Ultrahigh-elastic torsion-resistant walkie-talkie spring wire for firefighters, and production method thereof

A production method and torsion-resistant technology, applied in the direction of cables, insulated conductors, and extendable conductor cables, etc., can solve the problems of twisting and deformation of data transmission core wires, insufficient rebound rate, fracture, etc., to eliminate rebound stress, maintain The effect of continuous and stable signal and controllable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step a:

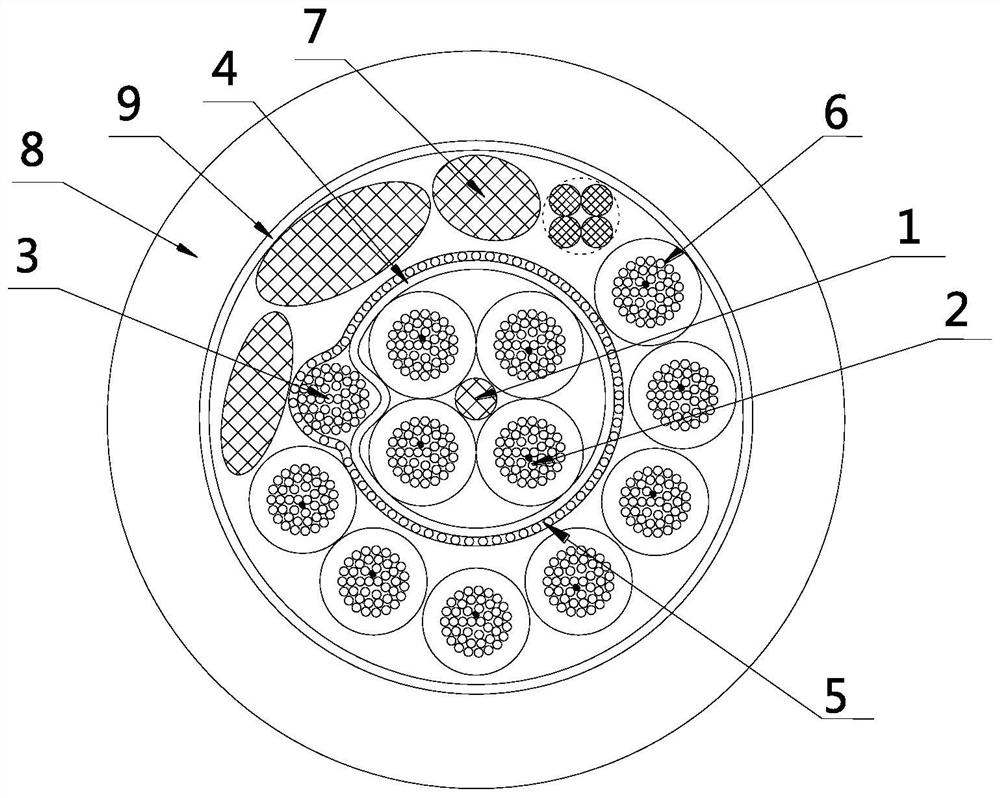

[0043] Inner conductor of inner core wire 2 and outer core wire 6: use 6 copper-tin alloy wires as the first layer, 200D Kevlar wire as the second layer, and 18*2 copper-tin alloy wires as the third layer. In addition, fluorine plastic is used as the insulating layer to extrude, and the whole body is extruded after online preheating in a 250°C oven.

[0044] Step b:

[0045] The inner core wires 2 are individually twisted and shielded: the four inner core wires 2 are directly untwisted and bundled, and then twisted around the inner Kevlar filler wire 1 to form a cable;

[0046] stepc:

[0047] Fabrication of the tape 4 and the shielding layer 5: wrap the upper tape 4 around the four inner core wires 2, wrap the upper shielding layer 5 on the outside of the tape 4, and bury the ground between the tape 4 and the shielding layer 5 line 3;

[0048] Step d:

[0049]Integral twisting and shielding: seven outer core wires 6 and multiple outer Kevlar filler wires...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com