Method for purifying air

An air and carbon monoxide technology, which is applied in the fields of combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., and can solve the problems of energy consumption, low energy utilization rate, and low ignition point of activated carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

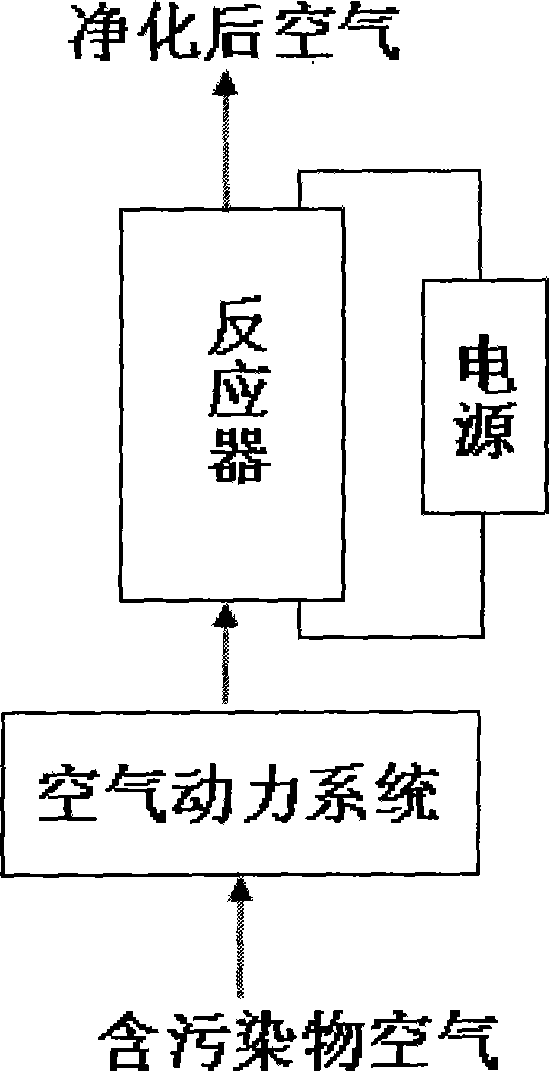

[0016] Purification process such as figure 1 shown. The reactor is filled with porous graphitized carbon adsorbent (specific surface area 370 m2 / g, pore volume 0.5 ml / g, particle size 40-60 mesh), and the filling volume is 500 ml. The pollutant in the air is toluene, the concentration is about 200 mg / m3. The fan air power system makes the polluted air flow into the reactor at a rate of 5 liters / minute, and within 10 days, the concentration of toluene in the outlet gas does not exceed 0.2 mg / m3. After 10 days, connect the outlet end of the reactor to the outdoors, or connect it to the incinerator, and start the fan aerodynamic system, adjust the power supply to a certain voltage, and heat the porous graphitized carbon adsorbent to 120°C in 15 minutes. its regeneration.

Embodiment 2

[0018] Purification process such as figure 1 shown. The reactor is filled with porous silicon carbide-supported palladium catalyst (specific surface area 140 square meters per gram, particle size 40-60 mesh), and the filling volume is 500 ml. The pollutant in the air is benzene, the concentration is about 260 mg / m3. Adjust the power supply to a certain voltage, make the porous silicon carbide energized and heat up to 210°C, turn on the fan air power system, and pump the polluted air into the reactor at a speed of 5 liters / minute, contact the catalyst and be catalyzed and destroyed, and the outlet gas The concentration of benzene should not exceed 0.1 mg / m3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ignition point | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com