Method for manufacturing high-precision fine lines on high-flatness surface of LTCC substrate

A production method and high-precision technology, applied in the fields of printed circuit manufacturing, cleaning/polishing of conductive patterns, secondary treatment of printed circuits, etc., can solve the problems of low adaptability of high-frequency LTCC materials, wire defects, and low yield. Achieve the effect of mature equipment and technology, high surface smoothness and small line fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

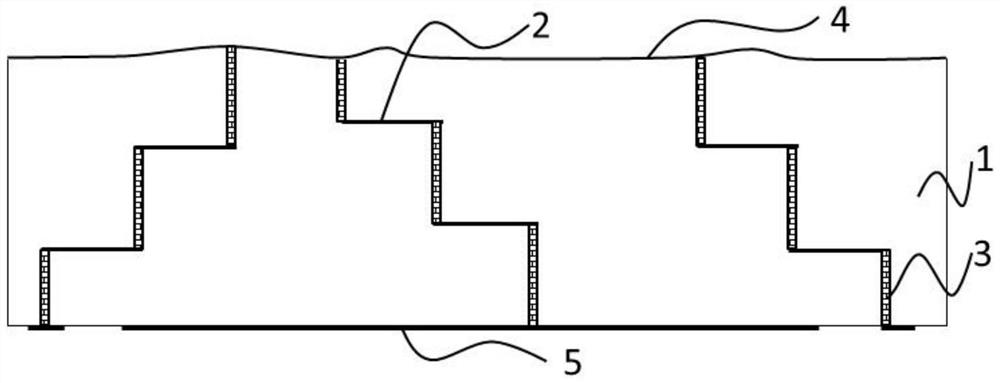

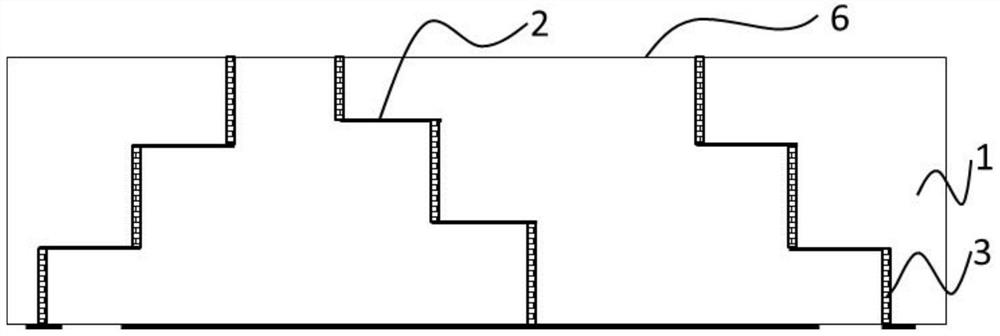

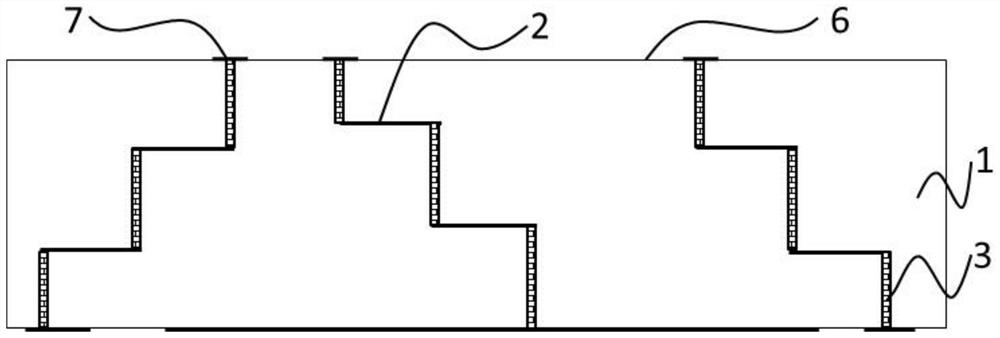

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The present invention relates to the processing of LTCC circuit substrates, especially to make high-precision fine lines on the high flat surface of LTCC substrates to obtain high surface flatness, line fineness and line precision, so as to meet the requirements of high-density chip reverse assembly, support Fabrication of SIP high-density multi-function package.

[0030] The surface of the LTCC multi-layer circuit substrate is high-flat by grinding, the surface is made of high-precision fine lines by laser etching, and the slag on the edge of the conductor pattern is cleaned by high-temperature post-processing. The specific production process is as follows:

[0031] A method for manufacturing high-precision fine lines on a high-level surface of an LTCC substrate, comprising the following processes:

[0032] Step 1, smoothing the surface of the sintered multila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com