Quick-freezing method for keeping original quality of bamboo shoots

A technology of bamboo shoots and quality, applied in the field of quick freezing to maintain the original quality of bamboo shoots, can solve the problems of declining edible quality and damage to bamboo shoot fibers, etc., and achieve the effects of mature equipment, good economic value and huge commercial potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

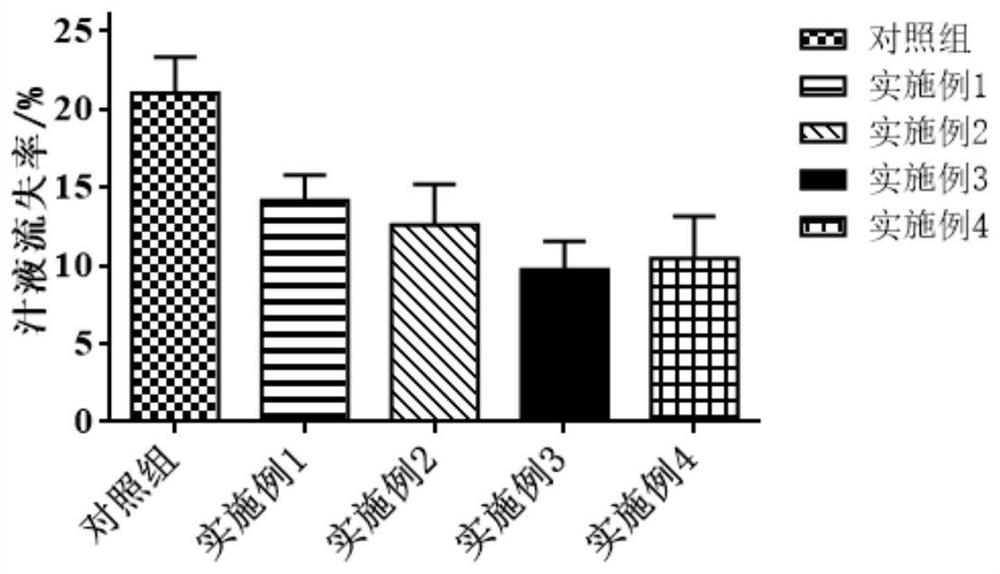

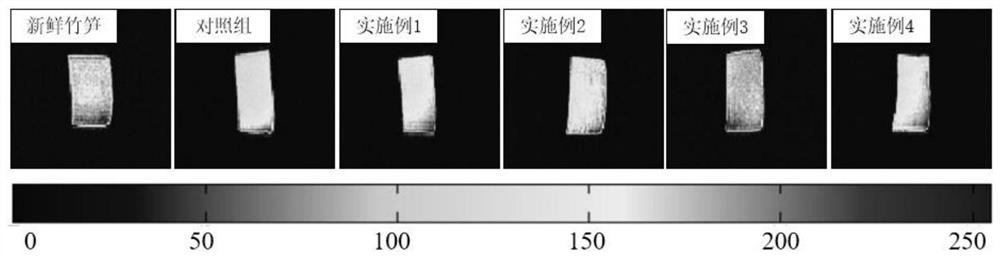

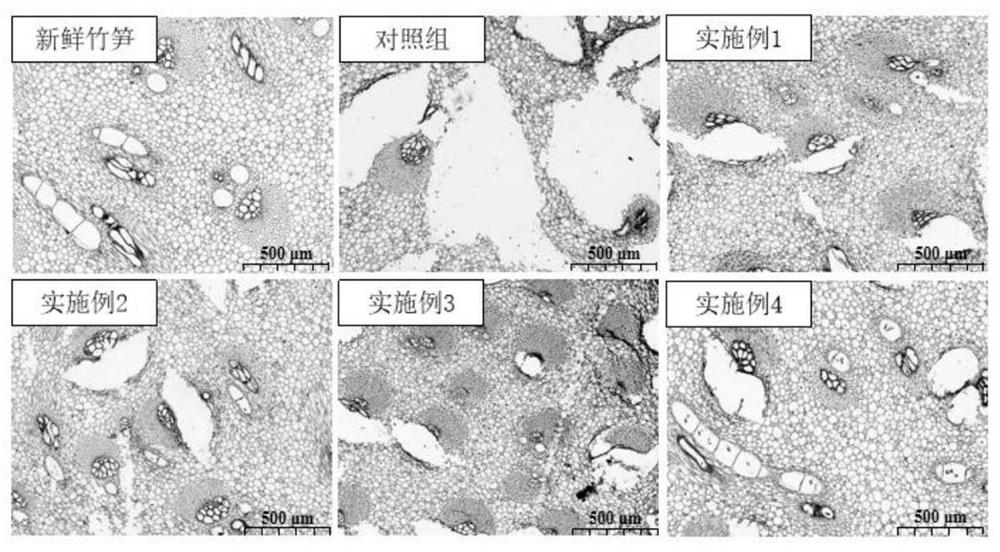

[0024] Because the traditional quick-freezing method seriously damages the bamboo shoot fiber and tissue structure, and the water loss rate of nutrients is large, in order to reduce the freezing damage of bamboo shoots and improve the quality of quick-frozen bamboo shoots, this embodiment provides a quick-freezing method that maintains the original quality of bamboo shoots. Proceed as follows:

[0025] ①Choose fresh bamboo shoots free from diseases and insect pests, clean them and put them in boiling water for 10 minutes to inactivate the activity of bamboo shoot enzymes and sterilize them to prevent fibrosis, oxidative discoloration and microbial contamination.

[0026] ② Peel off the shells of the blanched bamboo shoots, remove the skin of the bamboo shoots, and cut off the fibrous part of the base of the bamboo shoots to obtain edible bamboo shoots.

[0027] ③Soak edible bamboo shoots in the freezing pretreatment solution at 42±2°C for 15 minutes. The freezing pretreatment ...

Embodiment 2

[0032] Because the traditional quick-freezing method seriously damages the bamboo shoot fiber and tissue structure, and the water loss rate of nutrients is large, in order to reduce the freezing damage of bamboo shoots and improve the quality of quick-frozen bamboo shoots, this embodiment provides a quick-freezing method that maintains the original quality of bamboo shoots. Proceed as follows:

[0033] ①Choose fresh bamboo shoots free from diseases and insect pests, clean them and put them in boiling water for 10 minutes to inactivate the activity of bamboo shoot enzymes and sterilize them to prevent fibrosis, oxidative discoloration and microbial contamination.

[0034] ② Peel off the shells of the blanched bamboo shoots, remove the skin of the bamboo shoots, and cut off the fibrous part of the base of the bamboo shoots to obtain edible bamboo shoots.

[0035] ③Soak edible bamboo shoots in the freezing pretreatment solution at 42±2°C for 15 minutes. The freezing pretreatment ...

Embodiment 3

[0040]Because the traditional quick-freezing method seriously damages the bamboo shoot fiber and tissue structure, and the water loss rate of nutrients is large, in order to reduce the freezing damage of bamboo shoots and improve the quality of quick-frozen bamboo shoots, this embodiment provides a quick-freezing method that maintains the original quality of bamboo shoots. Proceed as follows:

[0041] ①Choose fresh bamboo shoots free from diseases and insect pests, clean them and put them in boiling water for 10 minutes to inactivate the activity of bamboo shoot enzymes and sterilize them to prevent fibrosis, oxidative discoloration and microbial contamination.

[0042] ② Peel off the shells of the blanched bamboo shoots, remove the skin of the bamboo shoots, and cut off the fibrous part of the base of the bamboo shoots to obtain edible bamboo shoots.

[0043] ③Soak edible bamboo shoots in the freezing pretreatment solution at 42±2°C for 15 minutes. The freezing pretreatment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com