Copper line-clad aluminum silicon carbide ceramic substrate applicable to radiation of high-power LED

A technology of aluminum silicon carbide and ceramic substrates, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of unsuitable aluminum nitride substrates, fragmentation, insufficient strength of anodized oxide layers, etc., and achieve good thermal stability, Simple preparation process and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

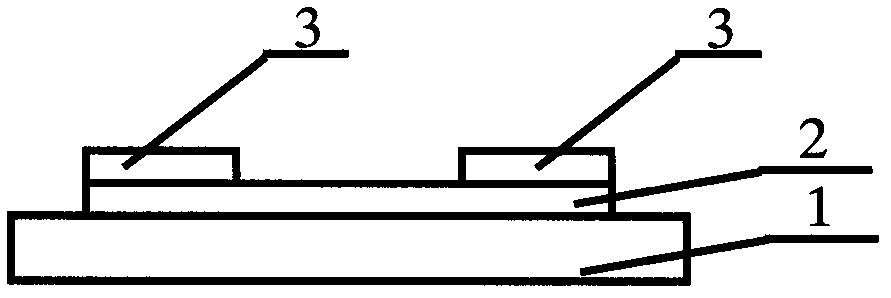

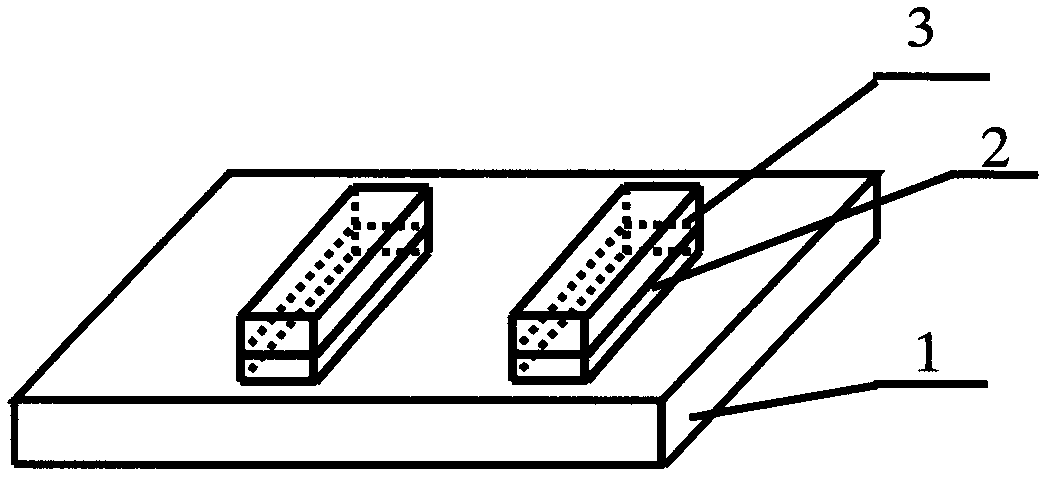

[0025] Implementation example 1: such as figure 1 and figure 2 As shown, a copper-clad circuit aluminum silicon carbide ceramic substrate for high-power LED heat dissipation is characterized in that: it is composed of an aluminum silicon carbide layer (1), a copper aluminum oxide layer (2) and a copper circuit (3); Copper-aluminum oxide layer (2) is on the layer (1), and copper wiring (3) is on the copper-aluminum oxide layer (2); the separation distance between the copper wiring (2) is 1 mm; the width of the copper wiring (2) is 1000 microns, and the height of the copper line (2) is 2 mm.

[0026] A copper-clad circuit aluminum silicon carbide ceramic substrate for high-power LED heat dissipation, comprising the following preparation steps: ① Weighing reagent (SiO 2 , coke and flux), fully mix these components;

[0027] ②Put the above mixture in a high temperature furnace for calcination, the calcination temperature is 1800°C, the rate of temperature increase is 50°C / hour...

Embodiment 2

[0033] Implementation example 2: such as figure 1 and figure 2 As shown, a copper-clad circuit aluminum silicon carbide ceramic substrate for high-power LED heat dissipation is characterized in that: it is composed of an aluminum silicon carbide layer (1), a copper aluminum oxide layer (2) and a copper circuit (3); The copper aluminum oxide layer (2) is on the layer (1), and the copper wiring (3) is on the copper aluminum oxide layer (2); the separation distance range between the copper wiring (2) is 1 mm; the copper wiring (2) The width is in the range of 500 microns, and the height of the copper lines (2) is in the range of 1 mm.

[0034]A copper-clad circuit aluminum silicon carbide ceramic substrate for high-power LED heat dissipation, comprising the following preparation steps: ① Weighing reagent (SiO 2 , coke and flux), fully mix these components;

[0035] ②Put the above mixture in a high-temperature furnace for calcination, the calcination temperature is 2000°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com