Method and system for evaluating explosion risk of chemical device by utilizing computer

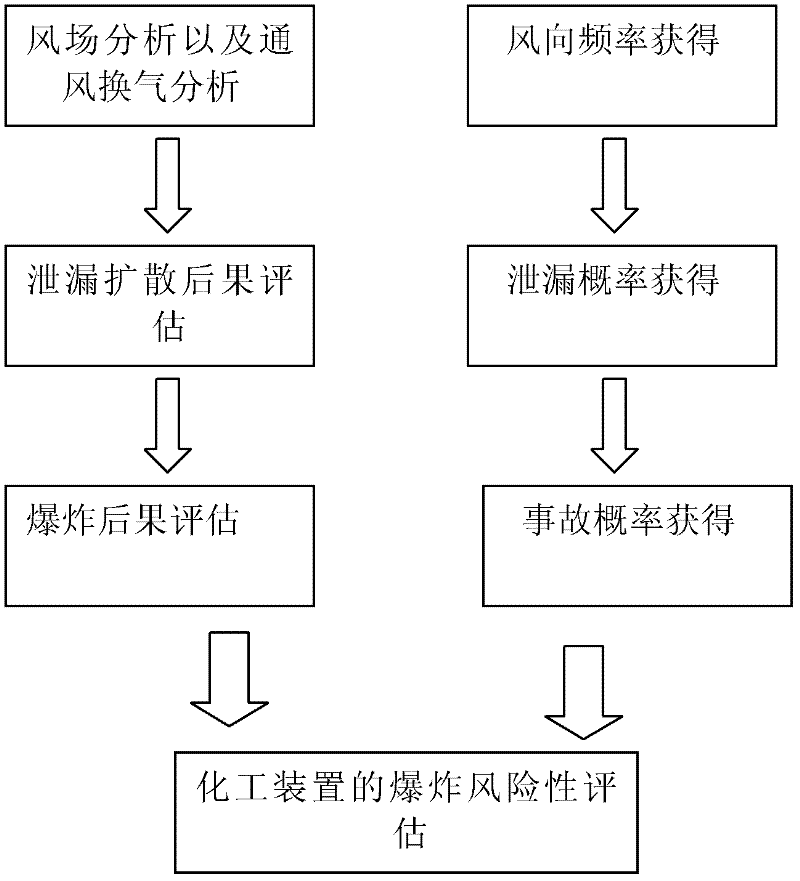

A risk assessment and computer technology, applied in the field of risk assessment, can solve problems such as insufficient accuracy and expressiveness, inability to predict near-field explosions, and intuition, and achieve reasonable and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Taking the evaluation of a certain coal gasification unit as an example

[0129] first step

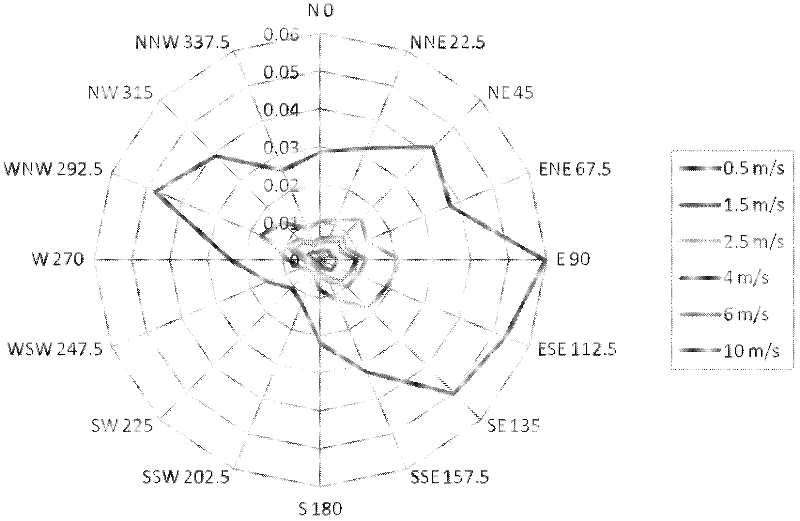

[0130] A three-dimensional model of the chemical plant was constructed using a three-dimensional laser scanner combined with three-dimensional modeling software MICROSTATION; the local wind speed and direction probability and dominant wind direction obtained according to meteorological conditions are shown in Table 1.

[0131] Table 1

[0132]

[0133] Table 1 continued

[0134]

[0135] Draw the wind field according to Table 1 figure 2 , to get the dominant wind direction.

[0136] According to the dominant wind direction as the axis, the above wind speed and direction frequencies are reclassified, as shown in Table 2.

[0137] Table 2

[0138]

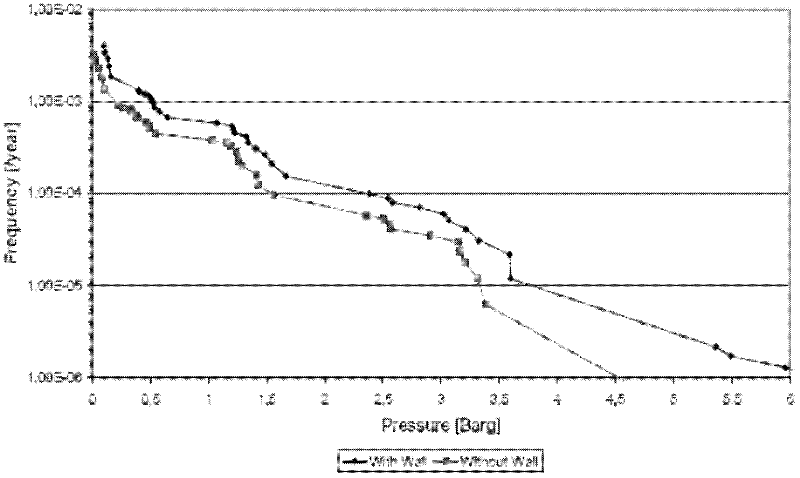

[0139] By classifying the wind field data of the wind field analysis, according to different wind field levels, select and calculate the wind speed and select different leakage points, leakage volume, leakage direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com