In-situ calibration device for large-size 3D space measurement and its measuring method

A three-dimensional space, on-site calibration technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of affecting the measurement accuracy, large aiming error, and theodolite cannot be aimed at each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

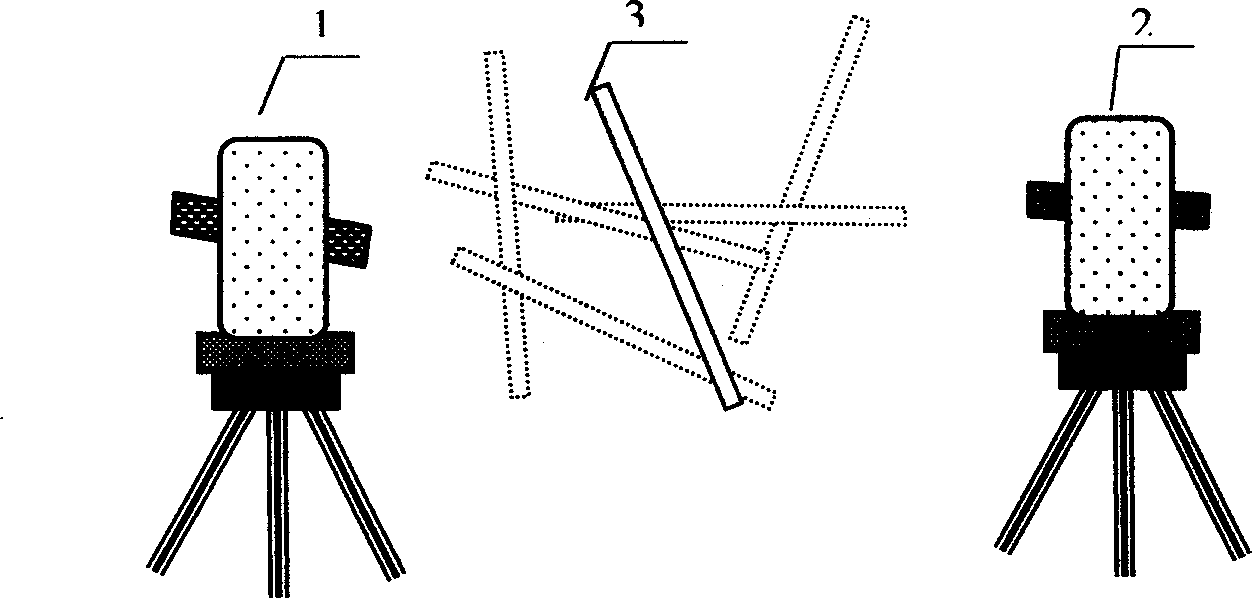

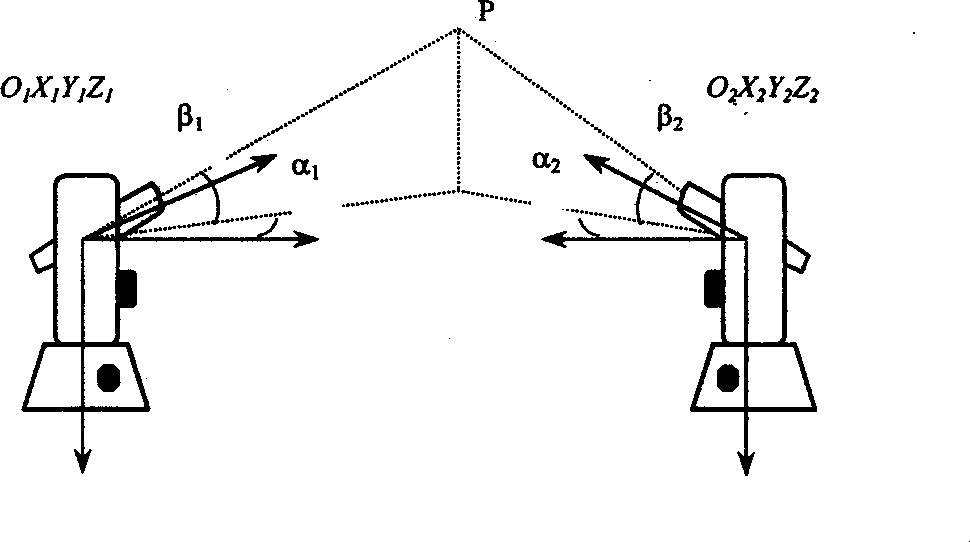

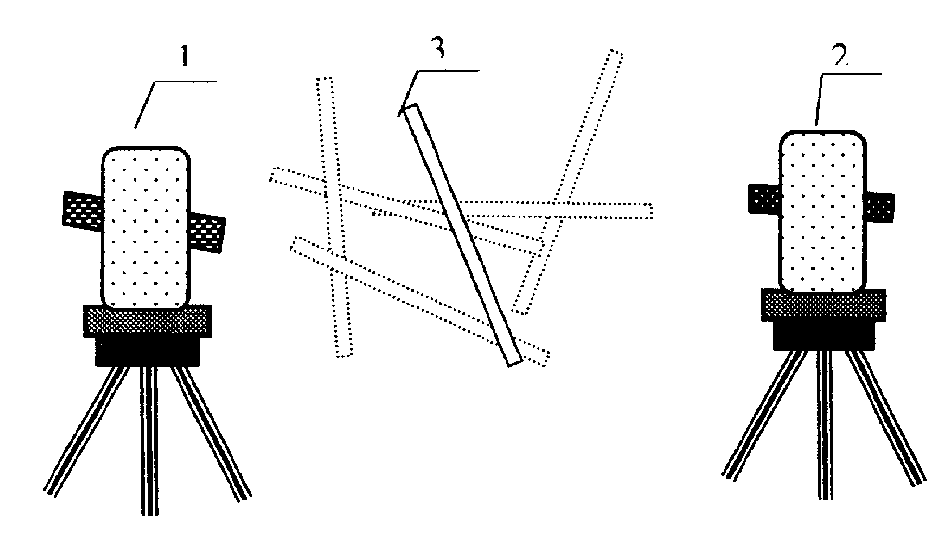

[0024] Such as figure 1 Shown: Place a standard ruler 3 with a known reference distance d in the measurement space, use two theodolites 1 and 2 to observe the cross marks (mark points) on the standard ruler at the same time, use the marked points and the reference distance on the standard ruler As a constraint condition, a constraint equation including the spatial position relationship parameters of the two theodolites is established. Changing the position of the standard ruler in the measurement space more than 6 times, a total of multiple constraint equations were obtained, and the optimization method was used to solve the obtained constraint equations, and the spatial position relationship parameters R and T of the two theodolites were obtained. By substituting the model parameters into the theodolite measurement model, the precise measurement of the three-dimensional coordinates of the space point can be realized, and there is no need to manually participate in the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com