Dry testing method for pressure limiting valve opening pressure

A test method and cracking pressure technology, which is applied in the dry test of the cracking pressure of the pressure limiting valve of the oil pump and the detection field of the pressure limiting valve of the oil pump. Advanced problems, to achieve the effect of short test period, low cost and good operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

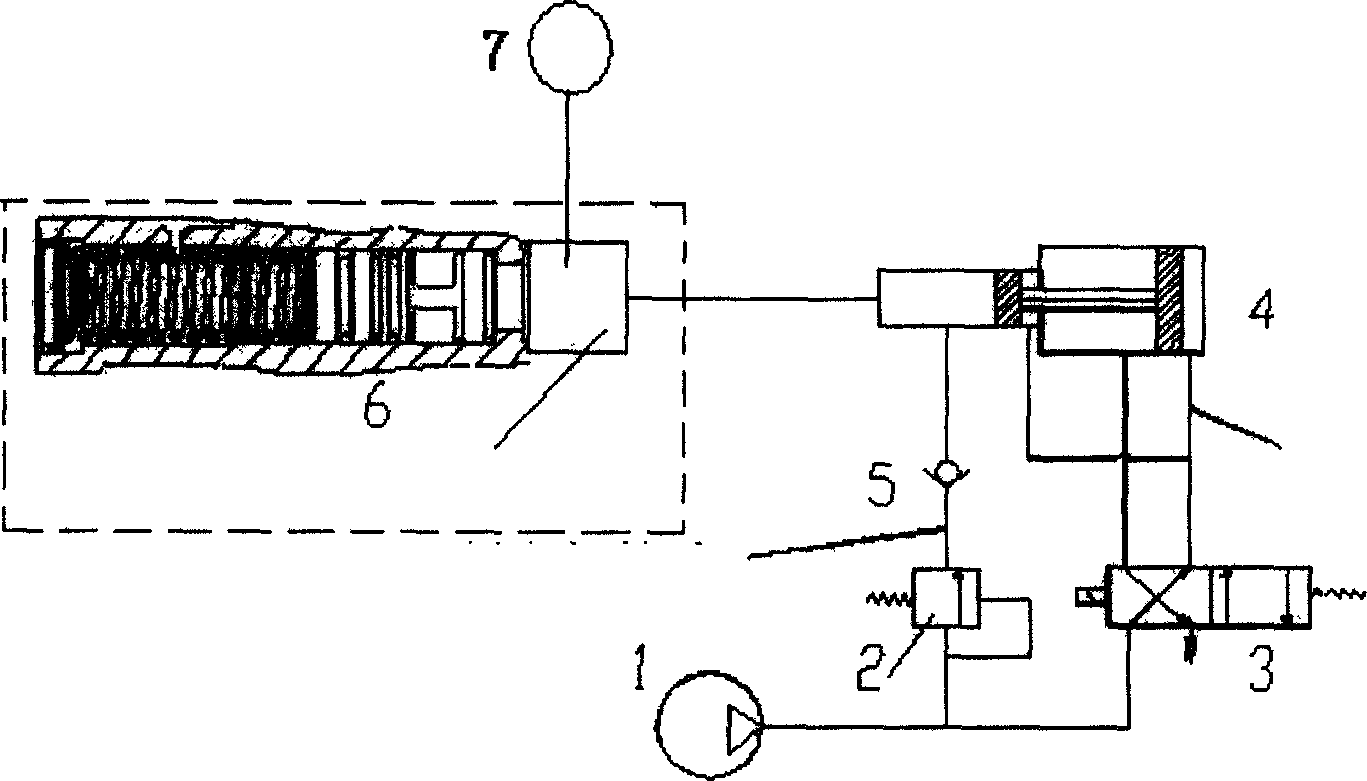

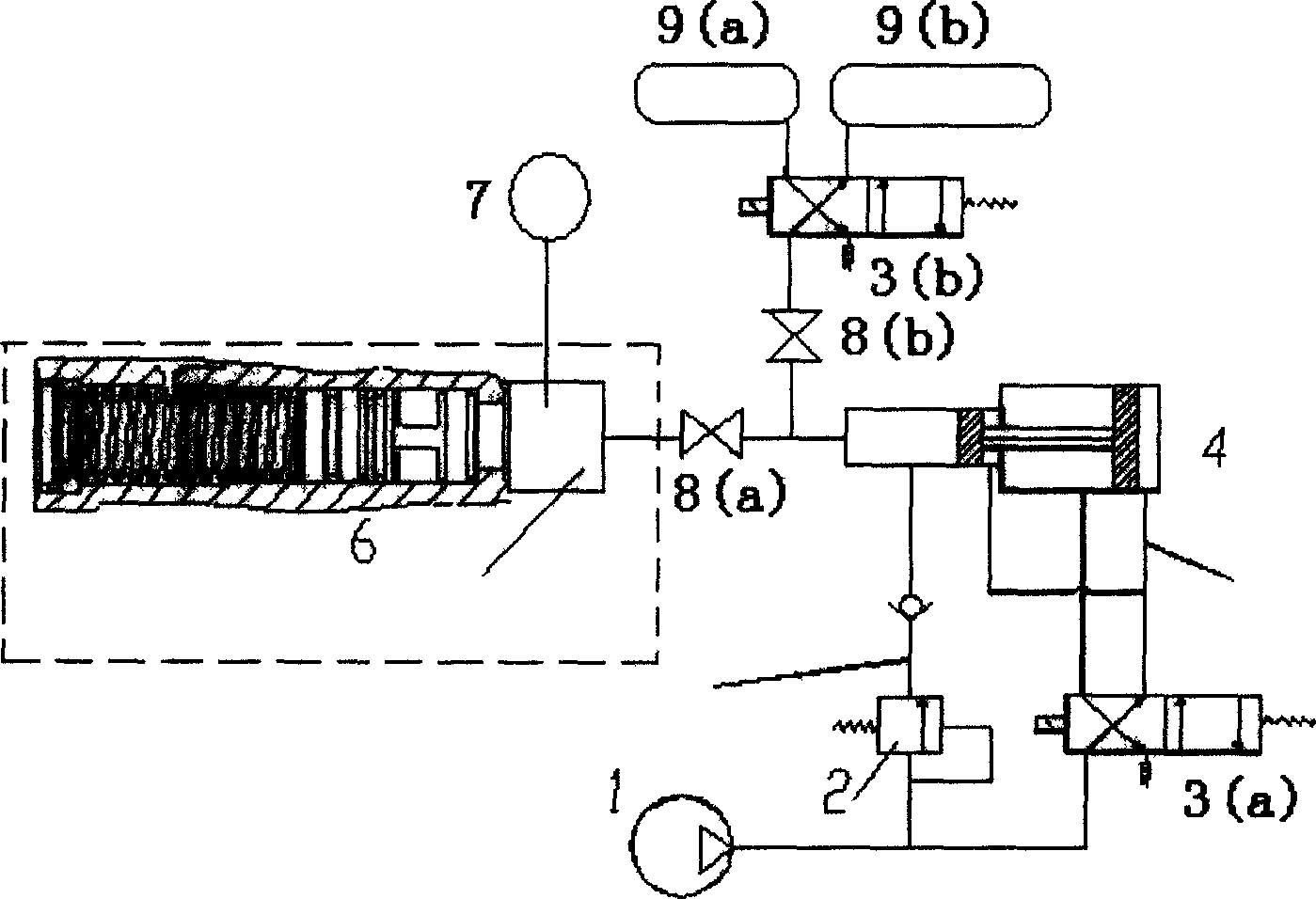

[0010] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 and figure 2 The dry test method for opening pressure of the pressure limiting valve shown is characterized in that: the test device includes an air source 1; and a pre-inflated pipeline, a pressurized pipeline, and a body cavity pipeline of a one-way valve of the tested test product, and a pre-inflated tube The pressure regulating valve 2 is connected in series with the one-way valve 5; the booster pipeline is connected in series by the electromagnetic reversing valve 3 and the booster mechanism 4, and the pressure regulating valve 2 and the electromagnetic reversing valve 3 at the input end of the two pipelines are connected with the air source 1 Connected in parallel, the output end check valve 5 and booster mechanism 4 are connected in parallel with the cavity of the tested test product, and the input end of the pressure sensor is connected to the cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com