Method and system for calibrating external parameters based on camera and three-dimensional laser radar

A camera coordinate system, three-dimensional laser technology, applied in the field of cameras and three-dimensional lidar, can solve the problems of not considering the error of the intermediate quantity, not considering the measurement error, the calibration of the external parameter rotation matrix R is not accurate enough, etc., to achieve accurate results, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

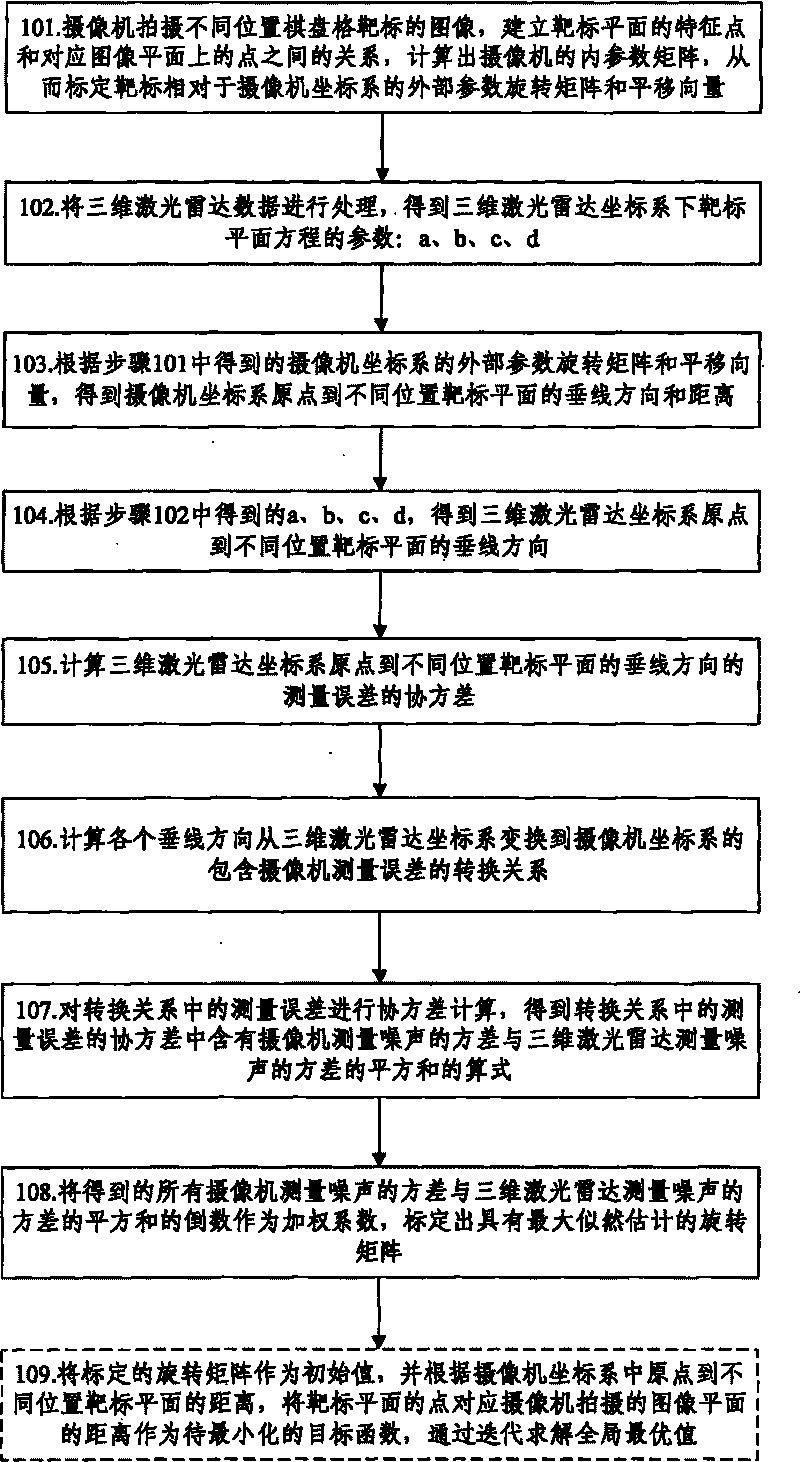

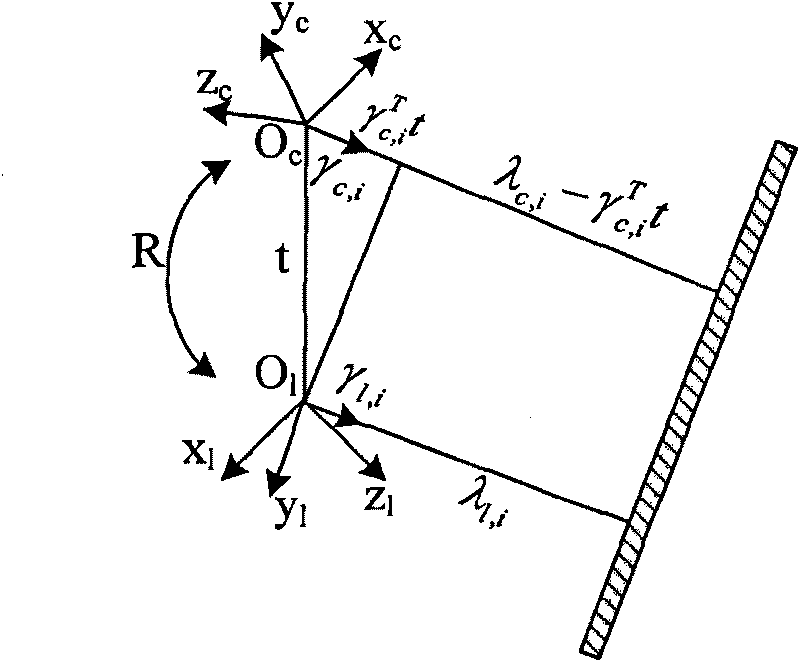

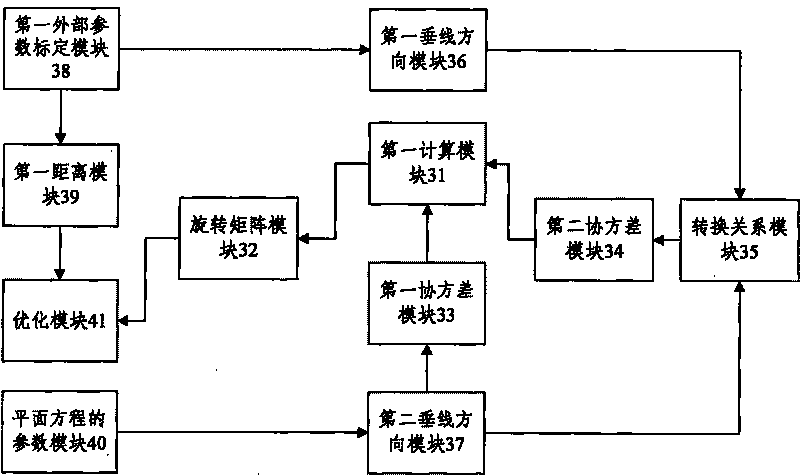

[0043] The basic idea of the present invention is: according to the covariance of the measurement error from the origin of the three-dimensional laser radar coordinate system to the vertical direction of the target plane at different positions, and the measurement error in the conversion relationship of the vertical direction from the three-dimensional laser radar coordinate system to the camera coordinate system The covariance of the measurement error in the conversion relationship contains the formula of the sum of the squares of the variance of the camera measurement noise and the variance of the three-dimensional laser radar measurement noise. The reciprocal of the sum of squared variances is used as a weighting coefficient to calibrate the rotation matrix with maximum likelihood estimation.

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The present invention realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com