Energy-saving control method and system for revolving speed of engine

A technology for engine speed and energy-saving control, applied in engine control, machine/engine, governor, etc., to solve problems affecting system working stability and driving comfort, changes in driving speed requirements, and inability to take into account driving conditions. , to avoid frequent and large changes, improve driving comfort, and improve the time of the economic zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

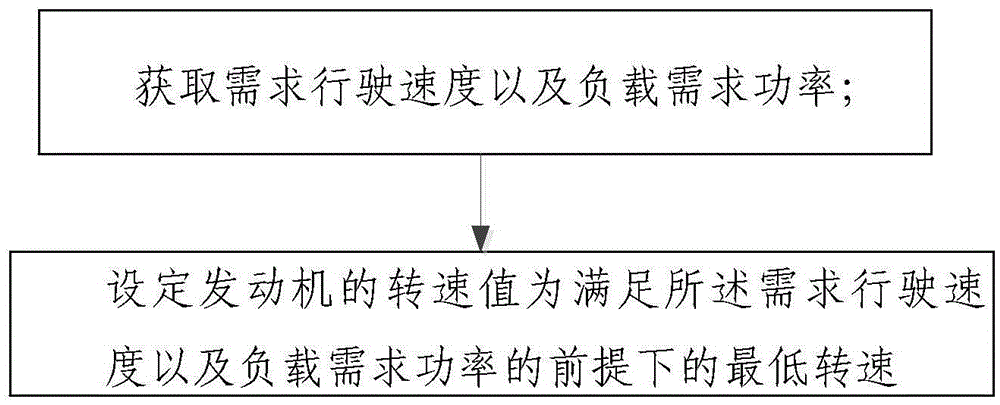

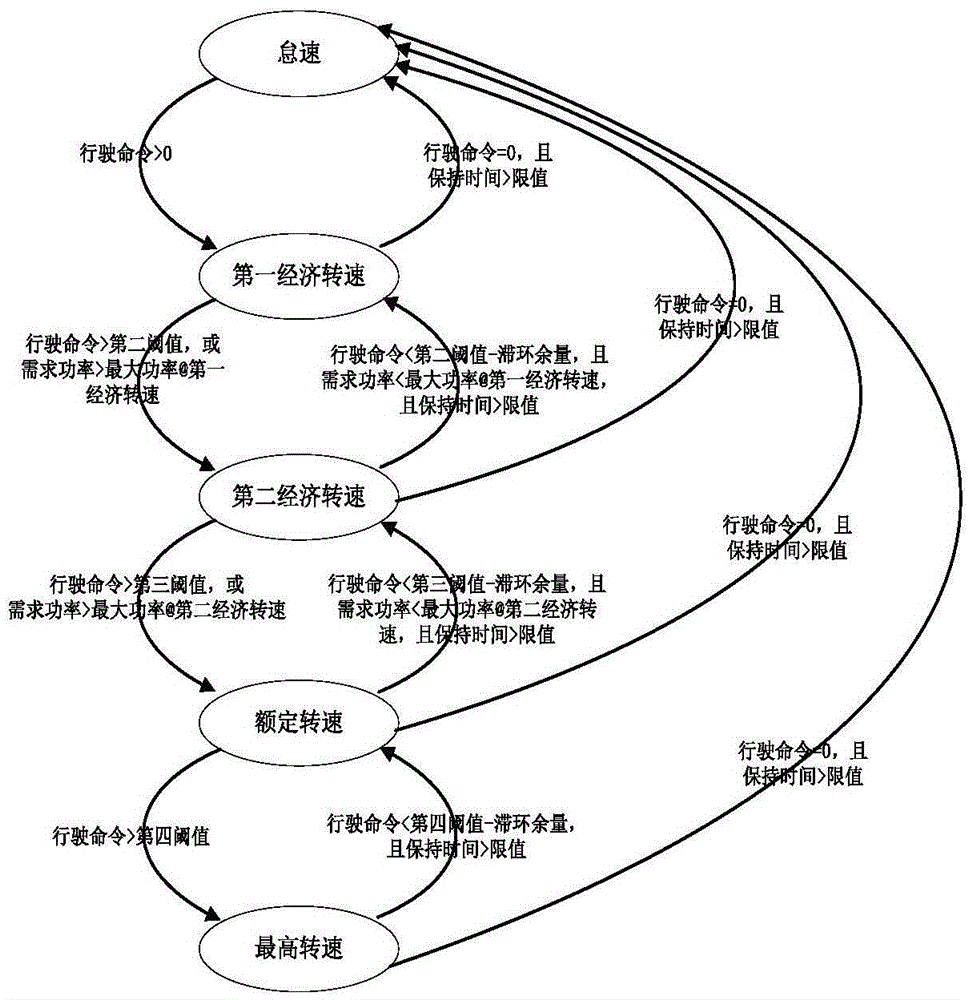

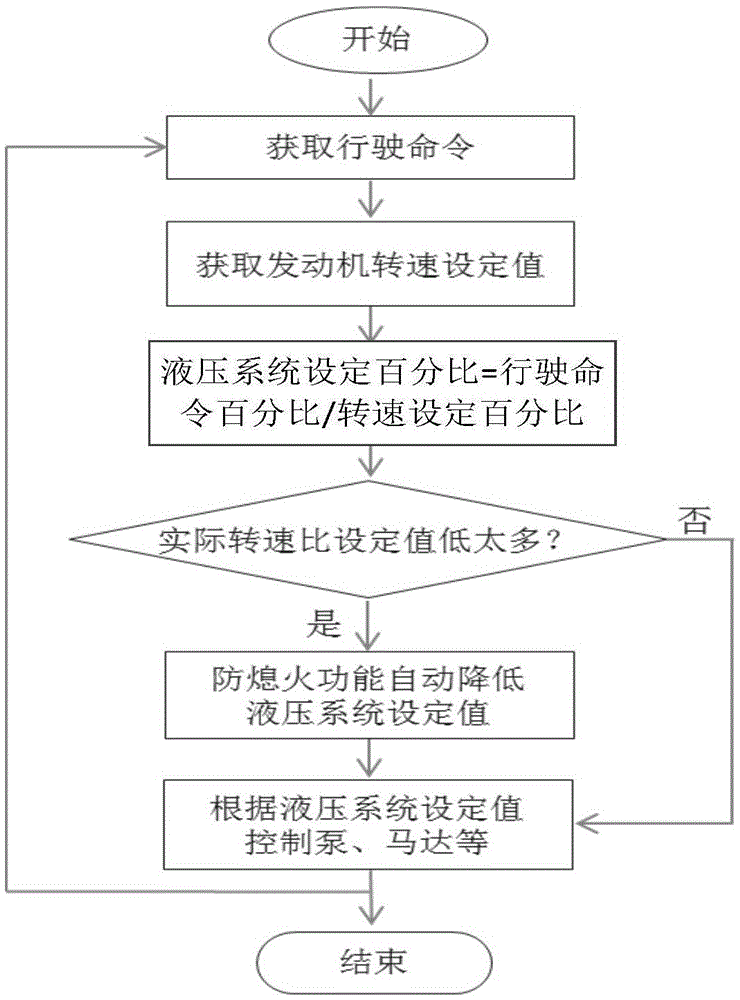

[0052] Such as figure 1As shown, the present invention provides an energy-saving control method for engine speed, including: obtaining the required driving speed and load required power; .

[0053] The basic characteristic of the engine is that the external characteristic torque of the engine is the largest at a certain speed value in the middle speed zone. At the same time, in the middle speed range, which is also the region with the best engine efficiency characteristics, the fuel required to output the same power in this speed range is the least. As the speed increases until the rated speed, although the external characteristic torque of the engine is decreasing, the output power of the engine is gradually increasing, and the economy is gradually getting worse. From the rated speed to the maximum speed, the external characteristic torque of the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com