Medium-deep hole construction and blocking treatment method in large fault section of sublevel caving method without bottom pillar

A segmented caving method and construction method technology, which is applied in the field of underground mining, can solve the problems of affecting the blasting effect, prone to clamping, and large safety risks, so as to ensure the blasting effect, avoid safety risks, and reduce the charge amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 Medium and deep hole construction

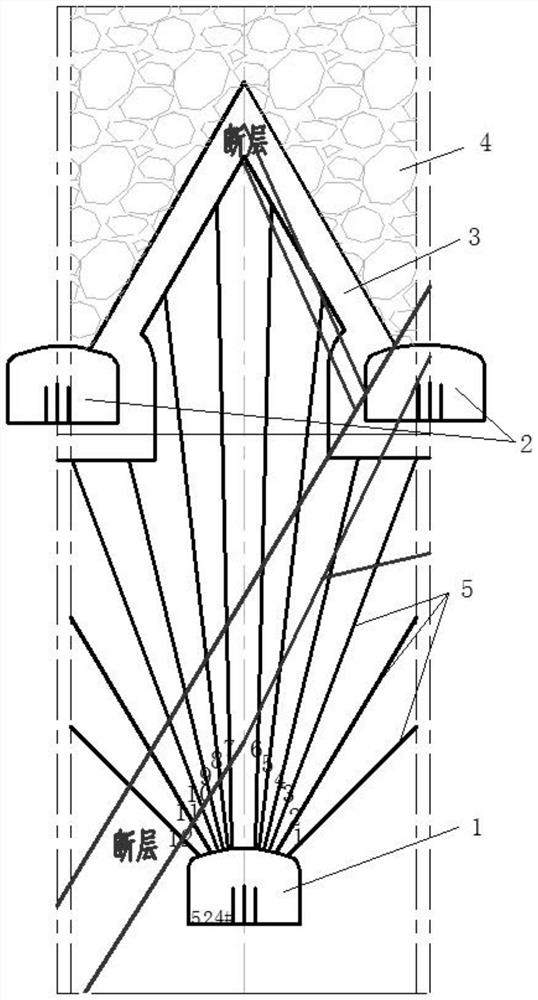

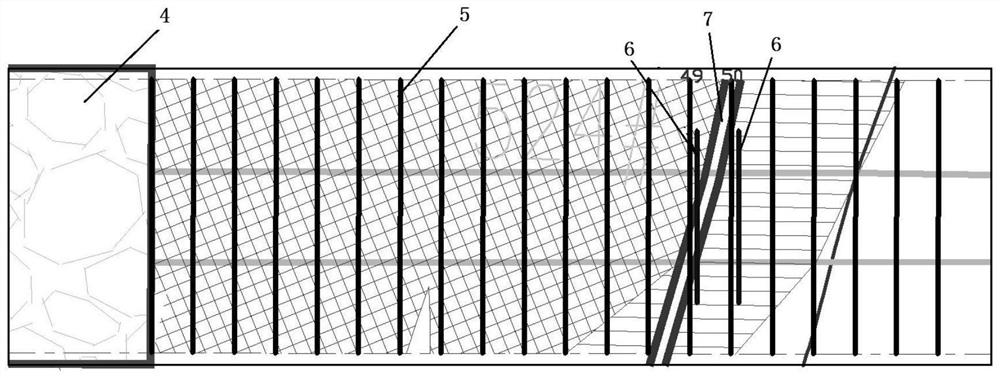

[0049]The mining area of the Dahongshan Iron Mine is mined by the high-segment, large-spacing and non-bottom-pillar segmental caving method in the upper and lower mining areas. The eastern footwall of the 340m segment is at the junction of the ore and rock, and is damaged by the FII-1 large fault. Blasting passes through this When it is in a weak rock formation zone, the problem of hole blocking is very likely to occur. The hole blocking will lead to poor blasting effect, and the situation of vertical walls and suspended ceilings will easily occur. The 49th and 50th rows of the 524 approach road in the eastern footwall of the 340m section are just at the position of the FII-1 major fault. The distance between the middle and deep holes 5 is 2.6mm, the hole diameter is 76mm, and the depth is 25mm. The explosive filling amount of the middle and deep holes 5 in a single row is 1800Kg.), offset 0.3m to the east and make up 4...

Embodiment 2

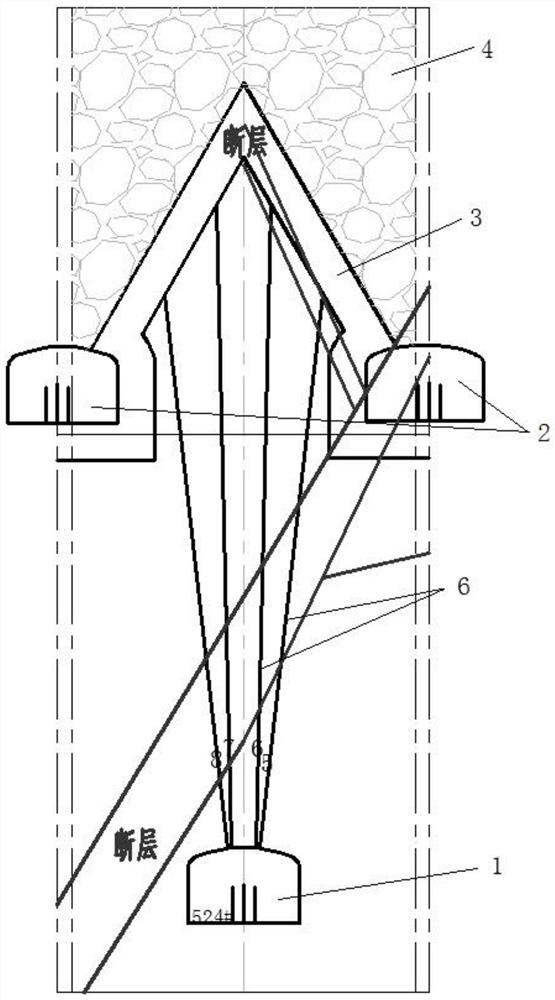

[0050] Embodiment 2 Clogging treatment

[0051] When the 340m sub-section 657 route blasted to the 5th row in the upper and lower mining area of Dahongshan Iron Mine, affected by the fault and blasting vibration, the browline hole span was high and the hole damage was serious (4 key deep holes were blocked), which did not meet the requirements. The blasting conditions or the probability of roof overhang after blasting are extremely high. The actual measurement shows that the blockage depth is about 10m. According to the geological conditions of the site and the mine section, it is judged that the fine slag in the fault is blocking the hole, so the method of blowing the hole with high-pressure air is used to deal with it, such as figure 2 , 2 deep holes were dealt with, but there were still 2 deep holes not connected, and the blocked positions of the two holes were both at about 12m. In order to ensure the blasting effect and reduce the large block rate, the detonator 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com