Preparation method of low-temperature sintering acid and alkali resistant porous silicon carbide ceramic film

A technology of porous silicon carbide and low-temperature sintering, which is applied in the field of inorganic membrane separation materials and inorganic porous materials, and can solve problems such as bending, poor alkali resistance, and mismatching thermal expansion coefficients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

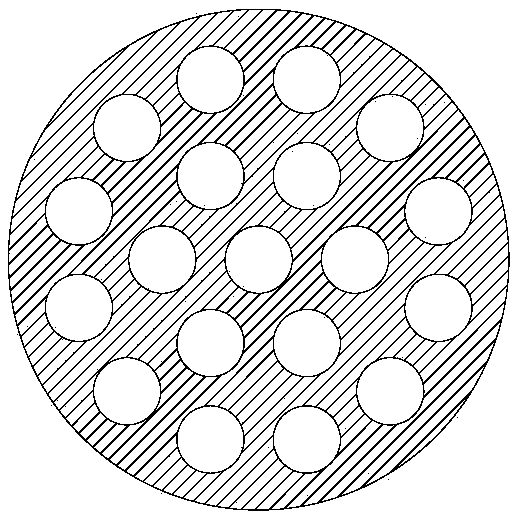

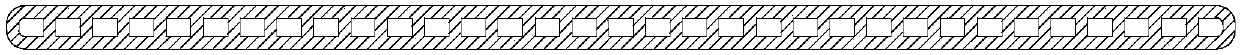

[0046] Blend 45μm silicon carbide particles, sintering aids, carboxymethyl cellulose, graphite powder, and tung oil with water and ethanol (V / V=3:2) in a mass percentage ratio of 85:5:3.0:5.5:1.5 In the solvent, the mixed solvent accounts for 24wt% of the total amount. Dry mix in a strong mixer for 30 minutes, add solvent and wet mix for 120 minutes, and then vacuum mud once at -0.95MPa, pack the refined mud in a vacuum bag, and store it at room temperature 24 hours, before opening the tube, practice the mud again in vacuum. The extruded mud is a tubular porous silicon carbide ceramic membrane mud with an outer diameter of 32mm, a channel diameter of 4.2mm, 19 holes, and a length of 1016mm. The extrusion pressure is 10Mpa and the extrusion speed is 20mm / s. The mud billet was dried in the room for 24 hours, and the acid and alkali resistant porous silicon carbide ceramic support body was obtained by drying.

[0047] Mix 15 μm silicon carbide whiskers with sintering aid, carbox...

Embodiment 2

[0051] Blend 62 μm silicon carbide particles, sintering aids, carboxymethyl cellulose, graphite powder, and tung oil agent in water and ethanol (V / V=3:2) in a mass percentage ratio of 82:8:3.5:5.0:1.5 In the mixed solvent, the mixed solvent accounts for 21wt% of the total amount. Dry-mix in a strong mixer for 30 minutes, add solvent and wet-mix for 120 minutes, and then vacuum mud once at -0.95MPa, pack the trained mud in a vacuum bag, and store it in a vacuum bag at room temperature. Keep it dry for 24 hours, and vacuum the mud again before opening the tube. The extruded mud is a tubular porous silicon carbide ceramic membrane mud with an outer diameter of 32mm, a channel diameter of 4.2mm, 19 holes, and a length of 1016mm. The extrusion pressure is 8.5Mpa and the extrusion speed is 30mm / s. The mud is dried indoors for 24 hours, then transferred to an oven, and dried to obtain an acid and alkali resistant porous silicon carbide ceramic support.

[0052] Mix 45 μm silicon car...

Embodiment 3

[0055] Blend 122 μm silicon carbide particles, sintering aids, carboxymethyl cellulose, graphite powder, and tung oil with water and ethanol (V / V=3:1) in a mass percentage ratio of 80:10:5.0:3.0:2.0 In the solvent, the mixed solvent accounts for 19wt% of the total amount. Dry-mix in a strong mixer for 20 minutes, add solvent and wet-mix for 100 minutes, and then vacuum mud once at -0.95MPa, pack the refined mud in a vacuum bag, and store it at room temperature 24 hours, before opening the tube, practice the mud again in vacuum. The extrusion die is a tubular porous silicon carbide ceramic membrane blank with an outer diameter of 32mm, a channel of 3.2mm, and 37 holes, with an extrusion pressure of 8Mpa and an extrusion speed of 50mm / s. The mud is dried indoors for 24 hours, then transferred to an oven, and dried to obtain an acid and alkali resistant porous silicon carbide ceramic support.

[0056]Mix 60 μm silicon carbide whiskers with sintering aid, carboxymethyl cellulose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com