Preparation method of flexible porous silicon carbide micro-nano fibrofelt

A technology of micro-nano fiber and porous silicon carbide, which is applied in the directions of fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve the problem of low yield of spinning fiber, the preparation method of flexible porous silicon carbide micro-nano fiber mat, It is not suitable for large-scale preparation and other problems, and achieves the effects of good flexibility, small fiber diameter and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

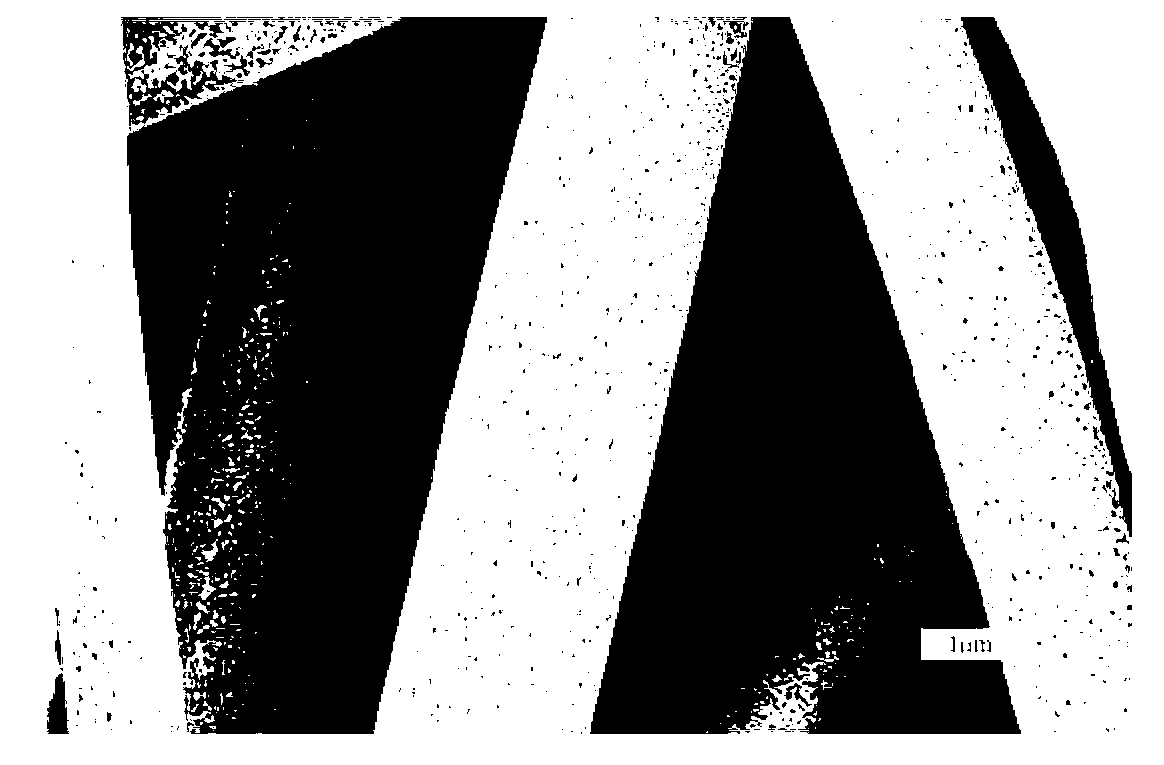

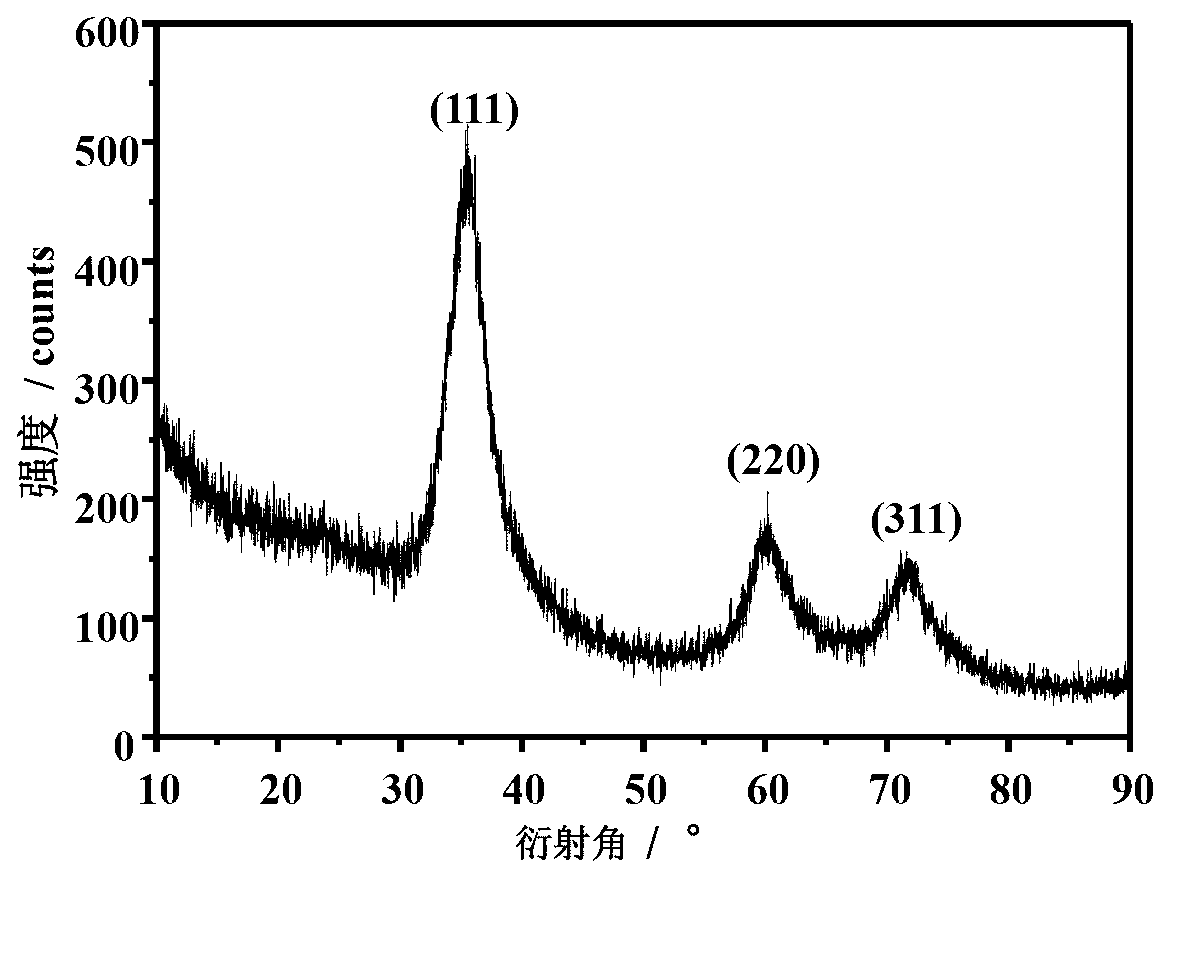

[0021] Mixed solvents of xylene, tetrahydrofuran and dimethylformamide were prepared at a volume ratio of 3:1:1. 5.0 g of polyaluminocarbosilane was added to 5.0 g of the mixed solvent and fully stirred for 4 hours to obtain a polyaluminocarbosilane solution with a concentration of 50 wt%. Place the solution for 8 days, put it into a glass syringe, the spinneret is 8# metal needle, under the conditions of output voltage 18kV, injection flow rate 2.0mL / h, roller accepting distance 8cm, humidity 40%, room temperature Electrospinning was carried out, and a flexible porous polyaluminocarbosilane fiber felt was obtained after spinning for 3 hours; then, in an air atmosphere, the temperature was raised to 200°C at a heating rate of 10°C / min and kept for 2h for oxidative cross-linking, and finally at 1300°C, high-purity nitrogen After the atmosphere treatment for 1 hour, a flexible porous silicon carbide micro-nano fiber mat is obtained, the fiber diameter is distributed around 1.5 μ...

Embodiment 2

[0024] Prepare a mixed solvent of xylene and dimethylformamide at a volume ratio of 7:3. 6.0 g of polyaluminocarbosilane was added to 4.0 g of the mixed solvent and stirred thoroughly for 6 hours to obtain a polyaluminocarbosilane solution with a concentration of 60 wt%. After placing the solution for 5 days, put it into a glass syringe, the spinneret is 8# metal needle, and carry out electrospinning at room temperature at an output voltage of 20kV, an injection flow rate of 2.0mL / h, a flat aluminum foil collection distance of 10cm, and a humidity of 60%. Silk, after spinning for 3 hours, a flexible porous polyaluminocarbosilane fiber felt was obtained; then, in an air atmosphere, the temperature was raised to 200°C at a heating rate of 15°C / min and kept for 2h for oxidative cross-linking, and finally treated at 1200°C in a high-purity nitrogen atmosphere for 2h , to obtain a flexible porous silicon carbide micro-nano fiber mat.

Embodiment 3

[0026] Prepare a mixed solvent of toluene, acetone and ethanol at a volume ratio of 3:1:1. Weighing 6.5 g of polycarbosilane was added to 3.5 g of mixed solvent and stirred thoroughly for 6 hours to obtain a polycarbosilane solution with a concentration of 65 wt%. After placing the solution for 7 days, put it into a glass syringe, the spinneret is a 12# metal needle, and the output voltage is 25kV, the injection flow rate is 1.5mL / h, the receiving distance of the drum is 12cm, the humidity is 50%, and it is carried out at room temperature. Electrospinning, after spinning for 2.5 hours, a flexible porous polycarbosilane fiber felt was obtained; then, in an air atmosphere, the temperature was raised to 180°C at a heating rate of 10°C / min and kept for 2h for oxidative cross-linking, and finally at 1000°C in a high-purity nitrogen atmosphere After 1 hour of treatment, a flexible porous silicon carbide micro-nano fiber mat is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com