Oil-gas separation device for transformer insulation oil

A technology for transformer insulating oil and separation device, which is applied in measurement devices, separation methods, instruments, etc., can solve the problems of long data collection time, air mixing, and unreliable judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

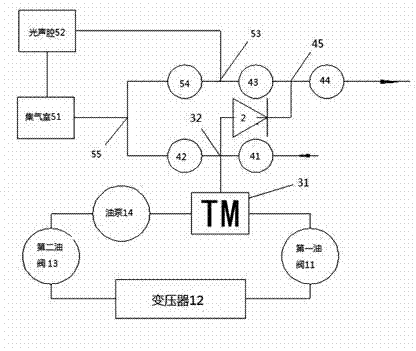

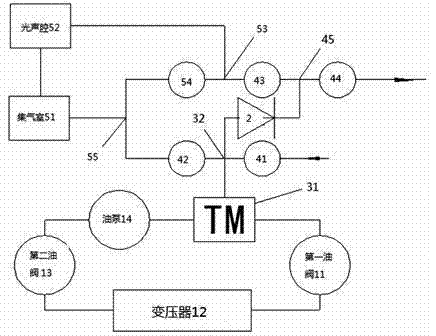

[0026] Combine below figure 1 An oil-gas separation device for transformer insulating oil of the present invention will be further elaborated, and a preferred embodiment of the present invention will be described in detail.

[0027] Such as figure 1 As shown, an oil-gas separation device for transformer insulating oil includes an oil-discharging component, an air pump 2 connected through a gas pipe, a degassing module, a solenoid valve group component, and a gas collection detection cycle component; the described oil-discharging component includes a The first oil valve 11, the transformer 12, the second oil valve 13 and the oil pump 14 connected in turn by the oil pipe; the inlet of the first oil valve 11 is connected with the oil outlet of the sealed cavity 31; the outlet of the oil pump 14 is connected with the sealing The oil inlets of the cavity 31 are connected to each other.

[0028] The degassing module includes a sealed cavity 31 and a polymer microporous capillary i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com