Constant-volume container and using method thereof

A container and constant volume technology, applied in the field of volume measurement, can solve the problems of low measurement accuracy, many error factors, poor repeatability, etc., and achieve the effect of simple cleaning process, simple operation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 constant volume container of the present invention

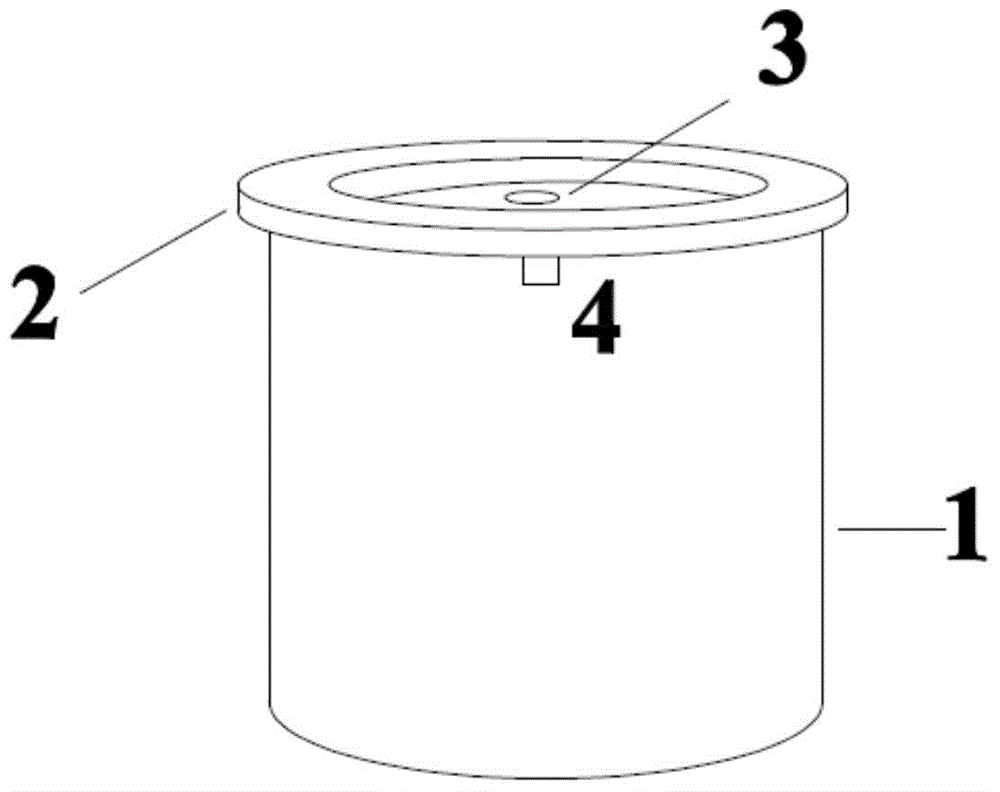

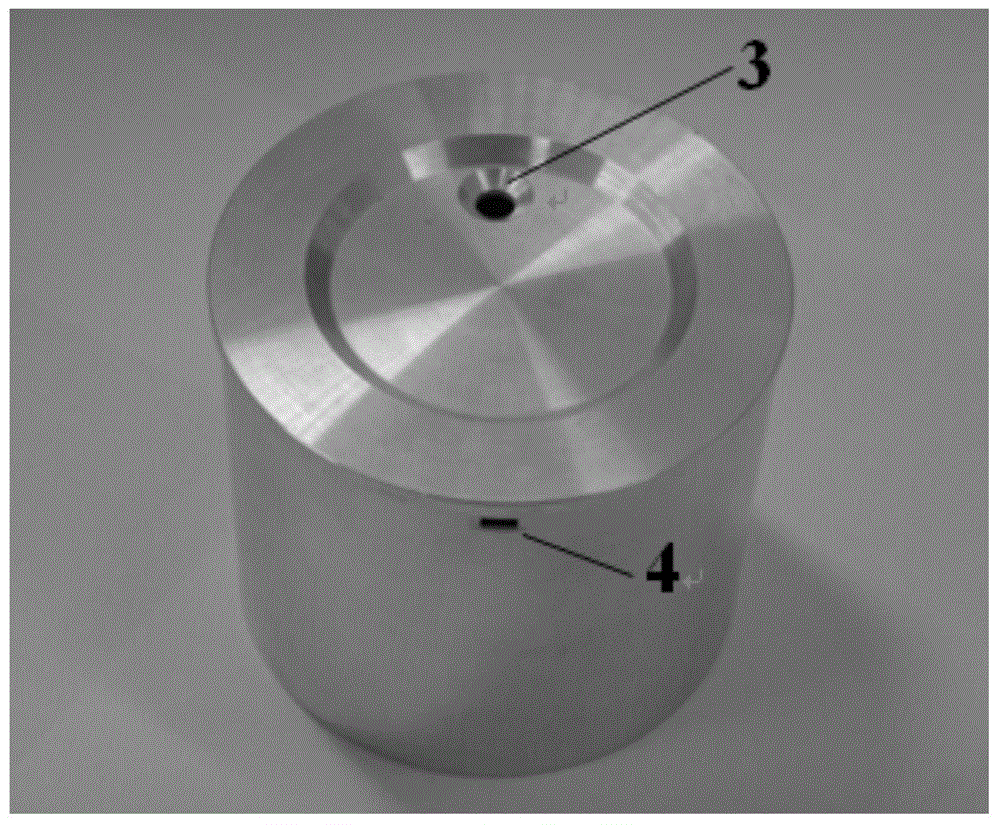

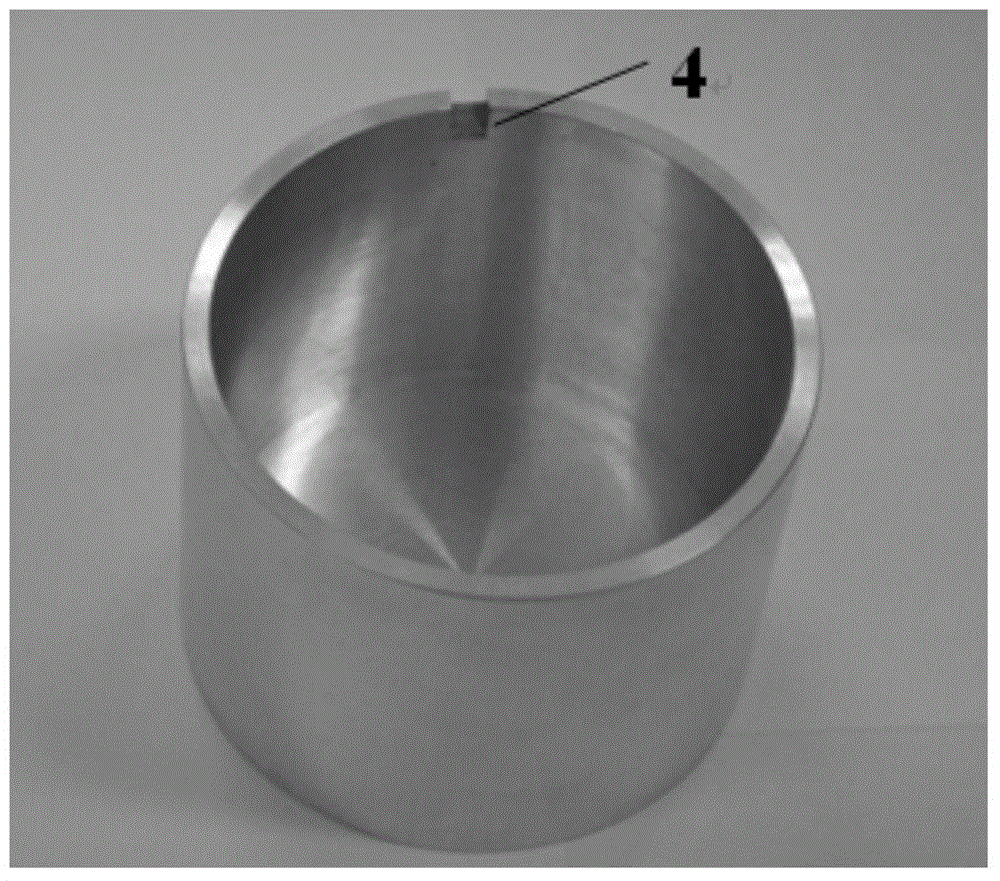

[0033] The structure diagram of the constant volume container (including the constant volume container 1 and the constant volume container cover 2 without the liquid level positioning cover) of the present invention is as follows figure 1 As shown in the real photo figure 2 , 3 , 4. The constant volume container 1 with the liquid level positioning cover removed is a cylindrical container, the liquid level positioning cover 2 is provided with a water injection port 3, and the container mouth is provided with an overflow port 4.

[0034] The constant volume container of this embodiment has an inner diameter of 75 mm, an outer diameter of 81 mm, a height of 63 mm, a wall thickness of 3 mm, and a liquid level positioning cover of 3 mm in thickness. The overflow port 4 is 3 mm deep and 5 mm wide, and is cut inward at 45°; the lower port diameter of the water injection port 3 is 2 mm, and the upper port dia...

Embodiment 2

[0036] Embodiment 2 uses the equipment used when the volume of the constant volume container of the present invention is measured

[0037] The structure diagram of the equipment used when using the constant volume container of the present invention to measure the volume is as Figure 5 As shown, it includes a constant volume container (see Example 1), a weighing device 5, an electronic balance (Shanghai Zhuojing Electronic Technology Co., Ltd., model: BSM-5200.2), a water injection device dropper 6 (common glass glue commonly used in laboratories head dropper).

Embodiment 3

[0038] Embodiment 3 Determination of the constant volume container volume of the present invention

[0039] See Example 2 for the equipment used.

[0040] To determine the volume of a constant volume container:

[0041] Take an appropriate amount of distilled water and pour it into a constant volume container. When the injected water is close to filling the container, cover the constant volume container with a liquid level positioning cover, and then continue to slowly add distilled water through the water injection port on the liquid level positioning cover until the constant volume Stop when water drops appear at the overflow at the upper end of the side wall of the container. Then wipe off the remaining water stains on the container wall with absorbent paper, and then place it on an electronic scale for weighing. At 4°C, the density of water is 1.000g / cm 3 , in the case of little temperature change, the density of water can be approximated as 1.000g / cm 3 . The volume o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com