Mouse cage type V-shaped straight wire sieve tube

A squirrel-cage, straight wire technology, applied in the direction of drilling pipe, casing, production fluid, etc., to avoid sharp changes, reduce the probability of collision, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

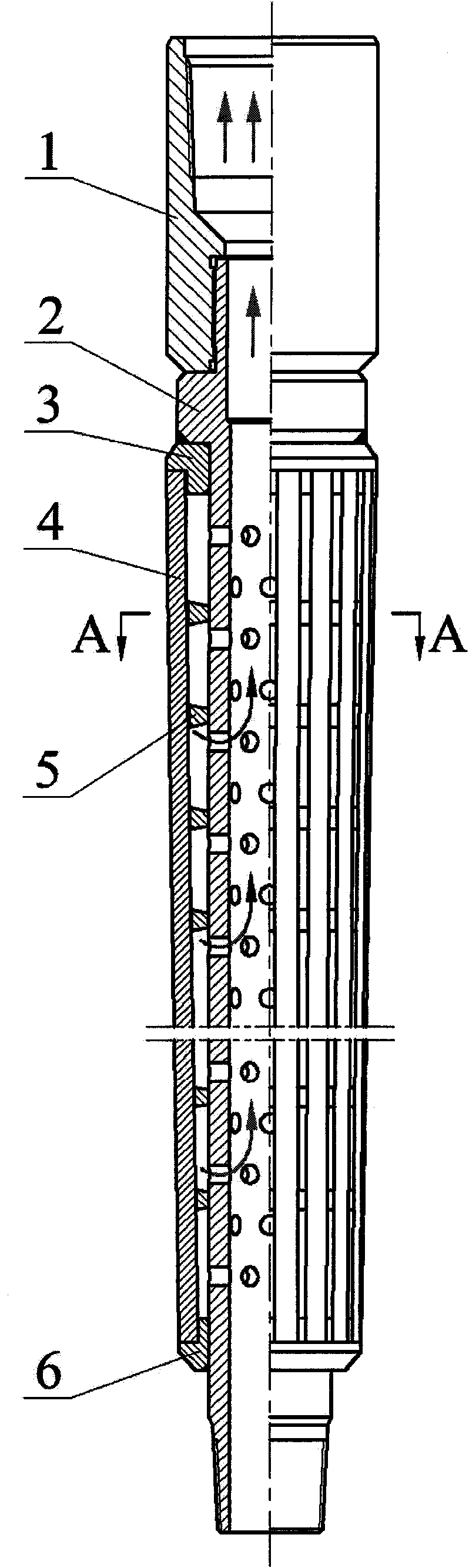

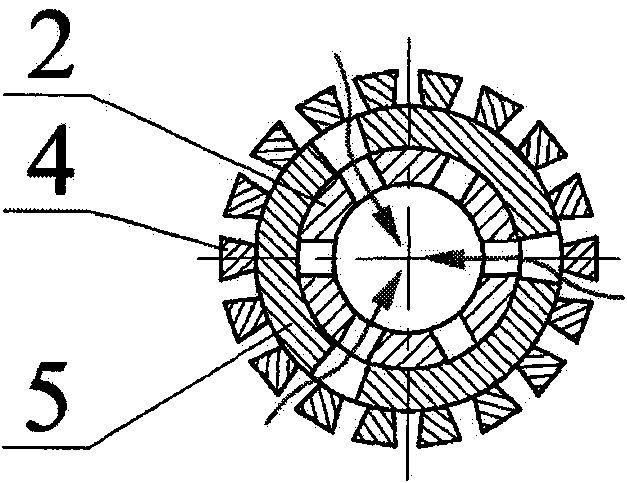

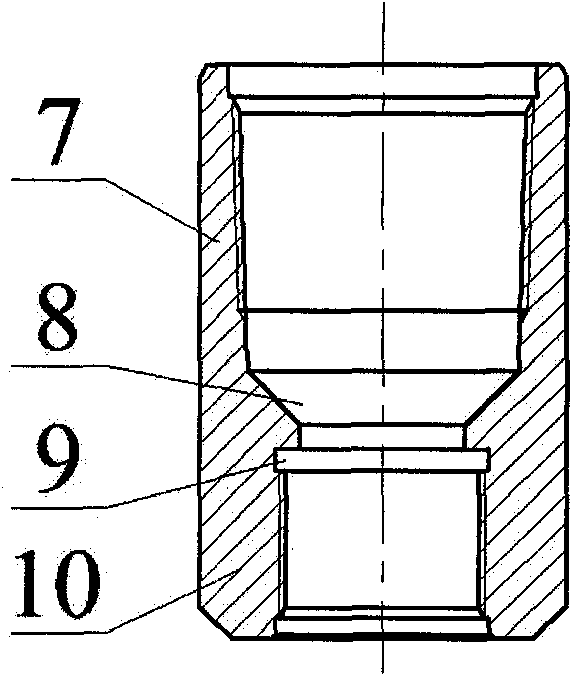

[0017] exist figure 1Among them, the squirrel-cage V-shaped straight-wire screen is, from top to bottom, screen collar 1, base 2, upper hoop 3, straight wire screen sleeve 4, ring rib 5 and lower hoop 6. Before assembly, each component should be deburred and cleaned. Check whether each coating and spray welding layer is firmly bonded to the base metal, and whether there are defects such as bubbles, pitting, peeling and bruising on the surface. During assembly, each ordinary thread is coated with anaerobic adhesive when it is finally tightened. After welding the ring rib 5, the straight wire screen tube sleeve 4, the upper hoop 3 and the lower hoop 6 into one body in sequence, start from the lower end of the base 2 along the The upper end surface of the shoulder of the upper hoop 3 and the lower end surface of the shoulder of the base body 2 are welded together by a fillet weld, and the lower hoop 6 is welded together with the base pipe of the base body 2 by circumferential wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com