Device for clean utilization and mercury recovery of high-mercury coal and method

A coal and clean technology, applied in the field of coal chemical industry, can solve problems such as mercury pollution, achieve the effects of reducing mercury pollution, increasing efficiency, and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

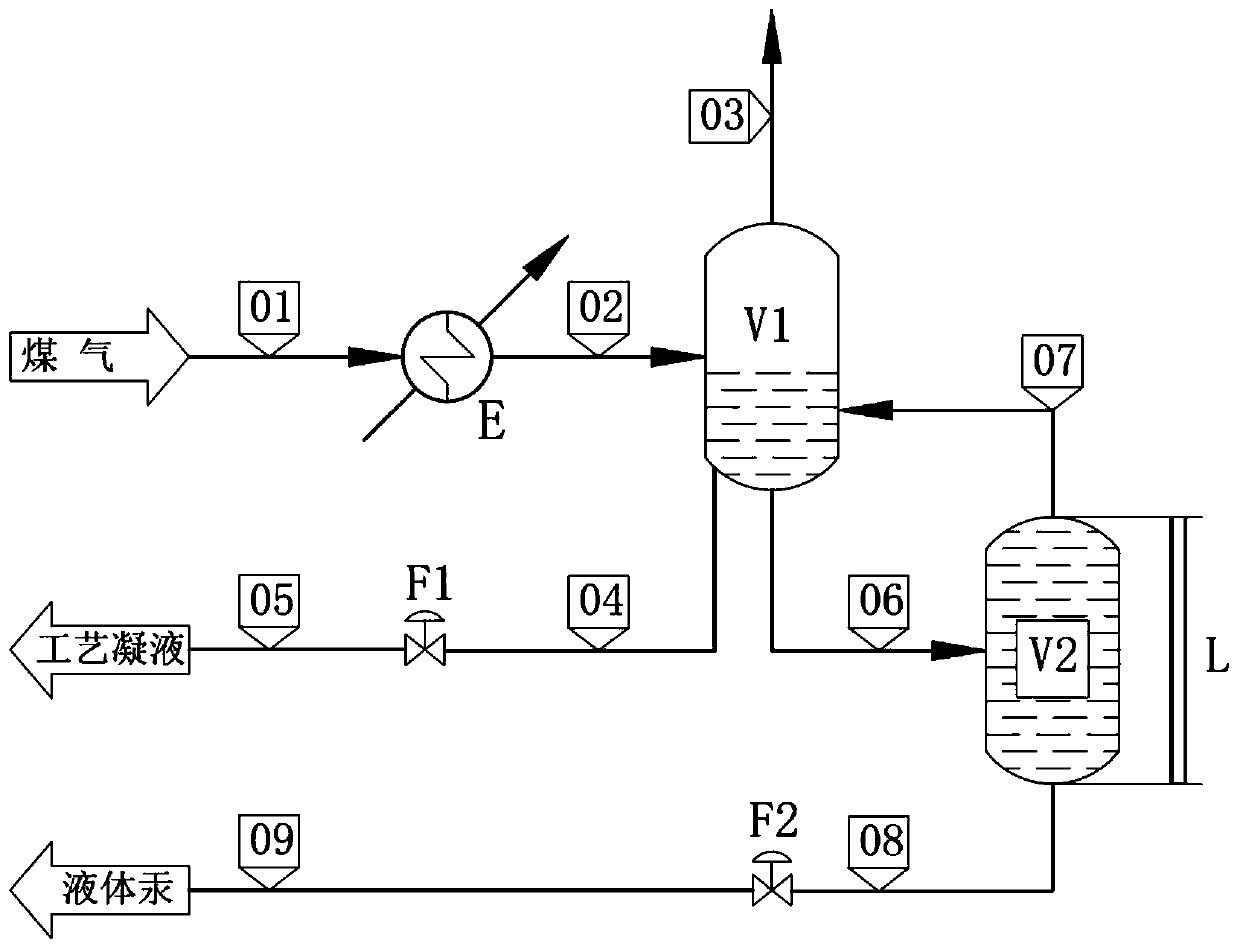

[0035] 60 tons of raw coal with a mercury content of 45mg / kg, the gas output after pulverized coal gasification: 3.5Mpa, 215°C, 233068NM 3 / h water gas, water 121322kg / h, mercury 2.7kg / h.

[0036] Coal gas (01) is cooled down to 40°C by heat exchanger E, and enters the gas-liquid separation tank V1 for separation, and the separated liquid is 121169.38kg / h, of which liquid water is 121166.72kg / h, and liquid mercury is 2.65816kg / h; gas-liquid separation tank V1 Top output process gas 81836.26NM 3 / h, which contains 0.041775kg / h of mercury.

[0037] The liquid mercury is separated and settled by the gas-liquid separation tank V1, and deposited and recovered by the metal collection and separation tank V2. It can separate and recover 2.658kg / h of raw coal, and the mercury recovery rate is 98.45%.

[0038] During the process, mercury metal can be separated and recovered, and 21265.26 kg of mercury metal can be recovered in 8000 hours of annual production, which increases benefits ...

Embodiment 2

[0040] 60 tons of raw coal with a mercury content of 45mg / Kg, the gas output after coal-water slurry gasification: 6.0Mpa, 230°C, 173483NM3 / h water gas, of which water 73430.28kg / h, mercury 2.7kg / h.

[0041]Coal gas (01) is cooled down to 40°C by heat exchanger E, and enters the gas-liquid separation tank V1 for separation, and the separated liquid is 74166kg / h, of which liquid water is 73335kg / h, and liquid mercury is 2.67688kg / h; the top output of the gas-liquid separation tank V1 Process gas 81784.9NM 3 / h, which contains 0.02306kg / h of mercury.

[0042] The liquid mercury is separated and settled by the gas-liquid separation tank V1, and deposited and recovered by the metal collection and separation tank V2. It can separate and recover 2.658kg / h of raw coal, and the mercury recovery rate is 99.14%.

[0043] During the process, mercury metal can be separated and recycled, and 21,415 kg of mercury metal can be recovered in 8,000 hours of annual production, which increases b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com