High-wettability lithium-ion battery separator and preparation method thereof

A technology for lithium-ion batteries and battery diaphragms, applied in the field of highly wettable lithium-ion battery diaphragms and their preparation, can solve the problems of large diaphragm pore size, deterioration of diaphragm performance, poor mechanical properties, etc., achieve mature processes and improve electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

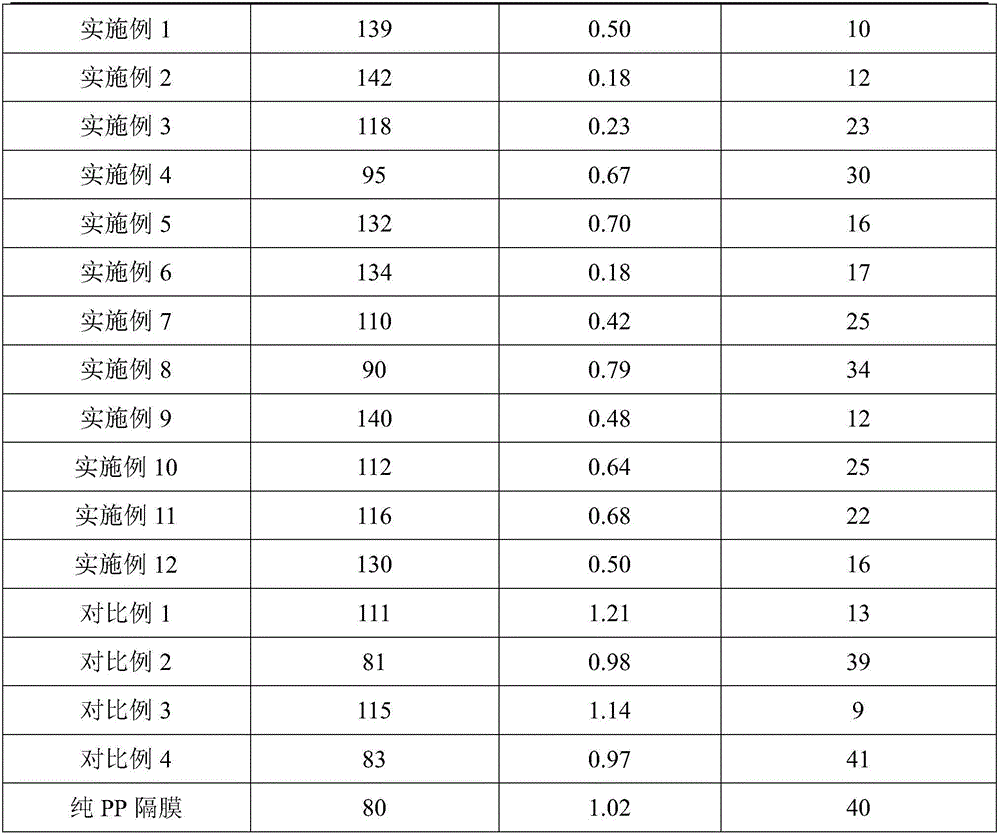

Examples

Embodiment 1

[0023] Accurately weigh the acrylic resin: 10kg, acetone: 90kg; dissolve the acrylic resin in acetone at 20°C, apply it on the surface of the polypropylene separator by dimple coating, and dry it at 60°C after 10s. (Acrylic resin molecular weight is 10000)

Embodiment 2

[0025] Accurately weigh the acrylic resin: 5kg, acetone: 95kg; dissolve the acrylic resin in acetone at 20°C, apply it on the surface of the polypropylene separator by dimple coating, and dry it at 60°C after 10s. (Acrylic resin molecular weight is 10000)

Embodiment 3

[0027] Accurately weigh the acrylic resin: 1.5kg, acetone: 98.5kg; dissolve the acrylic resin in acetone at 20°C, apply it on the surface of the polypropylene diaphragm by dimple coating, and dry it at 60°C after 10s. (Acrylic resin molecular weight is 10000)

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com