Composite negative electrode material for lithium ion battery, and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the field of lithium-ion batteries, can solve the problems of high rate continuous charge and discharge capacity and low temperature performance, low specific capacity of graphite negative electrode, etc., to achieve excellent cycle performance, improve rate, increase The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

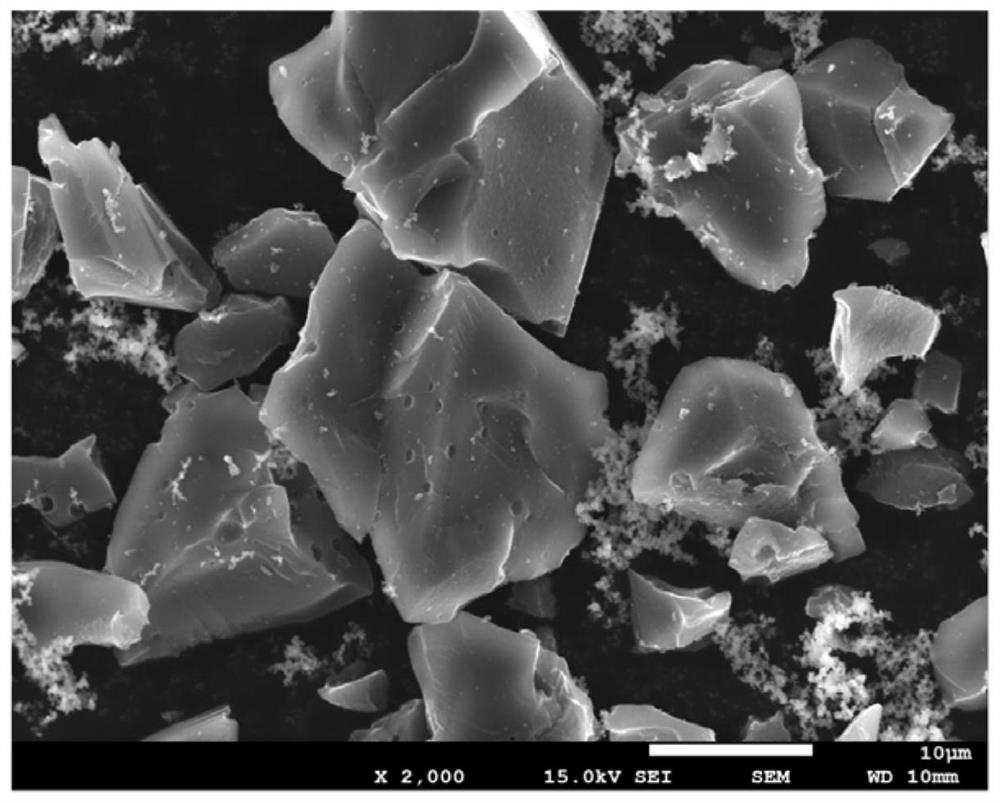

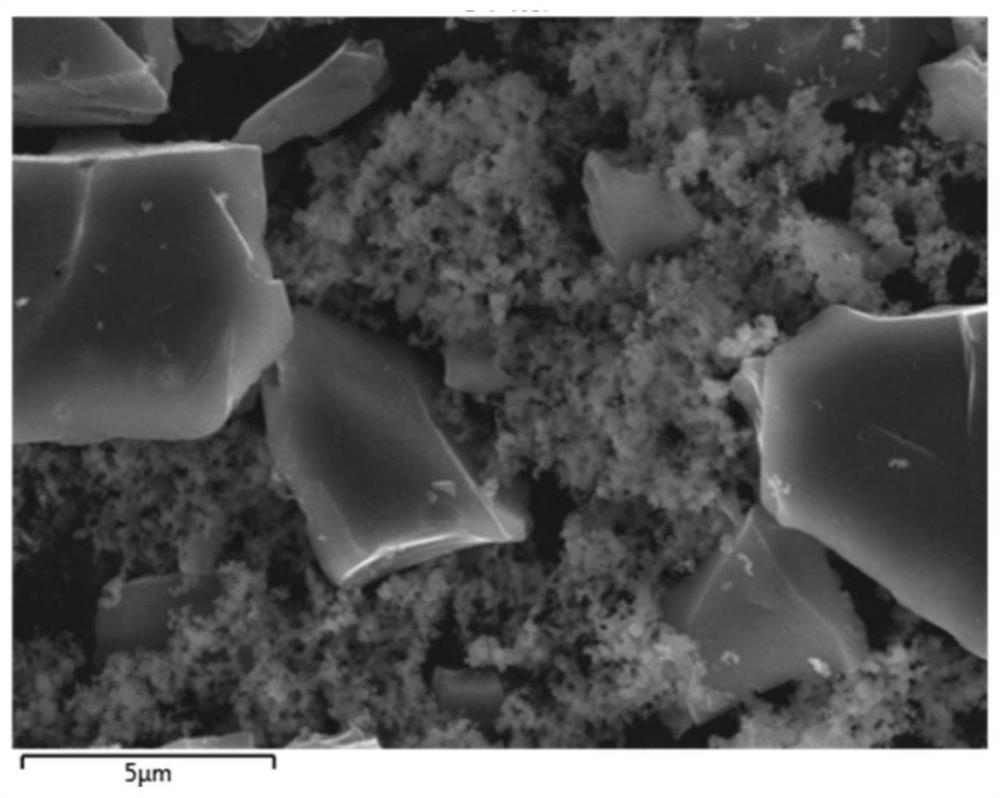

Image

Examples

preparation example Construction

[0043] In the embodiment of the present application, the present invention also provides a preparation method of a composite negative electrode material for a lithium ion battery, the composite negative electrode material includes the composite negative electrode material for a lithium ion battery as described above, and the method includes the steps :

[0044] Prepare carbonaceous material precursors, silicon particles and carbon source materials;

[0045] Sintering the carbonaceous material precursor at a low temperature of 300°C-500°C for 2h-5h in an inert gas environment to obtain the first fired material;

[0046] Soaking the first burnt material with dilute hydrochloric acid, then washing the first burnt material with pure water until the pH value of the soaking solution is 6-8, and obtaining the first purified material;

[0047] Sintering the first purified material at a high temperature of 1000°C-1300°C for 2h-5h in an inert gas environment to obtain a second burnt ma...

Embodiment 1

[0057] In the embodiment of the present application, the preparation method of a composite negative electrode material for a lithium-ion battery provided by the present application specifically includes the following steps:

[0058] (1) Get 1kg of coarse coconut shell material (carbonaceous material precursor) and place it in a box-type furnace, feed nitrogen until the oxygen content in the box-type furnace is lower than 100ppm, and then heat up to 300°C at 3° / min. ℃, calcined for 5 hours, and obtained 0.34 kg of burnt material. The burned material is placed in dilute hydrochloric acid, washed repeatedly to remove impurities, and then rinsed with pure water until the pH value of the solution is 6-8, and then dried. The dried material was placed in a box furnace, and nitrogen gas was introduced until the oxygen content in the box furnace was lower than 100ppm, then the temperature was raised to 1300°C at 3° / min, and sintered for 2 hours. The burned material is crushed, and the...

Embodiment 2

[0063] The difference from Example 1 is that the carbonaceous material precursor in step (1) is phenolic resin, the low-temperature sintering temperature is 350°C, and the sintering is 4h; the high-temperature sintering temperature is 1200°C, and the sintering is 3h; ±1 μm, to obtain carbonaceous materials.

[0064] Step (2) uses liquid phase compounding, adding carbonaceous material and silicon oxide into the ethanol solution at a mass ratio of 8:2, stirring evenly, and then drying to obtain composite powder.

[0065] The carbon source gas used in step (3) is acetylene, the treatment temperature is 800°C, and the content of deposited carbon is controlled to be 10wt.%, to obtain a composite negative electrode material.

[0066] In the composite negative electrode material, the proportion of carbonaceous material is 72.0wt.%, the proportion of silicon particles is 18wt.%, and the proportion of coated carbon is 10wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com