Helical spring and suspension gear

A coil spring and helical technology, used in elastic suspensions, suspensions, springs/shock absorbers, etc., can solve the problems of large buckling displacement, cannot be manufactured at low cost, and cannot be applied to occasions with limited installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments applicable to the present invention will be described in detail below with reference to the accompanying drawings.

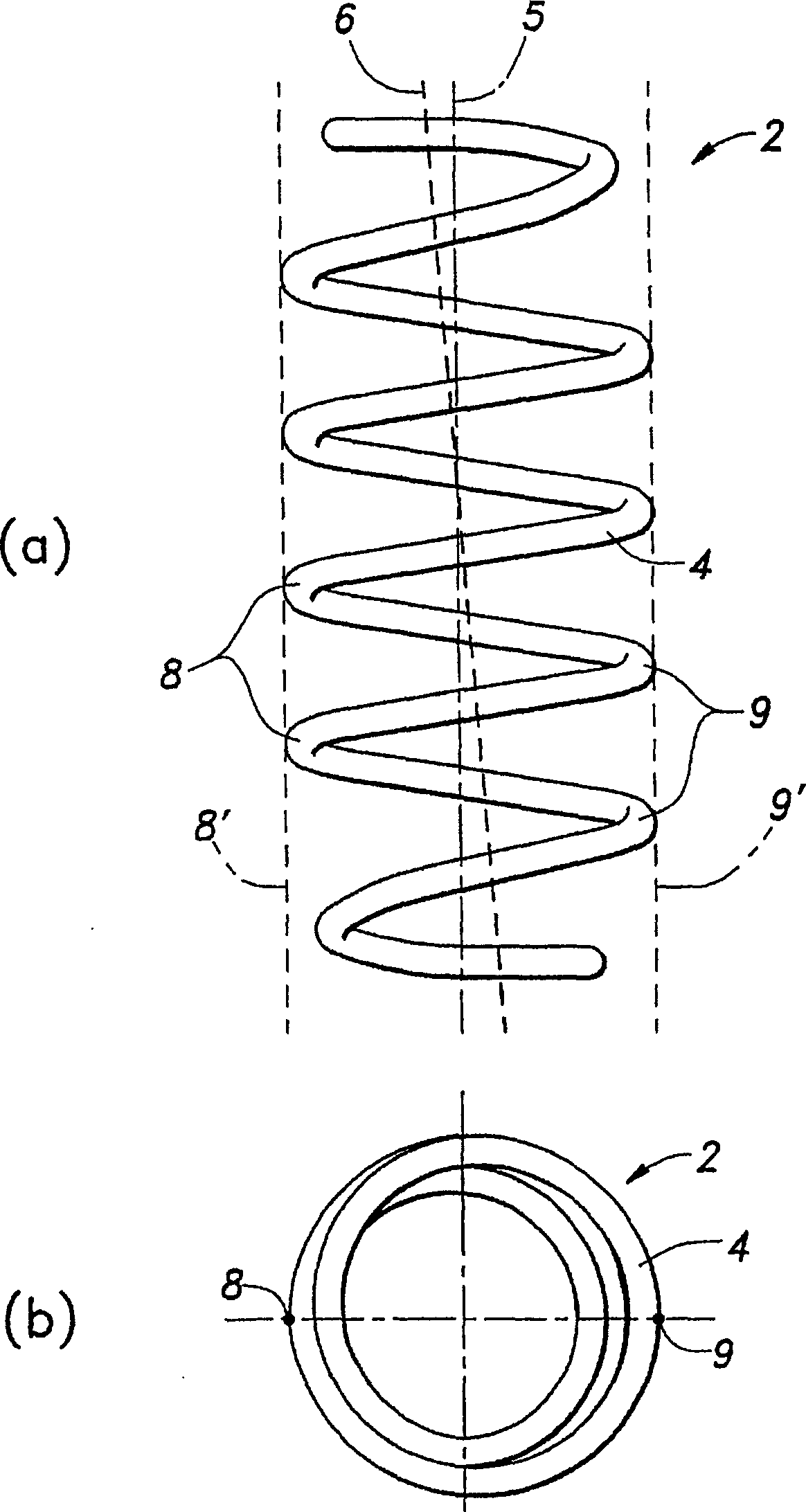

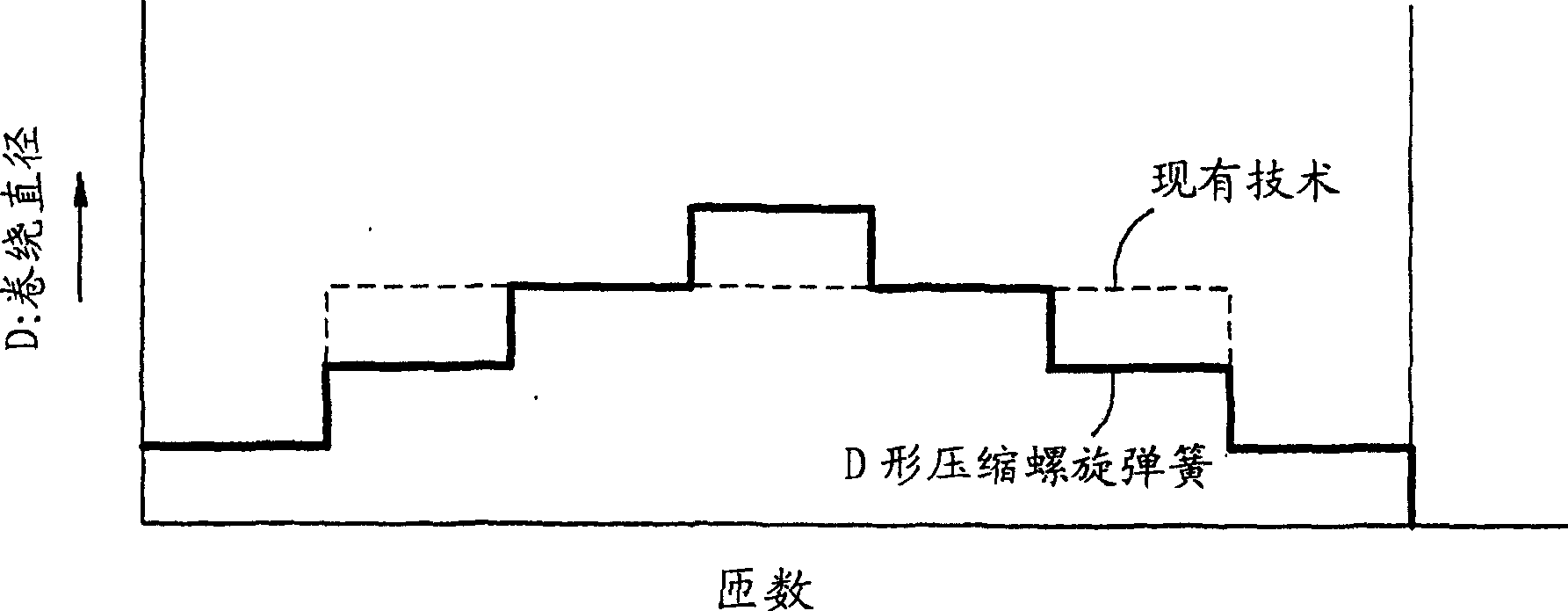

[0039] figure 2 a and figure 2 b represents a compression coil spring 2 with a mounting ring portion in the form of the prior art. In general, a compression coil spring is formed by winding a helical wire 4 around a central axis 5 . Due to the limited number of turns, it cannot be completely symmetrical around the central axis 5 , so the load axis 6 is slightly inclined relative to the central axis 5 . The load axis 6 can be regarded as the direction of the reaction force generated on the spring 2 when a load is applied in the direction of the central axis 5 .

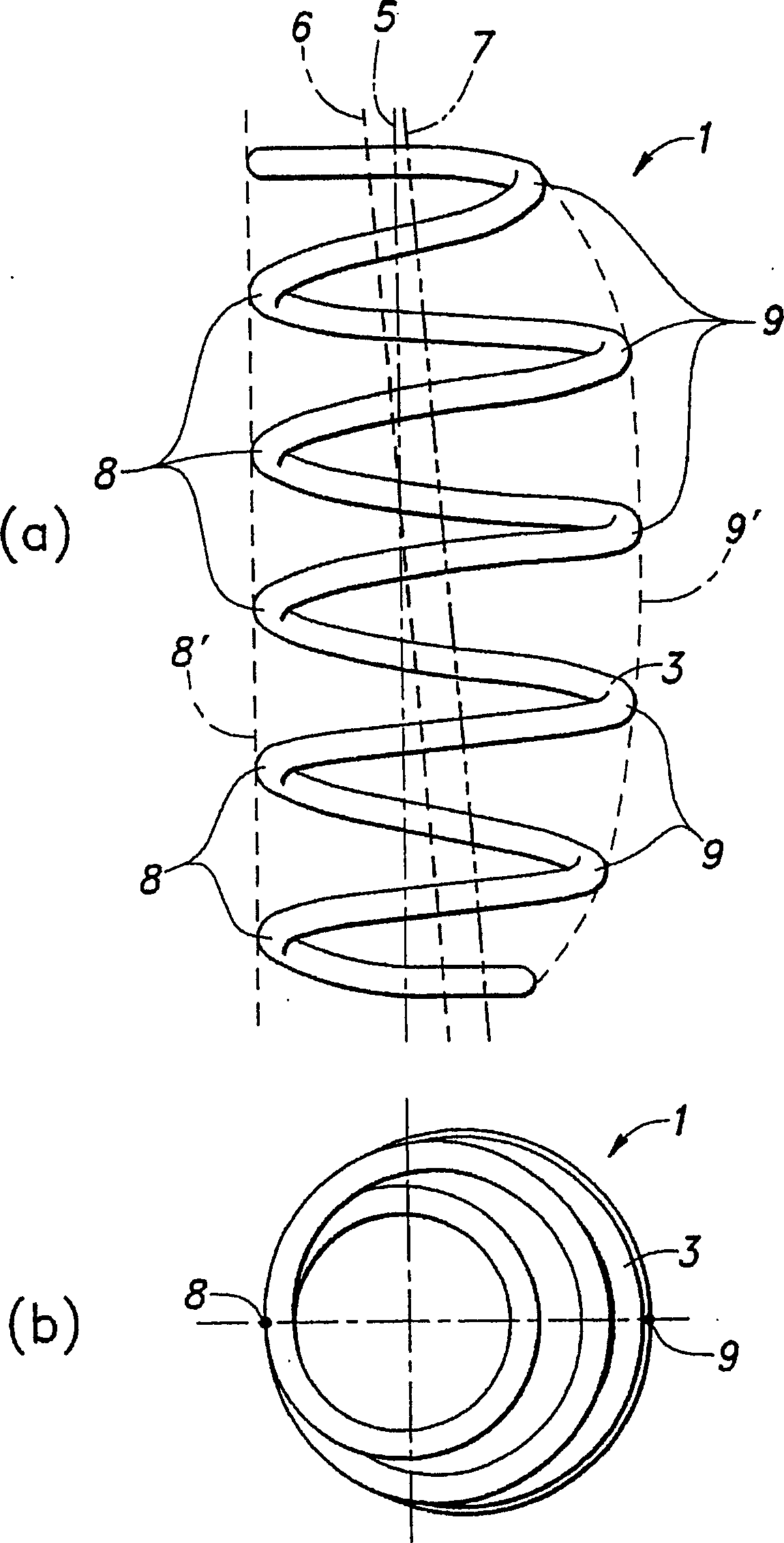

[0040] figure 1 a and figure 1 b represents the D-shaped compression coil spring 1 based on the present invention. One side position 8 is used as the reference position for changing the winding diameter, and the straight line 8' connecting one side position 8 is roughly parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com