A kind of asymmetric star-shaped styrene-butadiene rubber and its preparation method and application as sole rubber material

A styrene-butadiene rubber and asymmetric technology, which is applied to asymmetric star-shaped styrene-butadiene rubber and its preparation and application as a sole rubber material, can solve problems such as difficulty in stable production at the current stage, and achieve mature equipment and process operation, high resistance to The effect of good abrasiveness, excellent wet skid resistance and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

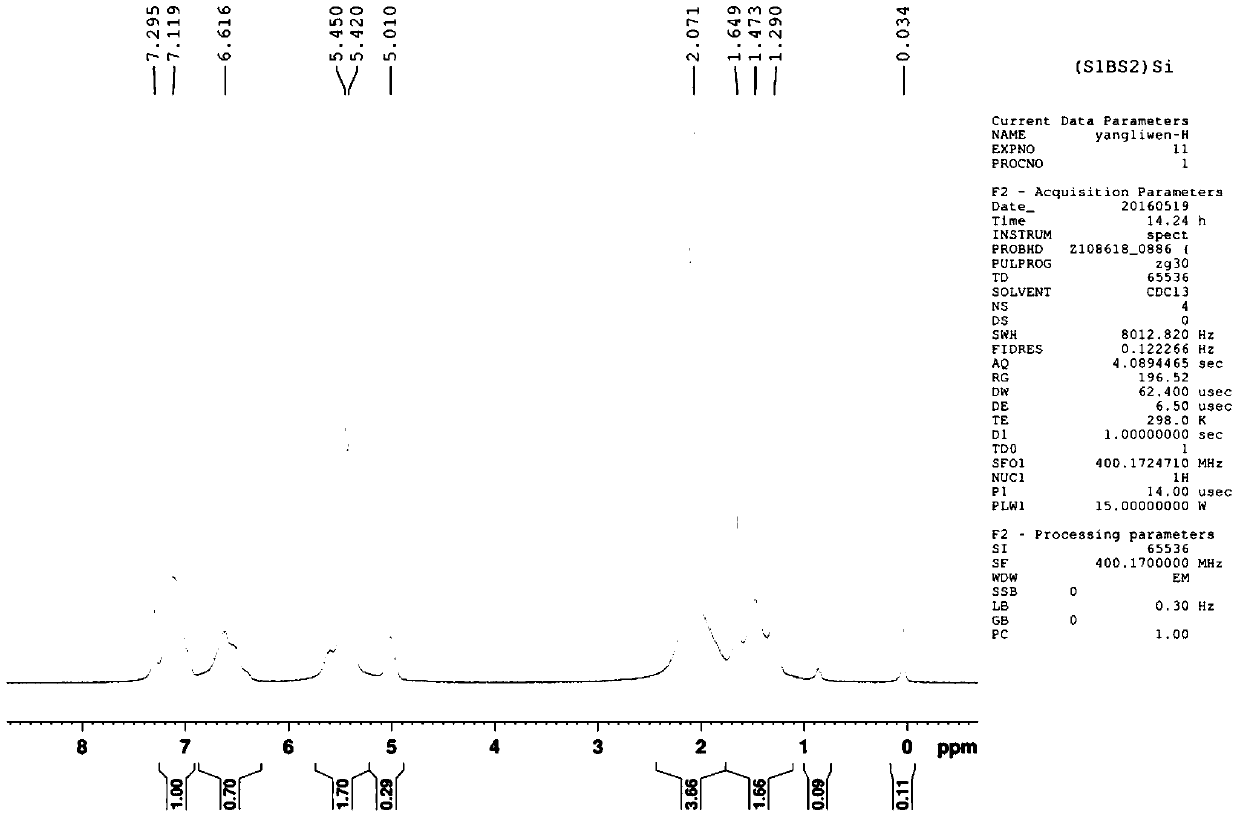

Image

Examples

Embodiment 1

[0052] In a jacketed 5L stainless steel magnetically stirred reactor, the system was replaced 3 times with nitrogen gas. Add 2000g of cyclohexane and 0.1mL of tetrahydrofuran to the polymerization kettle, stir and raise the temperature to 55°C, add 110.25g of styrene (S 1 Accounting for 36.75% of the total amount of monomers), a small amount of n-butyllithium was added several times until the solution was pale yellow, and 4.3mmol of n-butyllithium was added again, polymerized for 25min, and then 174g (accounting for 58% of the total amount of monomers ) Butadiene is added to the polymerization kettle, the reaction temperature is controlled at 50-110°C, and the reaction is carried out for 35 minutes, and then 15.75g of styrene (S 2 Accounting for 5.25% of the total amount of monomers) into the polymerization kettle to continue the reaction for 30 minutes, after the monomers are completely converted, the temperature is raised to 70 ° C, and 1.1 mmol SnCl is added 4 The coupling...

Embodiment 2

[0054] Other processing conditions and raw material addition are identical with embodiment 1, and difference is: the ratio of styrene twice addition is different, i.e. S 1 :S 2 The difference is 1.2:1, S1=68.73g, S2=57.27g, and the styrene rubber with the same structure as in Example 1 is obtained.

Embodiment 3

[0056] Other processing conditions are identical with embodiment 1, and difference is: styrene accounts for the different ratio of monomer total amount, is 20%, S 1 =52.5g, S 2 =7.5g, butadiene B=240g, the styrene rubber of the same structure as Example 1 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com