Multi-type compatible high-precision ground static testing stand for rocket engine

A rocket engine and static test technology, which is applied in jet engine testing, gas turbine engine testing, etc., can solve problems that cannot be used to detect solid rocket motors, reduce detection accuracy, increase test risks, etc., and achieve reliable data, safe operation, The effect of guaranteeing detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

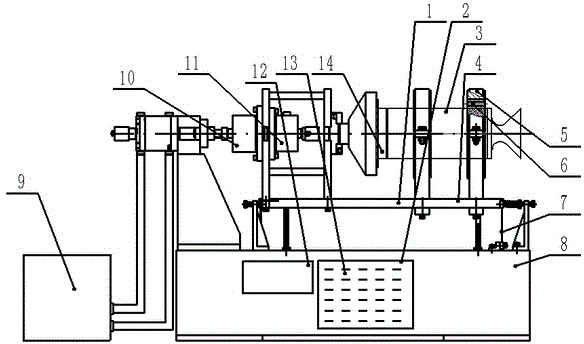

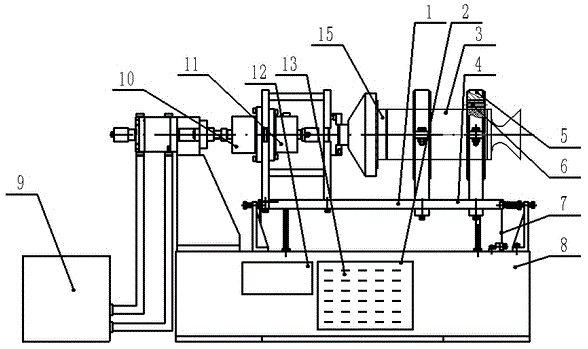

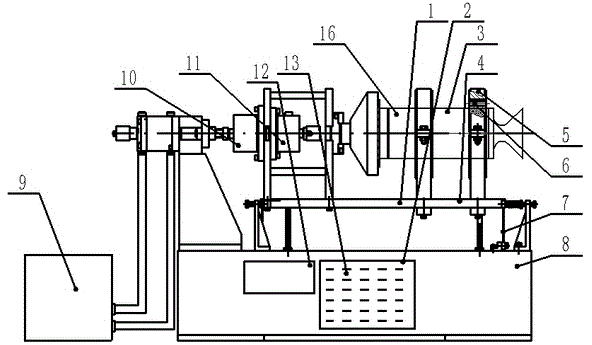

[0012] The embodiments provided below by the accompanying drawings are divided into four parts to further illustrate the present invention.

[0013] The first part, structure composition.

[0014] The embodiment includes: a bench system (1), an in-situ calibration system (2), and a solid rocket motor sample (3).

[0015] Bench system (1) includes: moving frame (4), counterweight snap ring (5), counterweight module (6), leaf spring (7), base (8)

[0016] The in-situ calibration system (2) includes: a hydraulic press (9), a standard thrust sensor (10), a working thrust sensor (11), a standard calibration value table (12), and an accurate digital table (13).

[0017] The solid rocket motor samples (3) include: a test sample one (14), a test sample two (15), and a test sample three (16).

[0018] The second part is the detection test process of the tested sample one (14). Tested sample one (14) is a standard φ260 solid rocket motor. The tested sample one (14) is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com