Ultralow emission online monitoring system for flue gas pollutants of coal-fired power plants

A technology for monitoring systems and coal-fired power plants, applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of material waste, no system calibration, and increased waste disposal costs, so as to reduce the cost of acid addition and reduce Effect of contact time and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

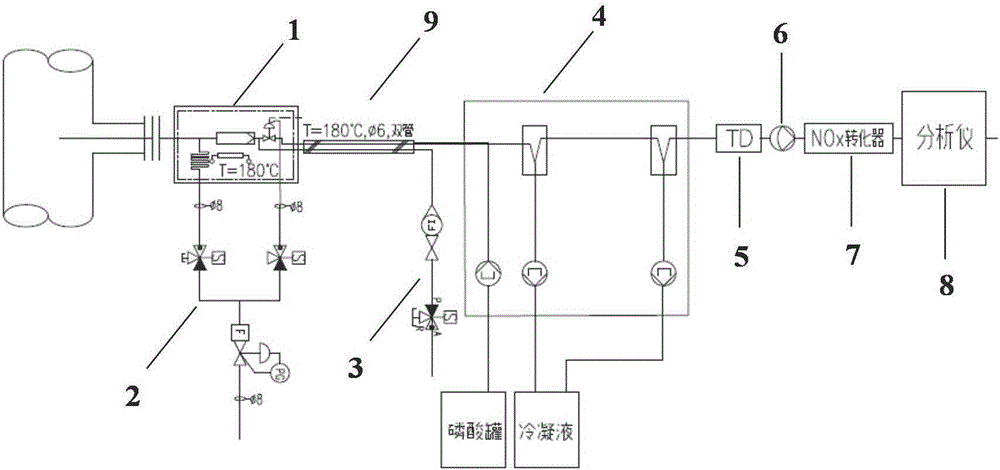

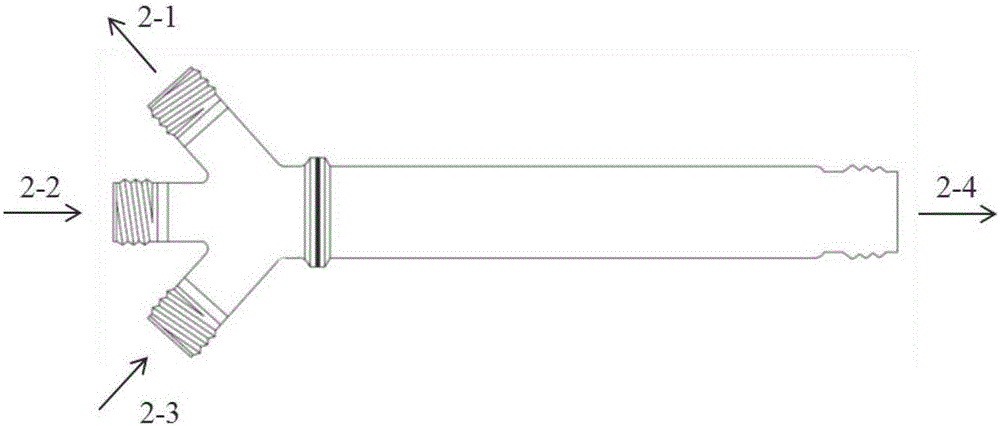

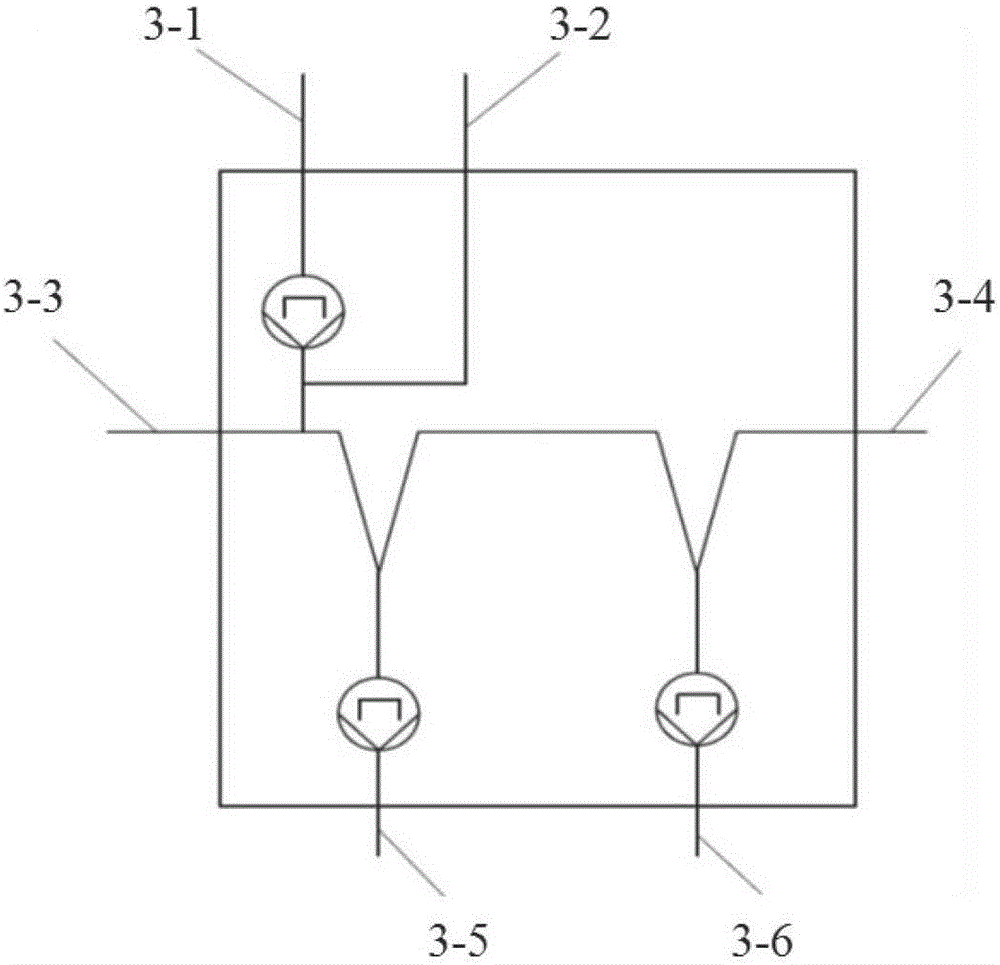

[0032] Embodiment: on-line monitoring system as attached figure 1 As shown, it mainly includes sampling unit 1, back blowing unit 2, double-tube electric heating heating pipeline 9, calibration unit 3, dew point meter 5, air pump 6, NOx converter 7, infrared analyzer 8 and data acquisition, processing and transmission unit , its main innovation is that the monitoring system is equipped with an acid dehumidifier 4 between the calibration unit 3 and the dew point meter 5, which is used to acidify the flue gas entering the acid dehumidifier to prevent the components to be measured in the flue gas from Dissolved in the condensate; the acid-adding dehumidifier 4 has an on-site calibration channel for zero point and span calibration of the analysis device.

[0033] In the embodiment, the sampling unit 1 includes an adjustable heating sheath at 0-250°C, and the heating sheath at 180°C is preferred; the sampling probe rod of 1m-3m can be selected, and the 1.5m long-term stable high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com