Aluminum piece automatic rolling device for camellia grafting

A technology of camellia grafting and aluminum flakes, which is applied in grafting and other directions, can solve the problems that aluminum flakes are easy to cut and hurt people, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of ensuring stability and continuity, avoiding trouble and labor, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

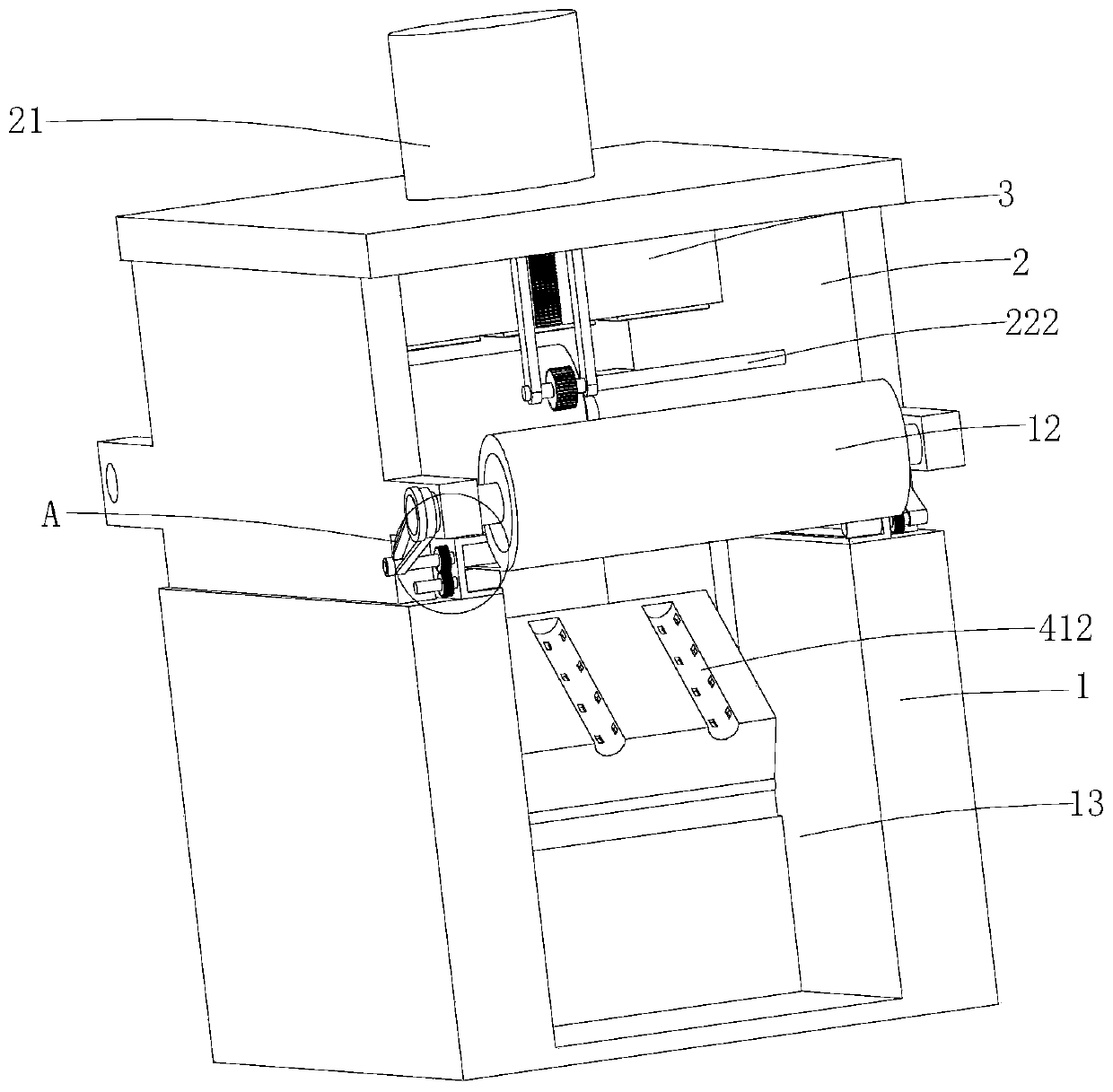

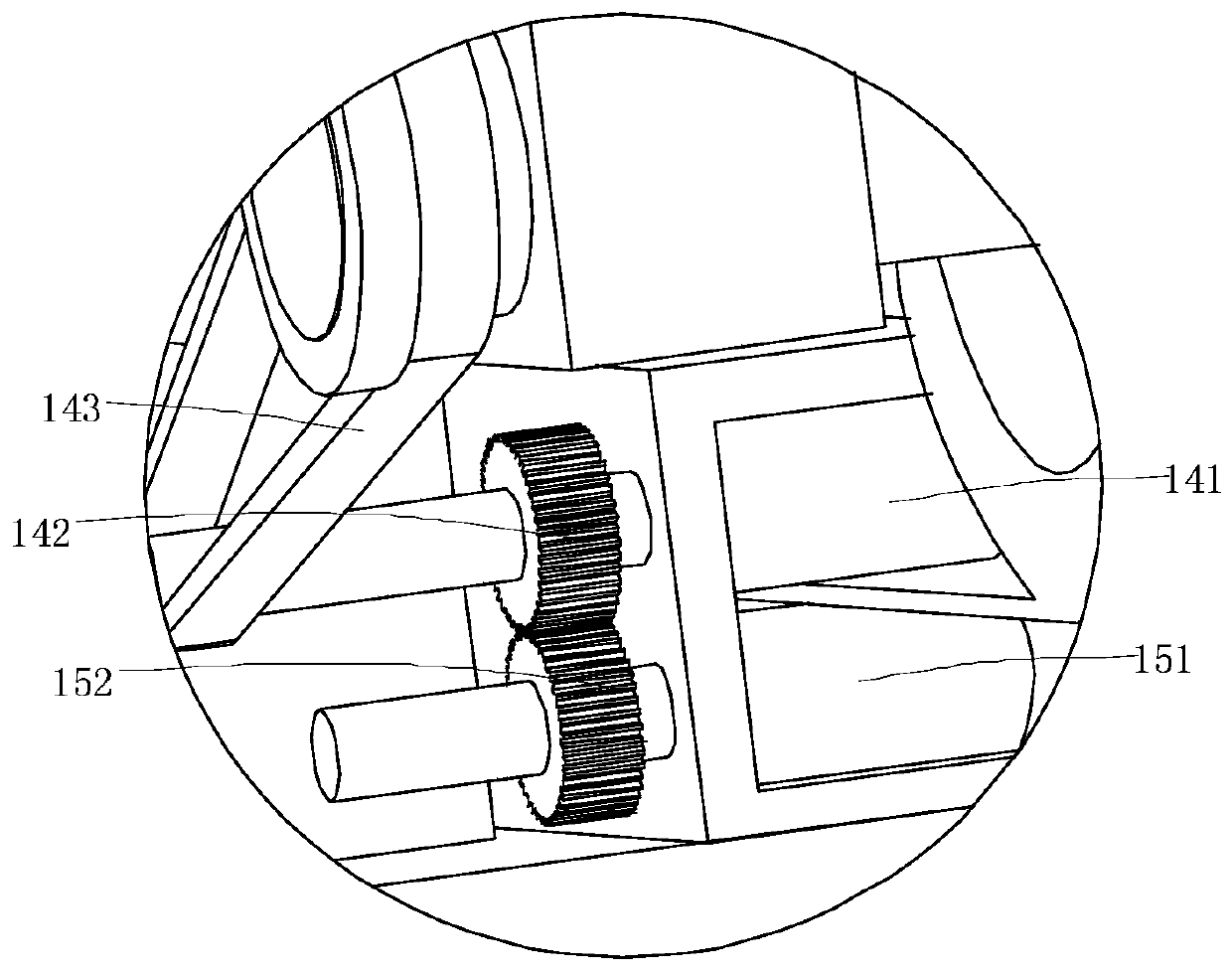

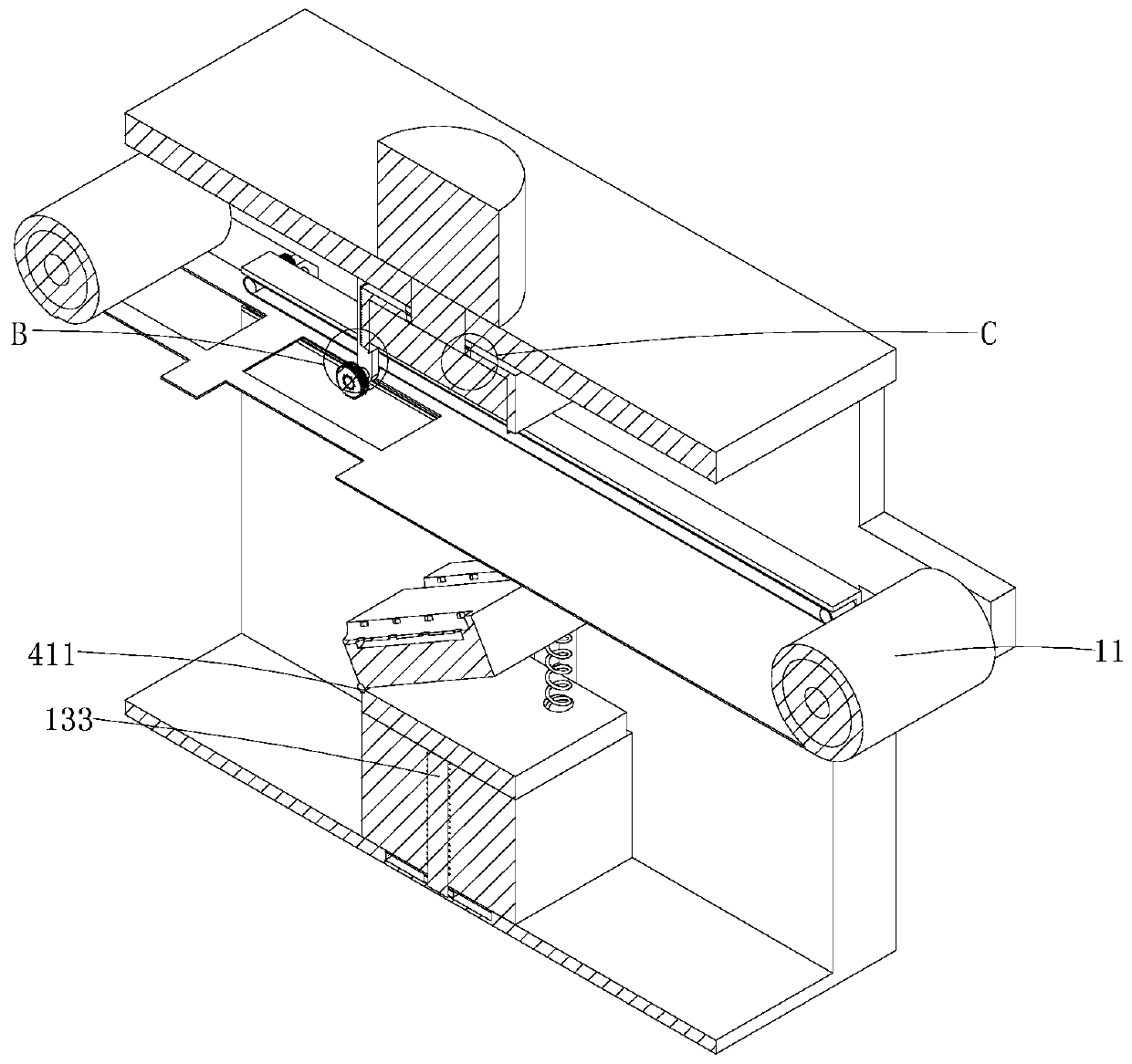

[0029] like Figure 1-13Shown, a kind of aluminum sheet automatic reel equipment that is used for camellia grafting, comprises workbench 1, is located at workbench 2 on workbench 1, is used for conveying the feed roller 11 of aluminum sheet and is used for rewinding after slitting The rewinding roller 12 of the aluminum sheet, the workbench 1 is provided with a working chamber 13; the two sides of the fixed frame 2 are respectively provided with a transmission assembly for conveying the aluminum sheet, and the fixed frame 2 is provided with a The moving seat 3 of the aluminum sheet and the first driver 21 for driving the moving seat 3 to move vertically, the bottom of the moving seat 3 is provided with at least one cutting knife group 30 corresponding to the size of the required aluminum sheet, so The working chamber 13 is provided with a fixed base 4 and a support seat 41 for supporting the aluminum sheet. Through the setting of the above-mentioned structure, the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com