product potassium chloride after calcining is added to water, and stirred and dissolved at a temperature of 100° C. to obtain a potassium chloride mixed solution, and the potassium chloride mixed solution is filtered to obtain potassium chloride clear liquid, and then prepare the corresponding liquid medicine, and use the liquid medicine to eliminate impurities in the potassium chloride clear liquid; wherein, the mass ratio of the waste and defective potassium chloride dissolved in water is 1:2.

[0052] b. Stir and mix ammonium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com