Automatic membrane tearing device of OLED membrane and membrane tearing process thereof

A technology of membrane devices and membranes, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., and can solve problems such as vacuum damage, interrupted film tearing, and vacuum leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

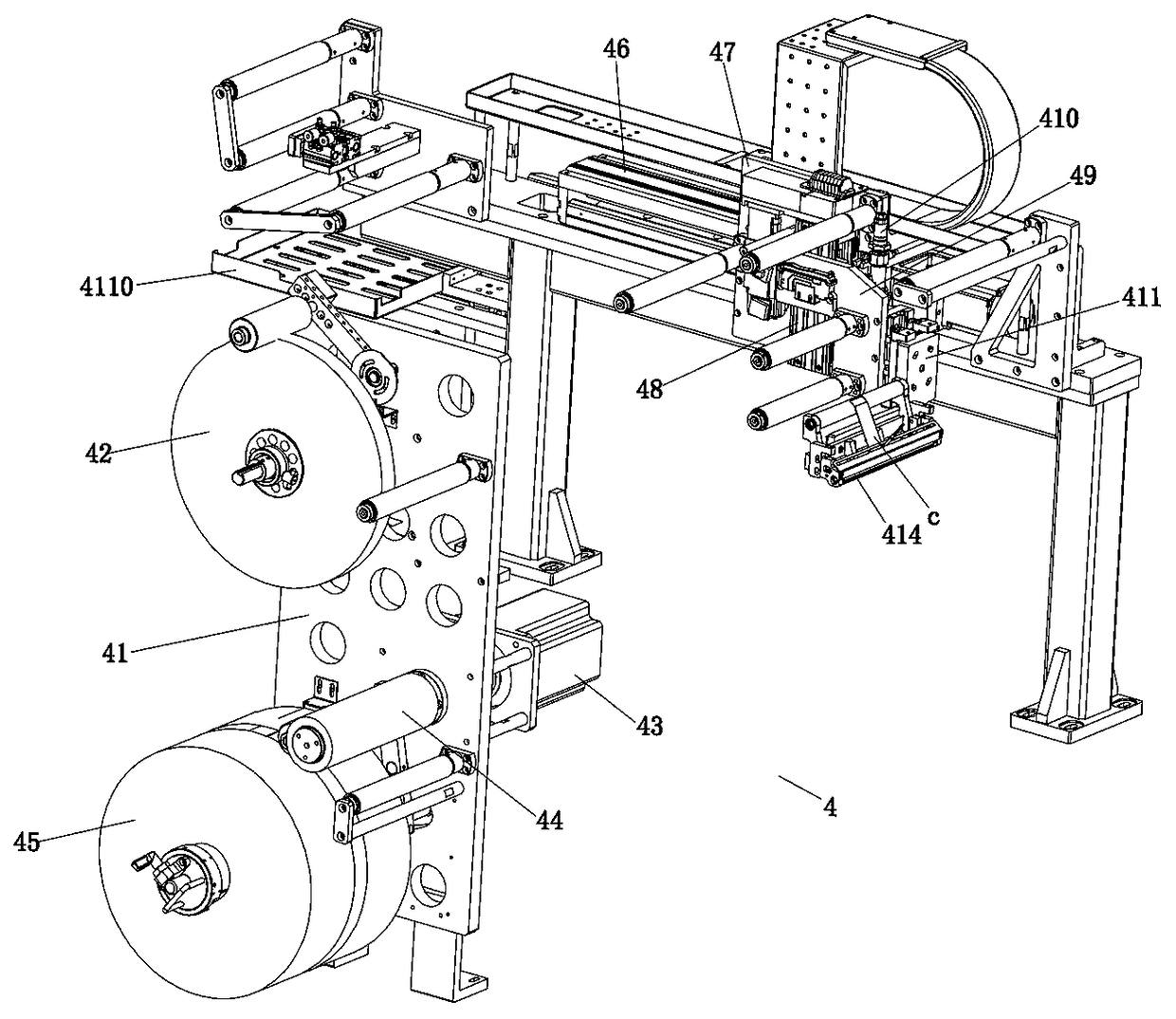

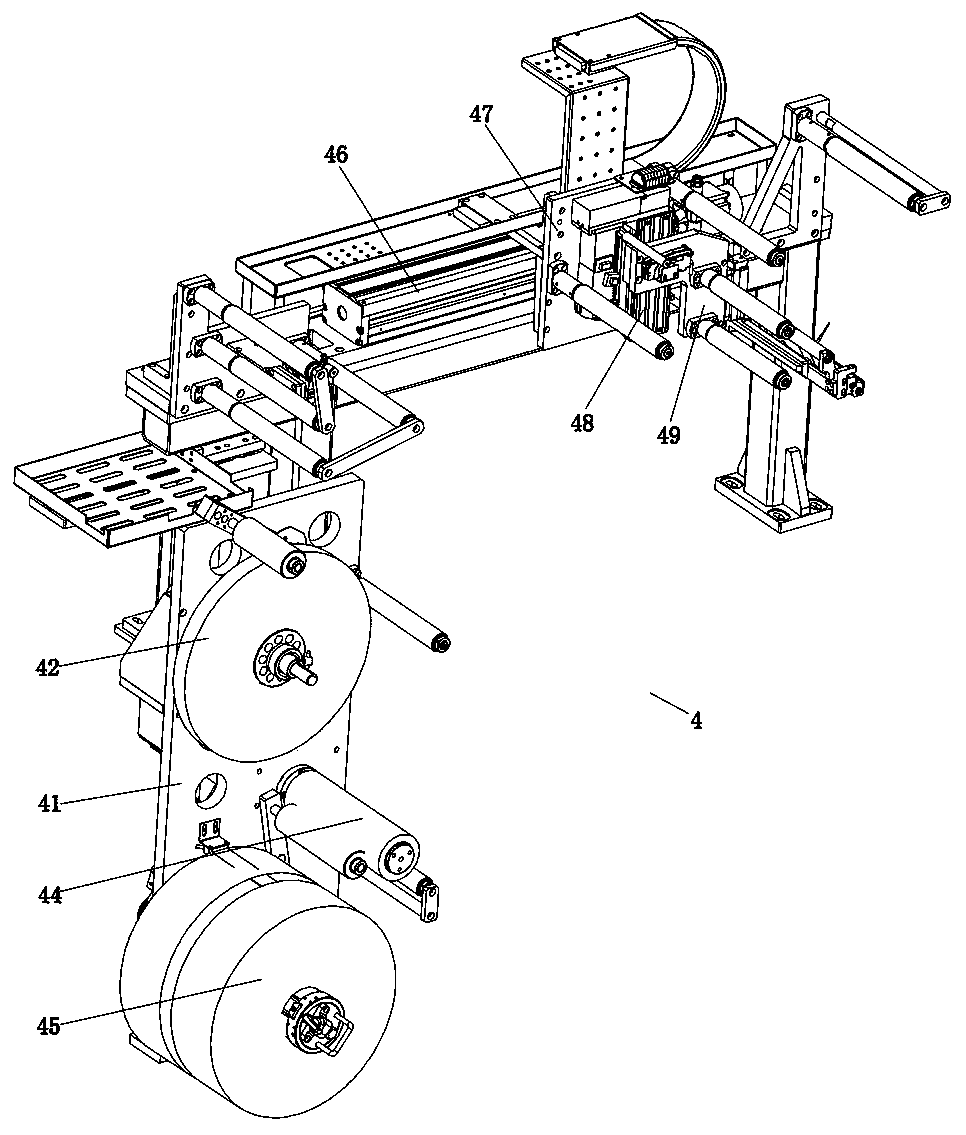

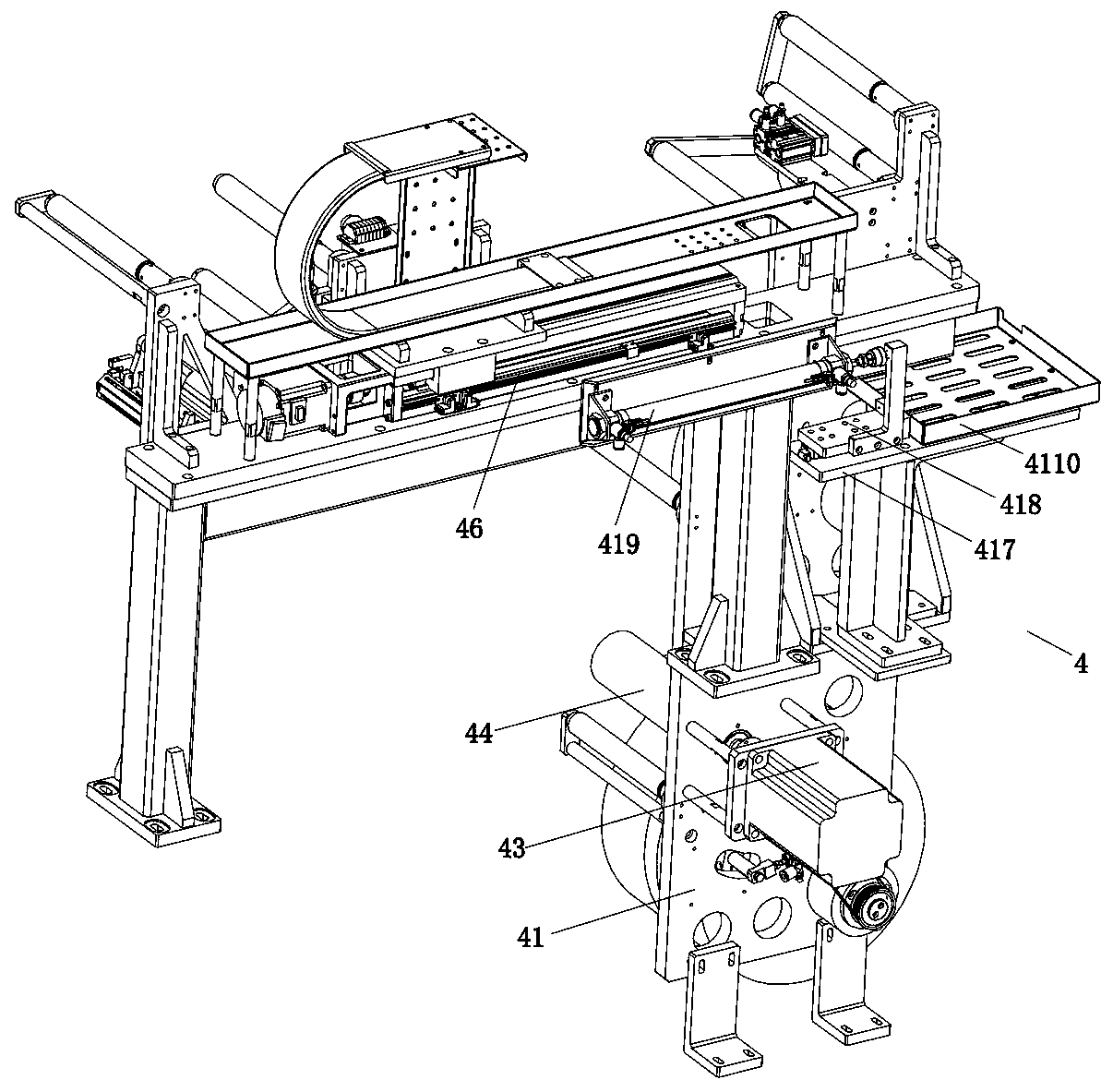

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] Such as Figure 1 to Figure 10 As shown, the technical solution adopted by the present invention is as follows: an automatic film tearing device for OLED film, which is set in a soft-to-soft laminating machine, and is used to automatically tear off the surface film body of the OLED film, including the first tape exporting assembly . OLED tear film assembly and waste film collection assembly, wherein, the above-mentioned first tape export assembly is arranged in the installation space at the front end of the frame, and the first tape export assembly pulls out the rolled first tear film tape c; the above The OLED tearing film assembly can be linearly slidably set above the first tape exporting assembly, and extends horizontally to the top of the OLED adsorption and transfer platform. The first tearing film tape c passes through the OLED tearing film assembly, with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com