Ultramicro rectangular electric connector and manufacturing method thereof

A technology for electrical connectors and manufacturing methods, which is applied in the direction of connection, contact manufacturing, and parts of connecting devices, etc., and can solve problems such as large contact spacing, connector spacing, small row spacing, and large connector spacing. , to achieve the effects of reduced row spacing, low sintering temperature and strong fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

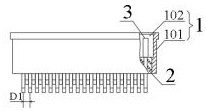

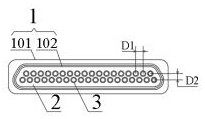

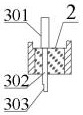

[0045] Such as Figure 1 to Figure 4 As shown, the ultra-micro rectangular electrical connector includes a housing 1, a glass base 2 and a plurality of socket contacts 3, and adopts a glass paste filling and sintering process, making full use of the glass paste with strong fluidity and low sintering temperature. Features, can significantly reduce the row distance of the connector, the shell and socket contacts are made of alloy materials, sintered with glass DM308 as a whole, and the leakage rate is not greater than 1.01×10 -3 Pa·cm 3 / S interface seal, figure 1 Among them, the outside of the housing 1 is a stepped rectangular structure 101, and the inside of the housing 1 is a trapezoidal stepped hollow structure 102. A plurality of socket contacts 3 are installed on the glass base 2 in a double row layout, and each row of socket contacts The spacing D1 of 3 is 0.74-0.76mm, and the row spacing D2 of two rows of socket contacts 3 is 0.64-0.66mm.

[0046] In this embodiment,...

Embodiment 2

[0051] In this embodiment, the manufacturing method of the ultra-micro rectangular electrical connector includes the following process steps:

[0052] 1) Soak the housing 1 and jack contact 3 in deionized water for 2-3 hours, then put the housing 1 and jack contact 3 into a filter container, rinse with deionized water, and then rinse with deionized water. Hydroalcoholic dehydration. Preferably, the metal parts (housing, socket) are soaked in deionized water for 2 hours, then put into a filter container, rinsed with deionized water, and then dehydrated with absolute alcohol.

[0053] 2) Put the shell 1 and the socket contact 3 into the vacuum furnace. After the furnace temperature rises to 900-1100°C, the holding time is 40-50min, and the vacuum degree in the vacuum furnace is 6.9×10 -2 -7.1×10 -2 Pa, clean the surface of the shell 1 and the socket contact 3; preferably, put the metal parts into a vacuum furnace, the temperature of the furnace rises to 950-1050°C, the holding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com