Accuracy correction for light-curing fast formation

A technology of molding process and calibration method, which is applied in the field of scanner precision calibration of light curing rapid prototyping process, can solve the problems of difficult, difficult and inaccurate distance measurement, and achieve the effect of high calibration accuracy and fast calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

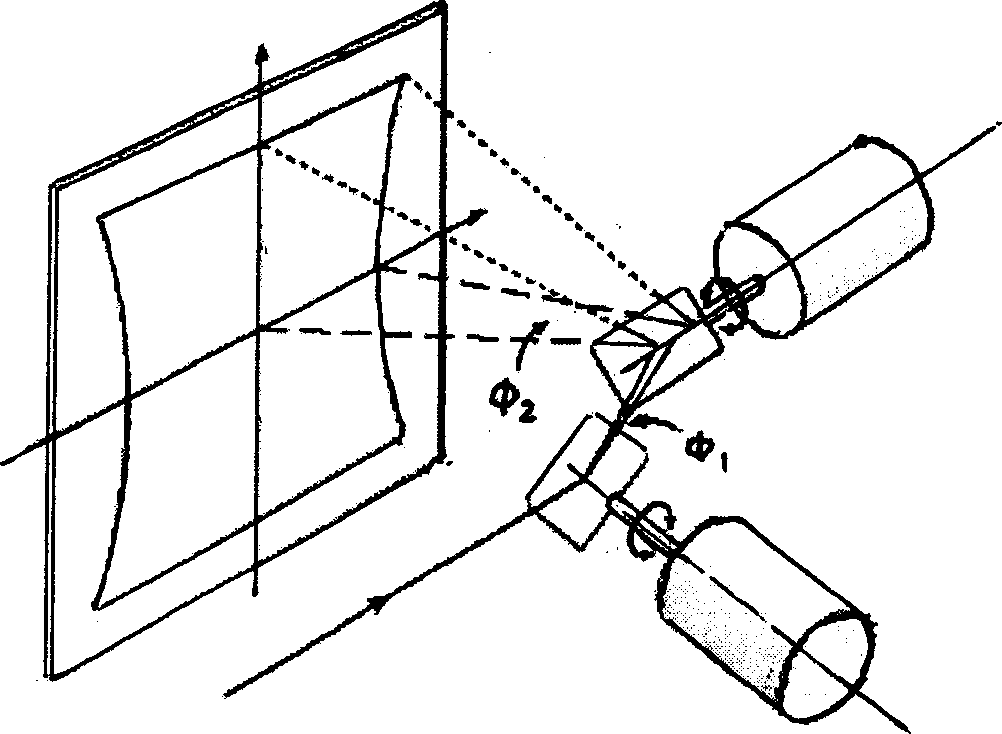

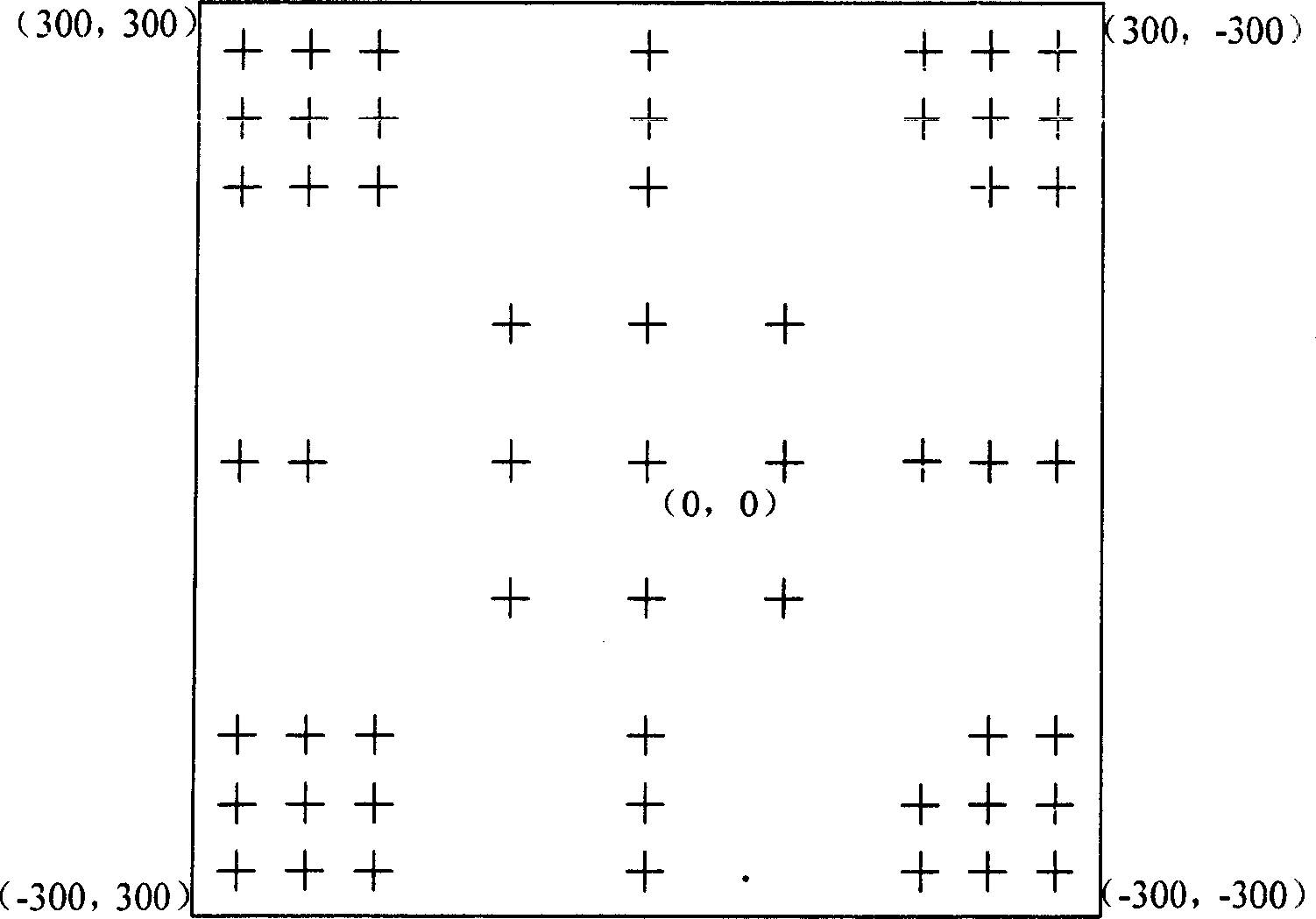

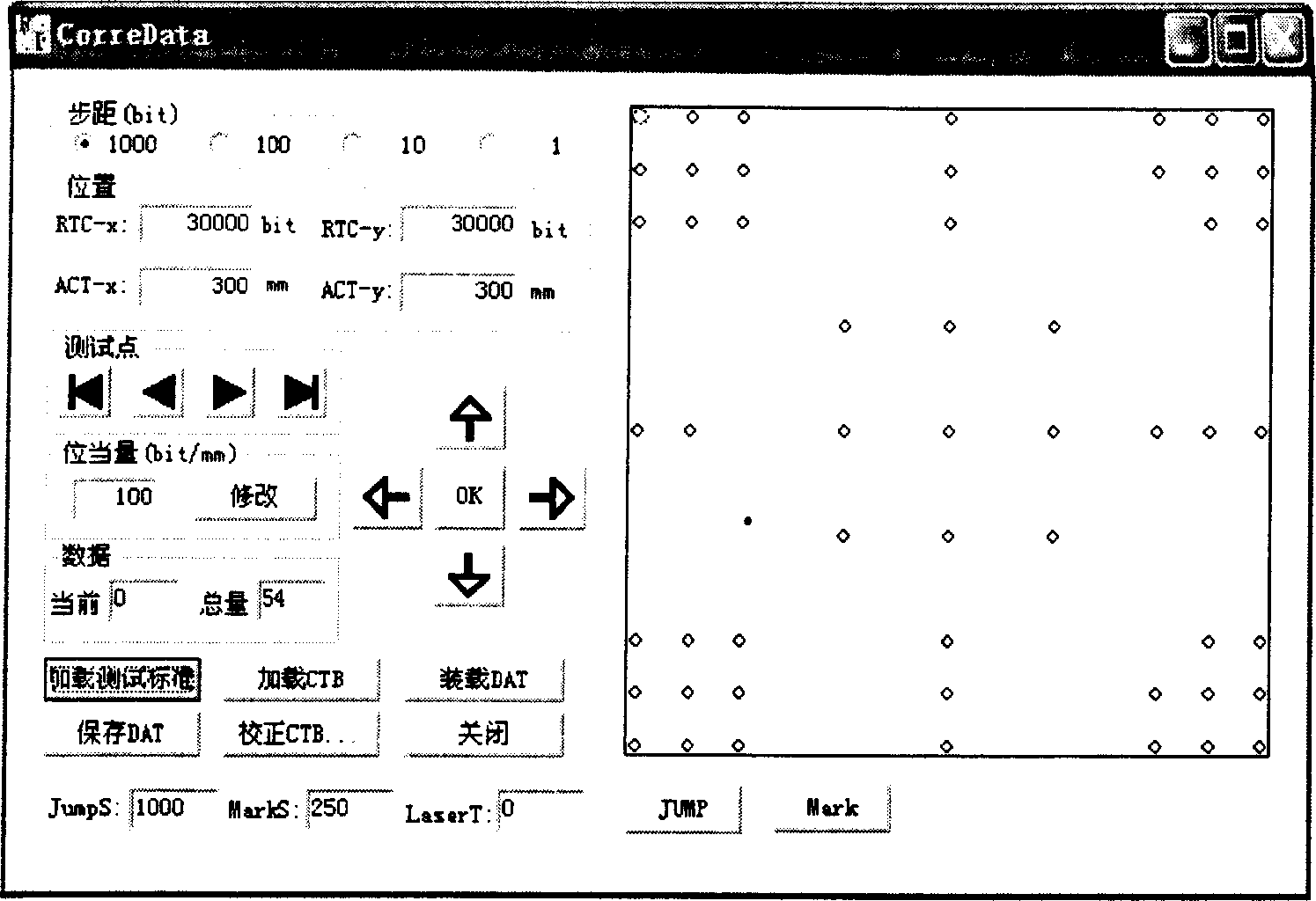

[0017] The basic idea of the accuracy correction method used in the light-curing rapid prototyping process of the present invention is to use a calibration plate, and the calibration points are processed by high-precision numerical control machine tools on the entire surface of the calibration plate. There are 54 scale points for the molding machine, and 33 scale points for the 350×350 light-curing rapid prototyping machine, and the accuracy is guaranteed to be within ±5 μm. Through detection methods such as a level meter, the calibration plate is coincident with the molding plane (resin surface), and the computer controls the scanner of the light-curing rapid prototyping machine to control the laser spot as close as possible to the scale point point by point, and record the correction value of each correction point. Generate an actual calibration file. The scanner can compensate and correct each scanning point according to the new calibration file during operation.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com