Application of ion implantation technology in CCD fabrication and CCD fabrication technology

An ion implantation and process technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as large impurity non-uniformity, device parameters are difficult to meet standards, affecting CCD quality, etc., and achieve process improvement, performance and The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

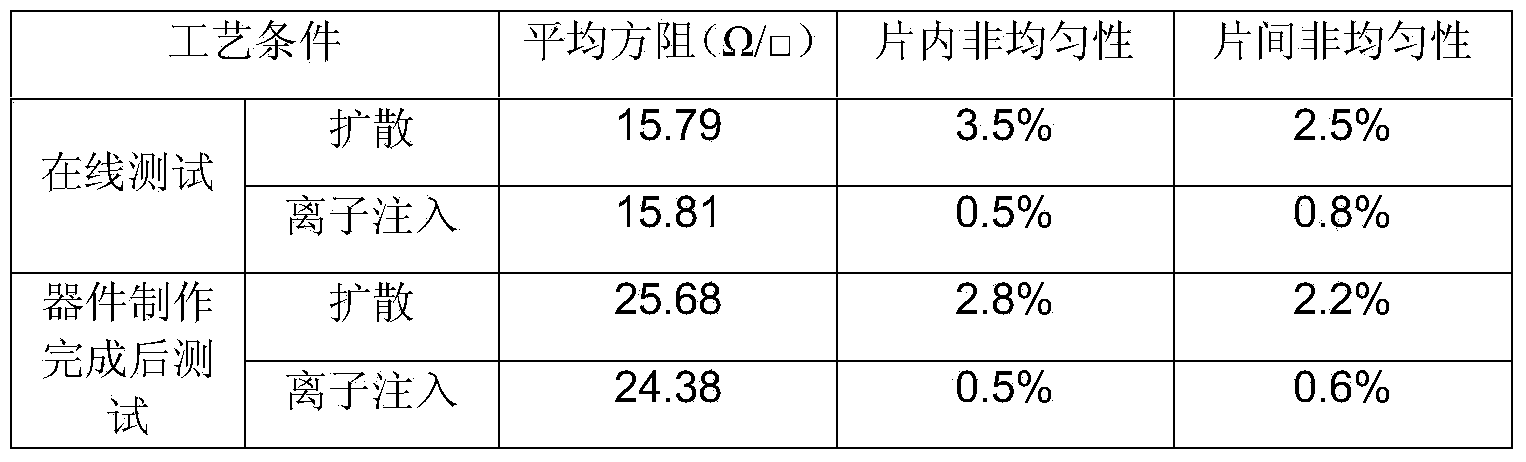

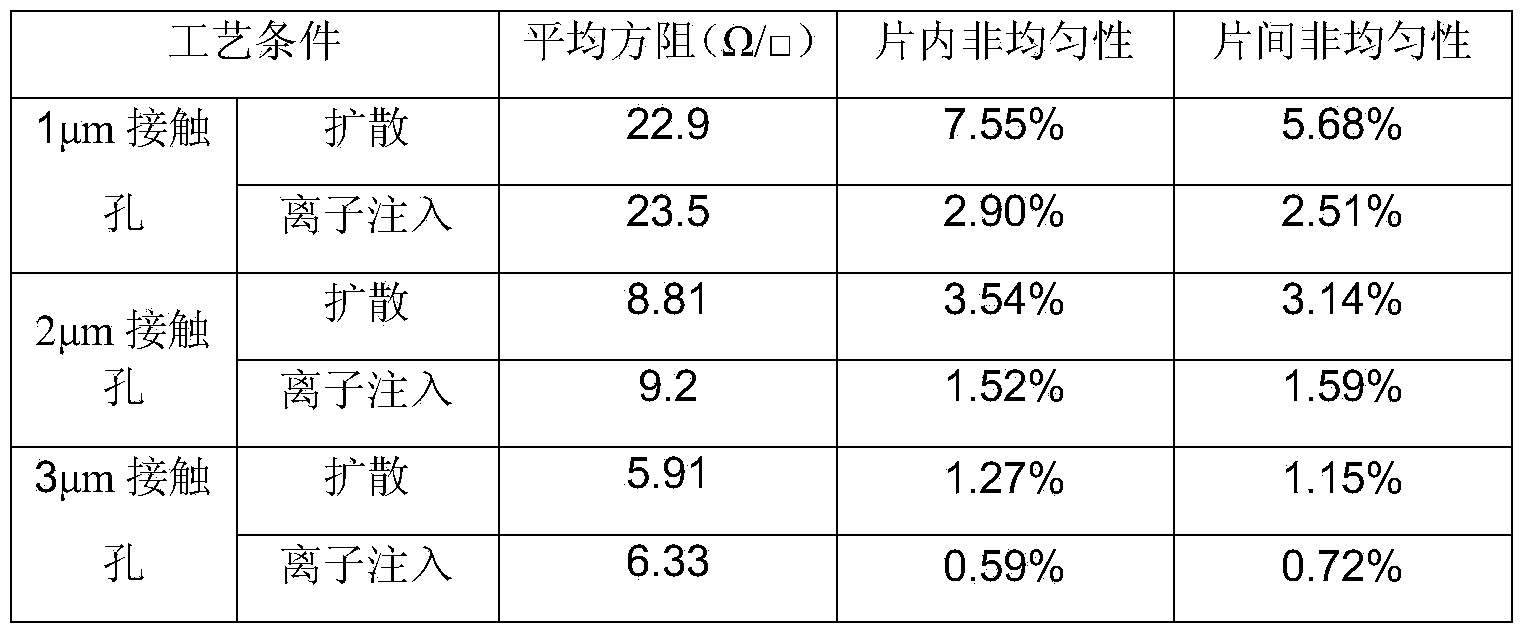

[0019] An application of an ion implantation process in the manufacture of a CCD, including: a conventional ion implantation doping process used for the manufacture of a polysilicon gate on other devices, the other devices being non-CCD devices, the innovation of which is: making a polysilicon gate on the CCD When the conventional ion implantation doping process is used, phosphorus ion implantation doping is performed on the polysilicon gate on the CCD.

[0020] Further, the conventional ion implantation doping process is implemented by an ion implanter.

[0021] A CCD manufacturing process, comprising: 1) gate oxidation, 2) silicon nitride deposition, 3) buried trench lithography, 4) buried trench implantation, 5) trench resist lithography, 6) trench resist implantation, 7) polysilicon Gate fabrication, 8) source-drain lithography, 9) source-drain doping, 10) contact hole lithography and etching, 11) metal deposition, 12) metal lithography and etching; wherein, step 7) includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com