Welding tray for welding gold brick/gold finger/touch tablet

A gold finger and soldering pad technology, applied in the field of soldering pads, can solve the problems of easy tinning, defective products, affecting appearance and use, etc., and achieve the effect of not easy to skew, less defective products, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

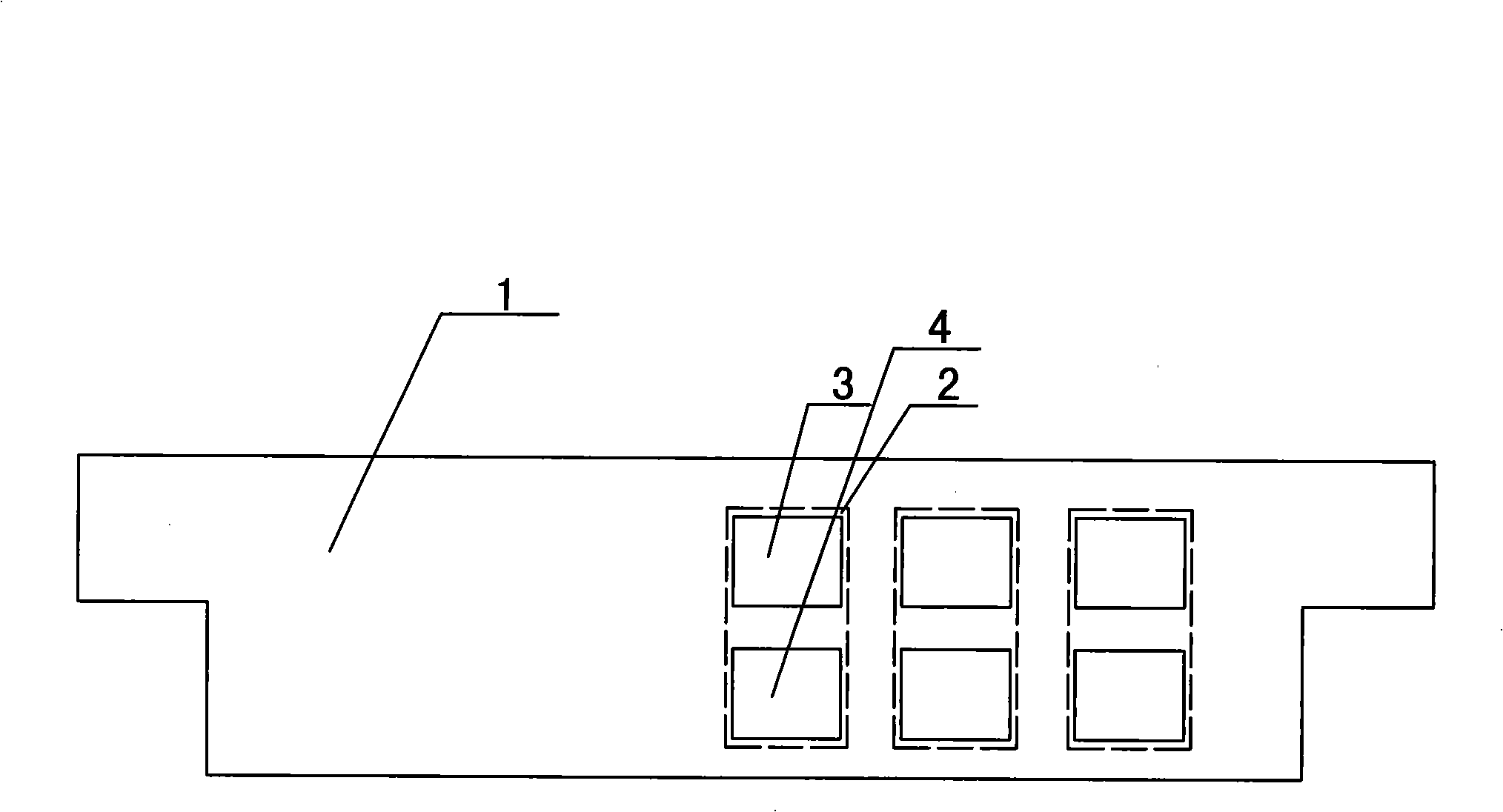

[0017] Please see attached figure 1 , the pad of the present invention mainly includes two parts, that is, the first pad part 3 and the second pad part 4. In this embodiment, the first soldering part 3 and the second soldering part 4 are arranged side by side, and the two soldering parts Form a rectangular pad, the insulating part between the first welding part 3 and the second welding part 4 can be blank or can be provided with insulating media such as green oil, black oil or red oil, and the two welding parts can be connected to the circuit board at the same time The circuit connection in, also can make one of them connect with the circuit in the circuit board. When soldering gold bricks / gold fingers / contacts, after the solder paste is printed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com