Calibration compensation method for triaxial vector sensor and biaxial vector sensor

A compensation method and sensor technology, applied in the direction of measuring electrical variables, testing/calibration of speed/acceleration/shock measurement equipment, instruments, etc., can solve problems such as difficult implementation, high equipment requirements, and complicated methods

Inactive Publication Date: 2010-11-17

ZHONGBEI UNIV

View PDF0 Cites 57 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problems that the existing multi-axis vector sensor calibration compensation method does not take into account all the factors causing the measurement error, and the method is complicated, difficult to implement, and has high requirements for equipment, it provides a simple correction process and accurate correction results. Calibration compensation method of three-axis vector sensor and two-axis vector sensor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

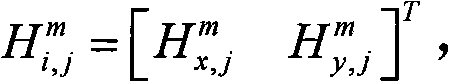

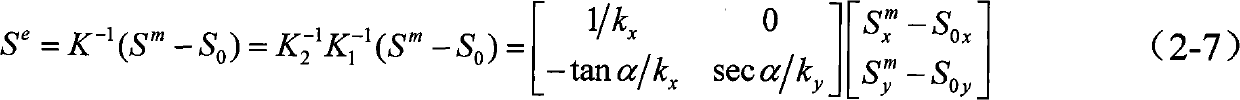

The invention relates to error correction of a vector sensor, in particular to a calibration compensation method for a triaxial vector sensor and a biaxial vector sensor, and solves the problems that the calibration compensation method of the existing multi-axial vector sensor fails to take all factors causing measurement error into account and the like. In the method, an error correction mathematical model of the vector sensor is built according to the relation of actually measured output Sm and theoretical output Se of the vector sensor, i.e. Sm=KSe + S0 and according to an error coefficient matrix K=K1K2, wherein, K1 and K2 are respectively a sensitivity error coefficient matrix of the triaxial vector sensor and a non-orthogonal error coefficient matrix among three measured axes; and an effective method is utilized to obtain correct zero-offset S0 and a correction coefficient matrix K-1 in the error correction mathematical model, and finally the error correction mathematical model of the measured vector sensor is obtained to carry out calibration compensation on the measuring result of the vector sensor. The method achieves calibration compensation taking into account of all the factors causing the measurement error of the multi-axial sensor, thus improving the accuracy of measuring results; and the method has concise and convenient process and no excessively high requirements on hardware equipment, thus being suitable for various vector sensors.

Description

technical field The invention relates to error correction of a vector sensor, in particular to a calibration compensation method for a three-axis vector sensor and a two-axis vector sensor. Background technique With the advancement of modern science and technology, many industrial fields have higher and higher requirements for measurement accuracy, so simple and accurate instrument calibration technology is very important. For a multi-axis vector sensor (generally refers to a three-axis vector sensor and a two-axis vector sensor), the accuracy of its measurement results is related to the zero offset error, sensitivity error, and The installation error is related; among them, the installation error of each single-axis sensor causes the measurement axis of each single-axis sensor to be non-orthogonal (the angle between the measurement axis of the single-axis sensor and the coordinate axis of the orthogonal coordinate system is generally between tens to several degrees. Betwee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01P21/00G01R35/00

Inventor 张晓明刘俊高丽珍杨玉华陈国彬李永慧崔星

Owner ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com