Reliability Assessment Method for Multi-parameter Correlated Degraded Products Considering Multi-source Uncertainty

An uncertain, multi-parameter technology, applied in the field of reliability evaluation of multi-parameter related degraded products considering multi-source uncertainty, can solve the problems of lack of rationality and accuracy of reliability evaluation results, and achieve a concise evaluation process, Improved accuracy and applicability, accurate and reasonable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

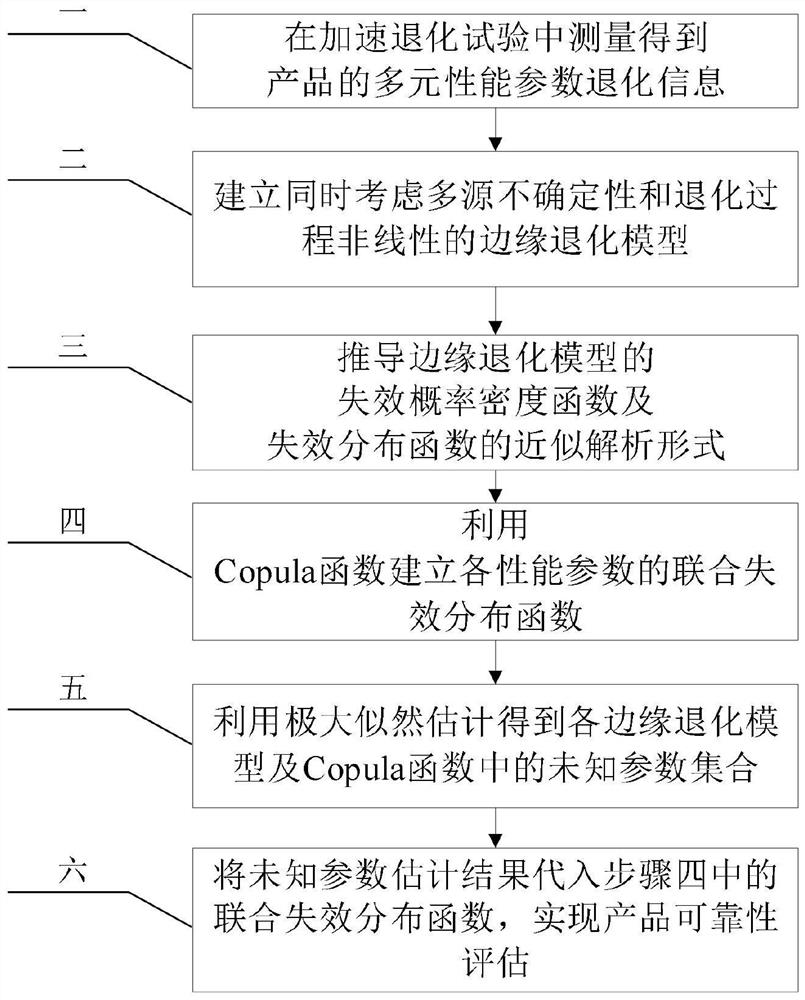

[0022] Specific Embodiment 1: This embodiment provides a method for evaluating the reliability of multi-parameter related degradation products considering multi-source uncertainties. The method first designs a reasonable accelerated degradation test by analyzing the task profile and failure mechanism of the product, And measure the multivariate performance parameters of the product; then, for the degradation data of a single performance parameter, establish and consider multi-source uncertainties (randomness of the degradation process, differences between sample individuals, and measurement errors) and non-linearity of the degradation process. Linear edge degradation model, and in the case of a given failure threshold, with the help of the concept of first arrival time (the time when the performance degradation reaches the failure threshold for the first time), approximate analytical forms of failure probability density function and failure distribution function are derived; the...

specific Embodiment approach 2

[0047] Specific implementation mode two: the following combination Figure 1 to Figure 5 Describe this embodiment. This embodiment is a further description of the specific embodiment 1. In this embodiment, a certain type of film capacitor is used as an object to evaluate the reliability of multi-parameter correlation degradation considering multi-source uncertainties. The specific steps are as follows:

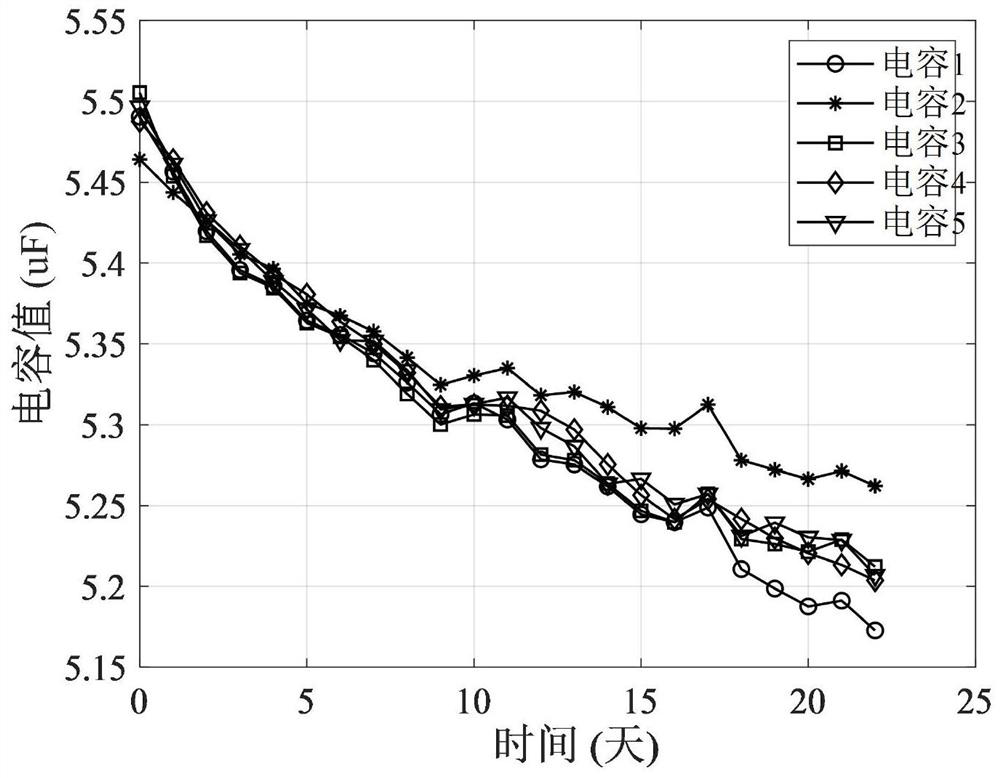

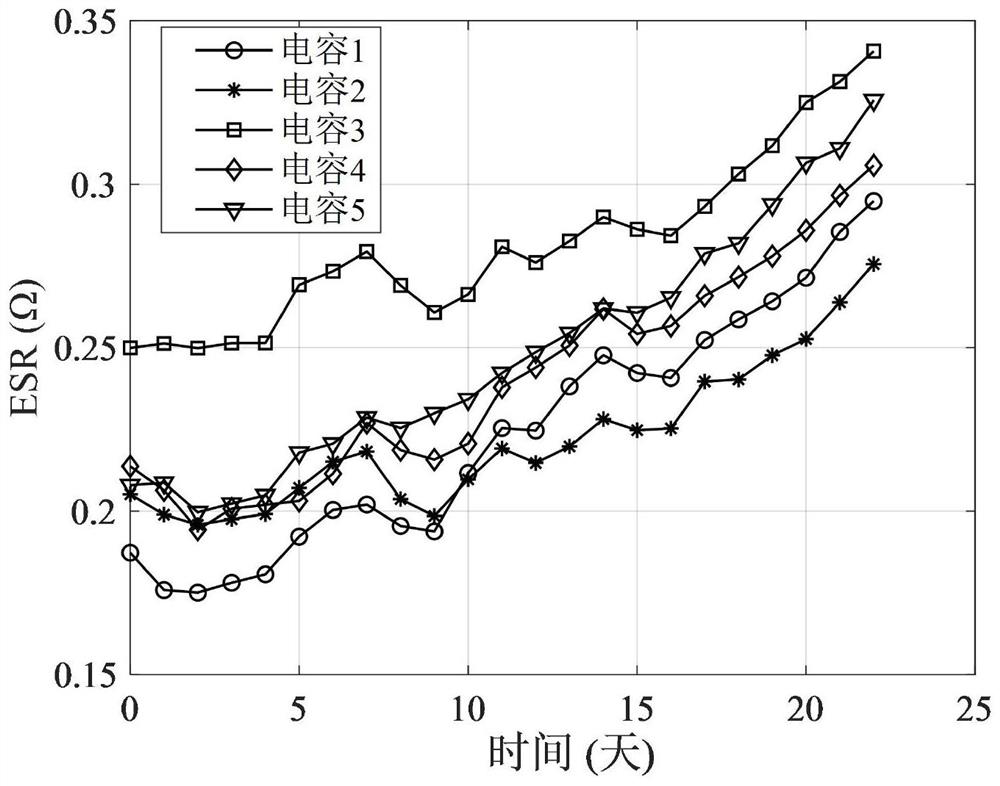

[0048] Step 1: By analyzing the task profile and failure mechanism of a certain type of film capacitor, using voltage and temperature as the accelerated stress, put 5 samples into the accelerated degradation test, and continuously measure the capacitance and equivalent series resistance of the 5 film capacitors ( ESR), the degradation trajectories of the two performance parameters are as follows figure 2 and image 3 shown;

[0049] Step 2: For the capacitance value and ESR, respectively establish an edge degradation model Y that considers multi-source uncertainty (randomne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com